Rough end yarn opener

An opener and tail yarn technology, applied in textiles and papermaking, textile decomposition and recovery, decomposition of fibrous substances, etc., can solve problems such as labor-intensive, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the patent of the present invention is described in more detail.

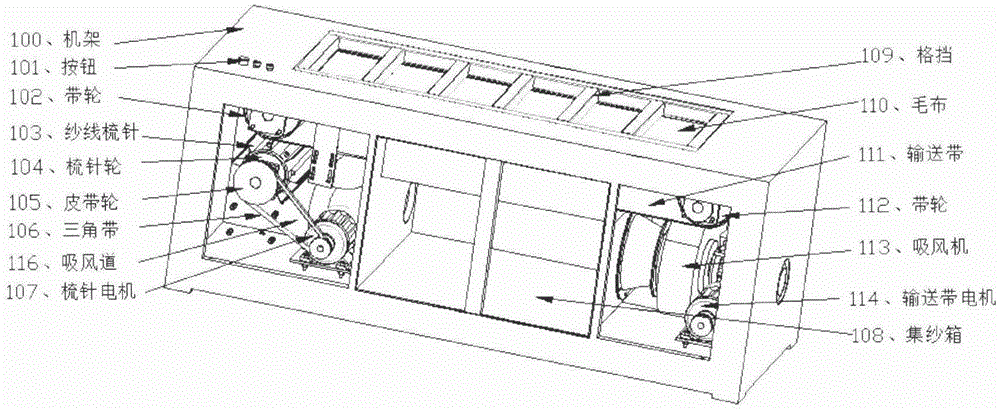

[0017] When it is necessary to open the thick tail yarn, the patent thick tail yarn opener of the present invention: as figure 1 As shown,.

[0018] Turn on the power button 101, the conveyor belt motor 114, the needle motor 107, the suction fan 114, and start working

[0019] The yarn rod that will loosen is put into block 109, li respectively. The conveyor belt motor 114 drives the conveyor belt 111 and the felt 110 to rotate counterclockwise to drive the roving tail thread end to peel off the roving rod.

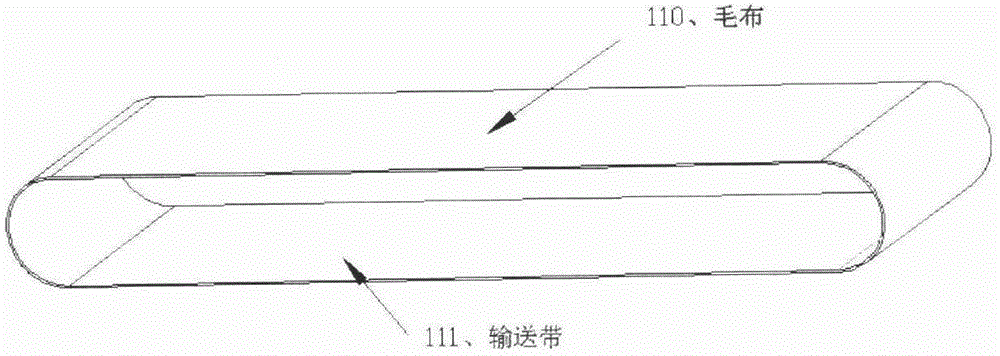

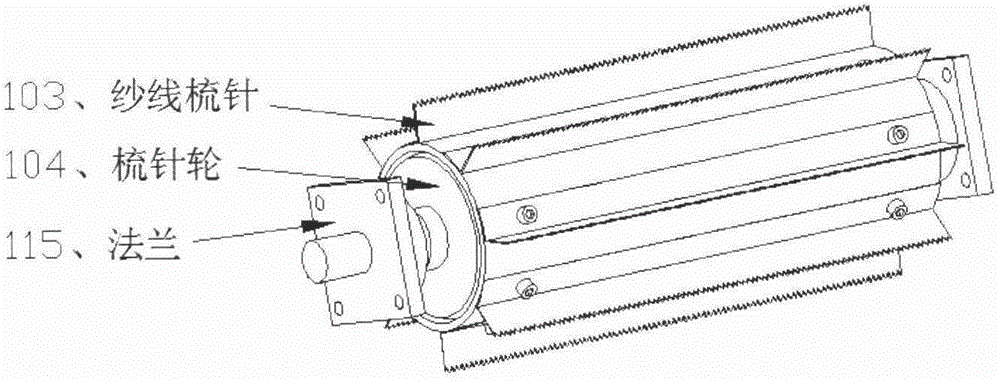

[0020] Such as figure 2 As shown, the stripped roving is conveyed by conveyor belt 111, and felt 110, to, as image 3 Shown, card wheel 104, and yarn card needle 103 places.

[0021] Such as figure 1 As shown, the carding motor 107 drives the V-belt 106, the pulley 105, the carding wheel 104, and the yarn carding needle 103, and rotates counterc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com