A hood for a range hood

A technology for range hoods and air outlet hoods, which is applied in the direction of removing oil fumes, applications, and household stoves. It can solve the problems of air injection and mixing, and the air outlet of the fan has no effect, so as to change the characteristics of the flow field and reduce noise. effect, the effect of increasing the mixing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

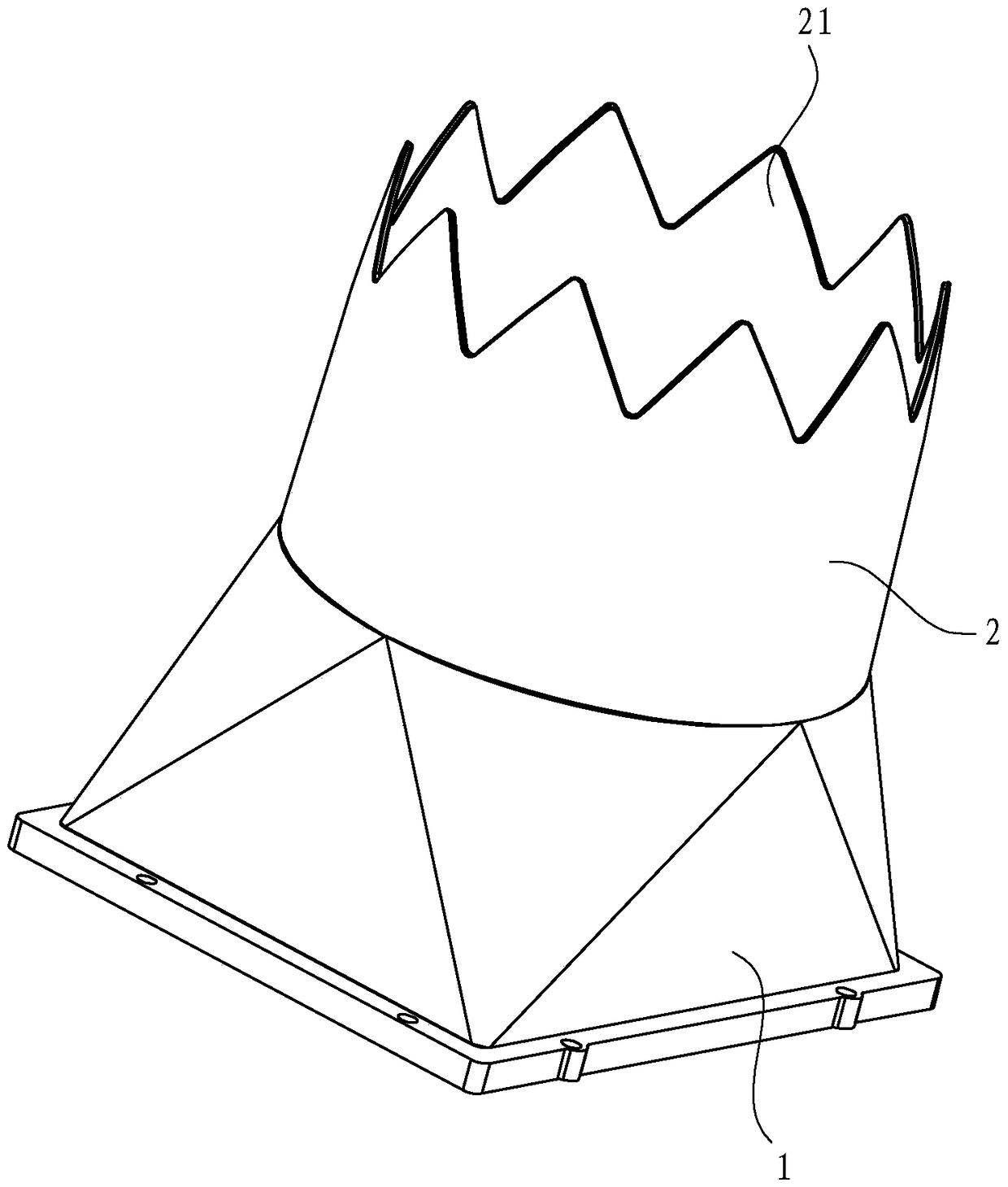

[0017] Such as figure 1 with figure 2 As shown, the air outlet hood for range hood in this embodiment includes a cover bottom 1 and a cover head 2, the cover bottom 1 is the air inlet end, the cover head 2 is the air outlet end, and the cover head The edge of the air outlet of 2 has a sawtooth structure, and the number of teeth of the sawtooth 21 can be set to 4-20.

