Rolling shaft conveying dolly

A technology for transporting trolleys and rolling shafts, which is used in motor vehicles, multi-axis trolleys, transportation and packaging, etc., can solve problems such as damage to rolling shafts, collisions of rolling shafts, affecting the normal use and sales of rolling shafts, and achieve a high level of safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

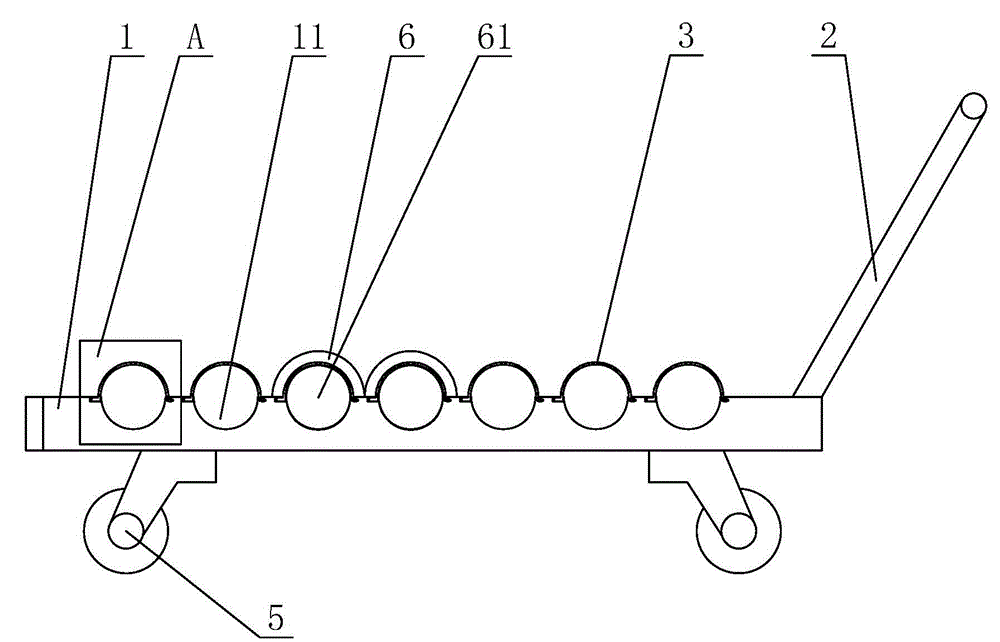

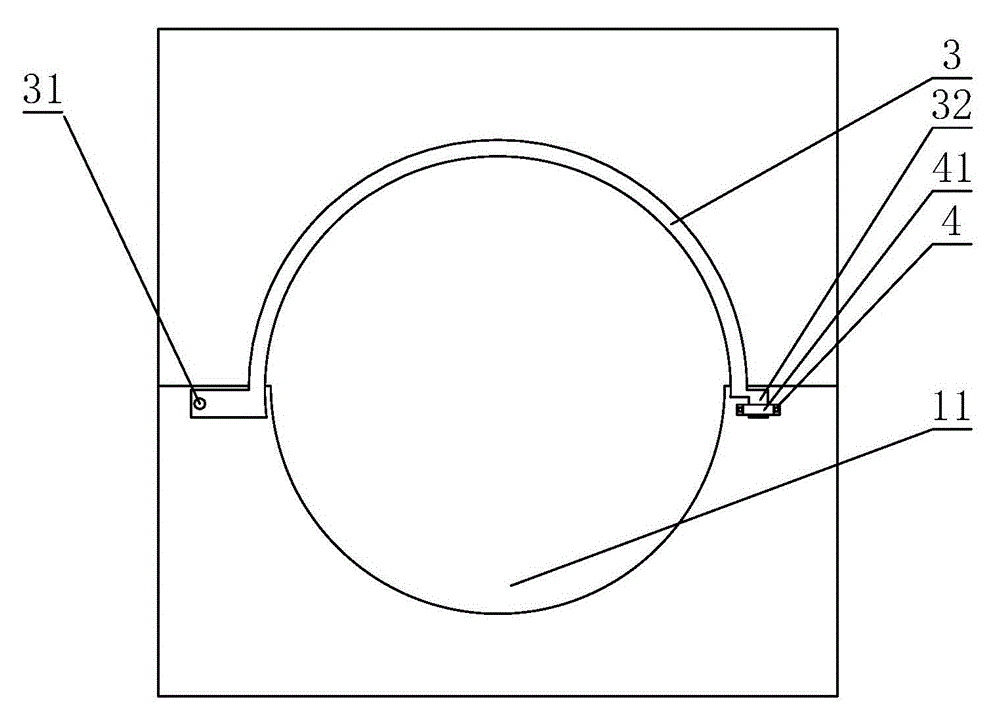

[0013] Such as figure 1 , figure 2 As shown, the rolling shaft transport trolley includes a bottom frame 1, a pull rod 2 and wheels, the pull rod 2 is fixed on the left and right side plates of the bottom frame 1, and the left and right side plates of the bottom frame 1 are also provided with Several arc-shaped grooves 11 are arranged in parallel, and each arc-shaped groove 11 side is equipped with an arc-shaped fixed card 3, and the diameter of the arc-shaped groove 11 is the same as that of the rolling shaft. The diameters of the bearings 61 on both sides of 6 are the same, the diameter of the arc-shaped fixed card 3 is slightly larger than the diameter of the bearing 61 of the rolling shaft 6, and one end of the arc-shaped fixed card 3 is rotatably fixed on the On the side plate of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com