Well cementing slurry free liquid control agent, preparation method and application thereof

A technology for cementing cement slurry and control agent, which is applied to chemical instruments and methods, compositions of drilling holes, etc., can solve the problem of large amount of liquid silicon added, and achieve the effects of less usage, simple preparation method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

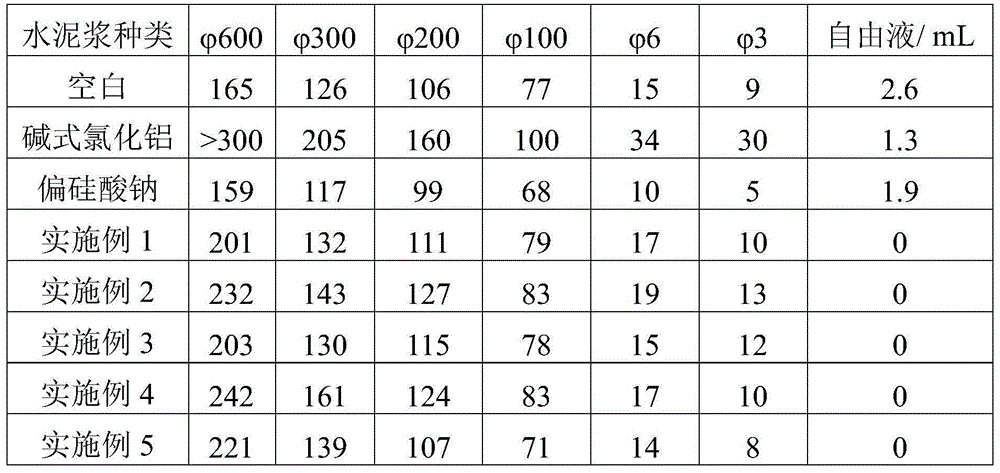

Examples

Embodiment 1

[0031] Use raw material as follows (consumption is based on 100 parts by total weight):

[0032] Organic viscosity-lifting agent: 300 g of scleroglucan, accounting for 30 parts;

[0033] Inorganic gelling agent: 200g of basic aluminum chloride, accounting for 20 parts;

[0034] Inorganic thickener: micro silicon 498g, accounting for 49.8 parts;

[0035] Boric acid 2g, accounting for 0.2 parts.

[0036] Preparation method: mix the above-mentioned four raw materials according to the above-mentioned proportions, and then dry them in an oven at 80°C for 24 hours to obtain the free liquid control agent for cementing slurry of the present invention.

[0037] Weigh 500g of oil well cement, 215g of water, 0.5g of defoamer, 5g of fluid loss reducer, and 5g of the free liquid control agent for cementing slurry obtained above. Mix oil well cement and cement slurry with free liquid control agent to form mixed ash; put water, fluid loss reducer and defoamer in a mixing container, and st...

Embodiment 2

[0039] Use raw material as follows (consumption is based on 100 parts by total weight):

[0040] Organic sticky agent: xanthan gum 50g, accounting for 5 parts; scleroglucan 350g, accounting for 35 parts;

[0041] Inorganic gelling agent: 200g of basic aluminum chloride, accounting for 20 parts;

[0042] Inorganic thickener: micro silicon 399g, accounting for 39.9 parts;

[0043] Boric acid 1g, accounting for 0.1 part.

[0044] Preparation method: mix the above-mentioned four raw materials according to the above-mentioned proportions, and then dry them in an oven at 80°C for 24 hours to obtain the free liquid control agent for cementing slurry of the present invention.

[0045] Weigh 500g of oil well cement, 215g of water, 0.5g of defoamer, 5g of fluid loss reducer, and 5g of the free liquid control agent for cementing slurry obtained above. Mix oil well cement and cement slurry with free liquid control agent to form mixed ash; put water, fluid loss reducer and defoamer in a...

Embodiment 3

[0047] Use raw material as follows (consumption is based on 100 parts by total weight):

[0048] Organic viscosity enhancing agent: sodium carboxymethylcellulose 300g, accounting for 30 parts; Wenlun glue 200g, accounting for 20 parts;

[0049] Inorganic gelling agent: basic aluminum chloride 100g, accounting for 10 parts;

[0050] Inorganic thickener: fly ash 100g, accounting for 10 parts, micro silicon 297g, accounting for 29.7 parts;

[0051] Boric acid 3g, accounting for 0.3 parts.

[0052] Preparation method: mix the above-mentioned four raw materials according to the above-mentioned proportions, and then dry them in an oven at 80°C for 24 hours to obtain the free liquid control agent for cementing slurry of the present invention.

[0053] Weigh 500g of oil well cement, 215g of water, 0.5g of defoamer, 5g of fluid loss reducer, and 10g of the free liquid control agent for cementing slurry obtained above. Mix oil well cement and cement slurry with free liquid control ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com