Timing chain wheel chamber shell

A timing sprocket and sprocket technology, which is applied to the casing, engine components, machine/engine, etc., can solve problems such as increased cost, chain skipping, and valve phase angle deviation, so as to save maintenance costs and prevent chain skipping. effect of teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

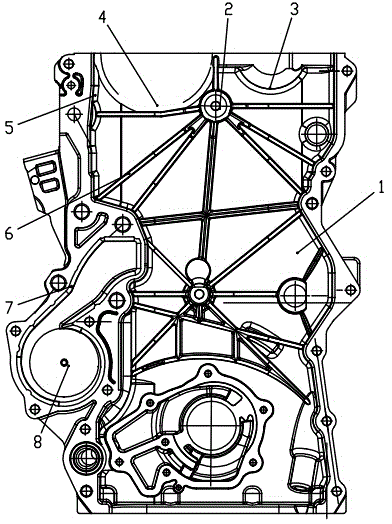

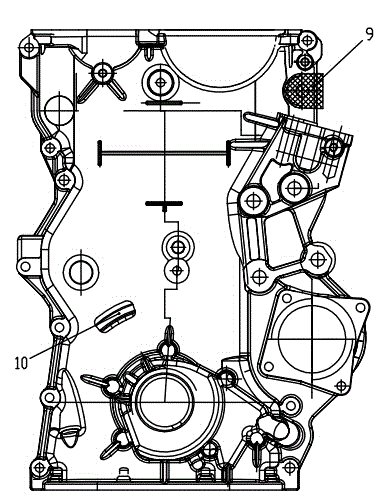

[0017] Such as Figure 1 to Figure 2 As shown, a timing sprocket chamber housing includes a sprocket cover 1, and connecting holes are arranged along the edge of the sprocket cover 1, and the top of the sprocket cover 1 is provided with an intake camshaft groove 3 and an air outlet Camshaft groove 4, the inlet camshaft groove 3 and the outlet camshaft groove 4 are respectively arranged on the outside and inside of the sprocket cover 1, and the inlet and outlet camshaft grooves are filled with semicircular rubber plugs , an air commutation guide wheel 2 is arranged between the two grooves, a chain guide groove 5 is arranged on the inner side of the sprocket cover 1 close to the outlet camshaft groove 4, and the sprocket cover 1 is also provided with Crankshaft sprocket 8, said crankshaft sprocket 8 is connected with volute guide groove 7, and an air filter 9 is also arranged near said outlet cam groove 4, and said air filter 9 is arranged on the outside of sprocket cover 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com