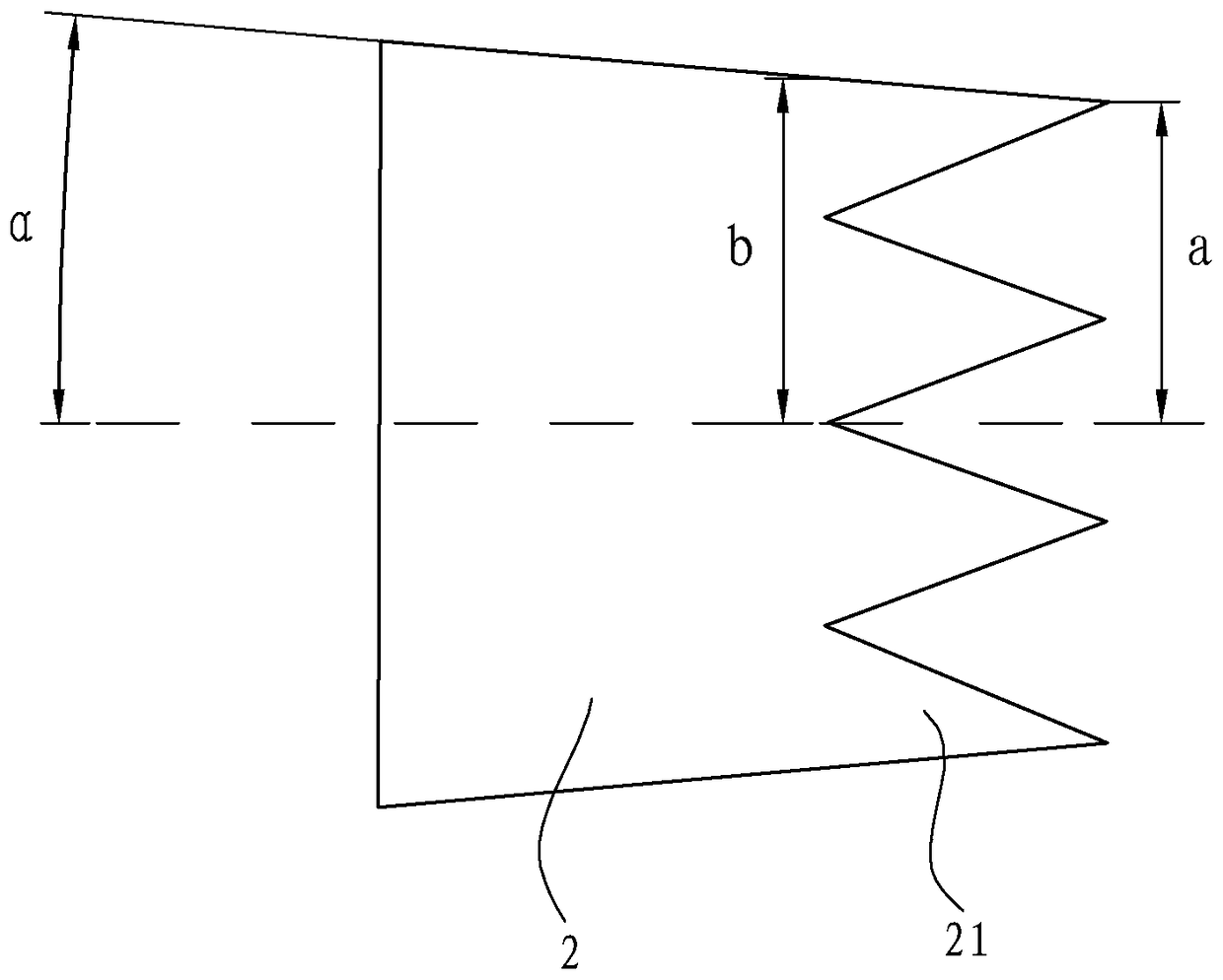

[0018] In this embodiment, the tip of the sawtooth 21 is pointed, and a V-shaped notch with a sharp angle is formed between two adjacent teeth of the sawtooth 21 . The cover head 2 gradually gathers from the bottom to the opening, and the angle α between the busbar of the cover head 2 and the central axis of the cover head 2 is 2°≤α≤20°, and the preferred value of α is The value is α=5°

[0019] In addition, the numerical relationship between the radius a of the circle where the tooth tip of the sawtooth 21 is located and the radius b of the circle where the bottom line of the tooth profile of the sawtooth 21...

