Elastic bed board bar for bedstead

An elastic, bed board technology, applied in mattresses, applications, spring mattresses, etc., can solve the problems of inconvenient assembly, complex structure, disassembly and production of Simmons beds, increase air convection and service life, prevent deformation and The effect of breaking, reducing the cost of mattresses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

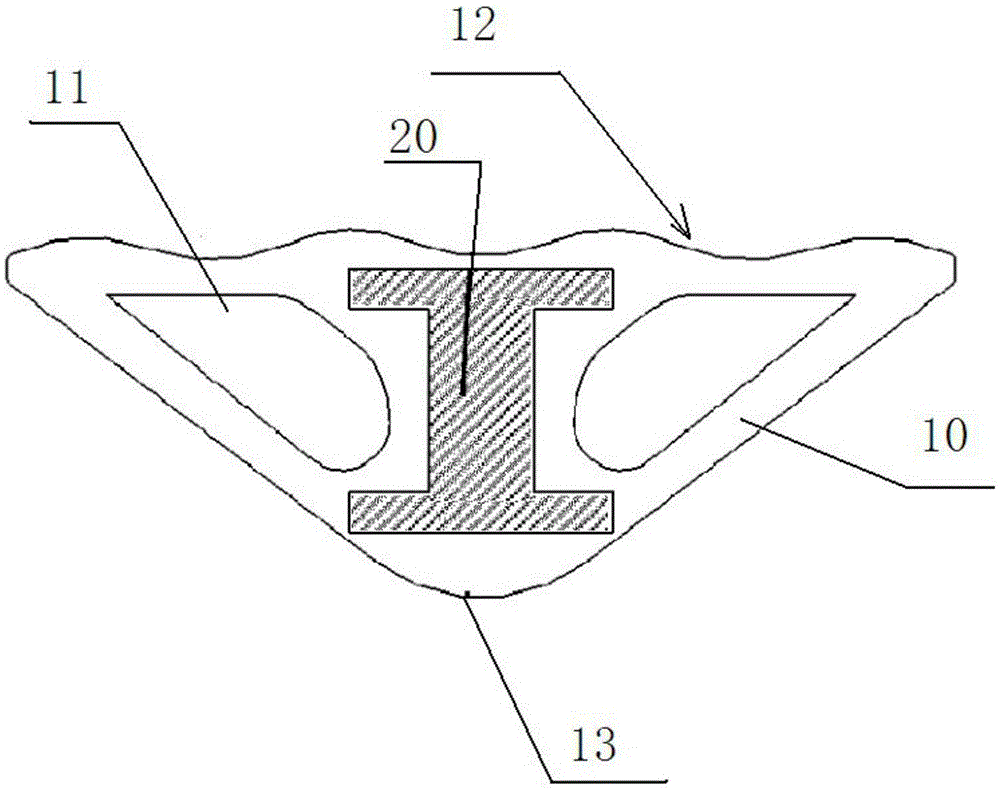

[0015] see figure 1 , an elastic bed slat for a bed frame in this embodiment, which includes a plastic slat body 10 for assembling into an elastic bed slat and a glass fiber core 20 arranged in the plastic slat body 10 to play a main bearing force; The plastic slat body 10 is a triangular prism, and its length is equal to the width of the assembled mattress. The plastic slat body is provided with three surfaces, that is, two inclined surfaces and a horizontal upper end surface as the next-to-body surface 12, on which the next-to-body surface 12 is provided with anti-skid Ribs, to increase the friction between it and the mattress it is set on.

[0016] The other two intersections of the plastic lath body 10 are provided with a circular arc transit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com