Embodiment 2

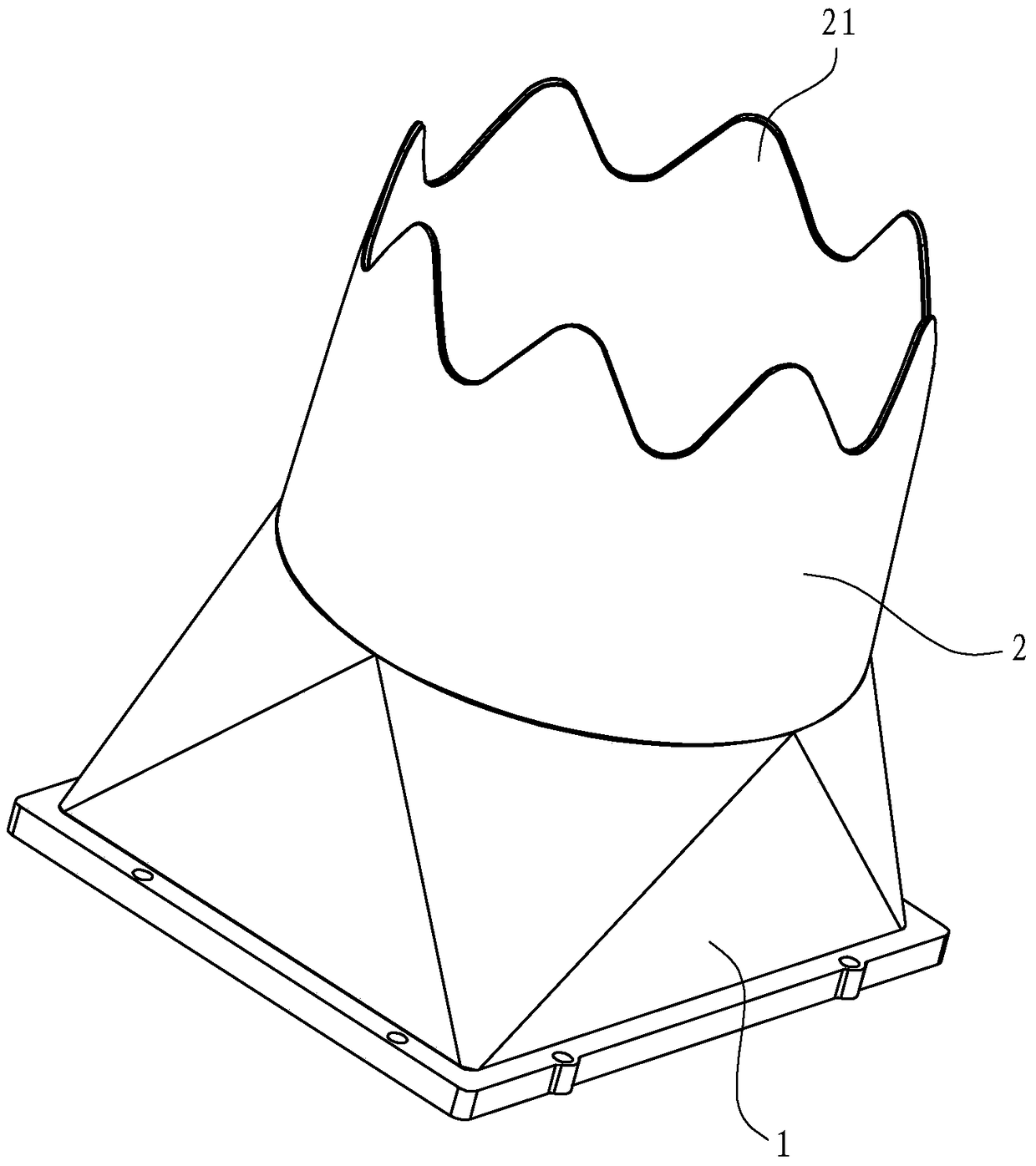

[0020] Embodiment two: if image 3 As shown, in this embodiment, the tips of the serrations 21 on the air outlet cover are arc-shaped, and the roots of two adjacent teeth of the serrations 21 are in a smooth transition. The rest of the structure of the air outlet hood in this embodiment is the same as that in Embodiment 1, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com