Small compactor

A tamping machine, small-scale technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problem of poor safety of using air tamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

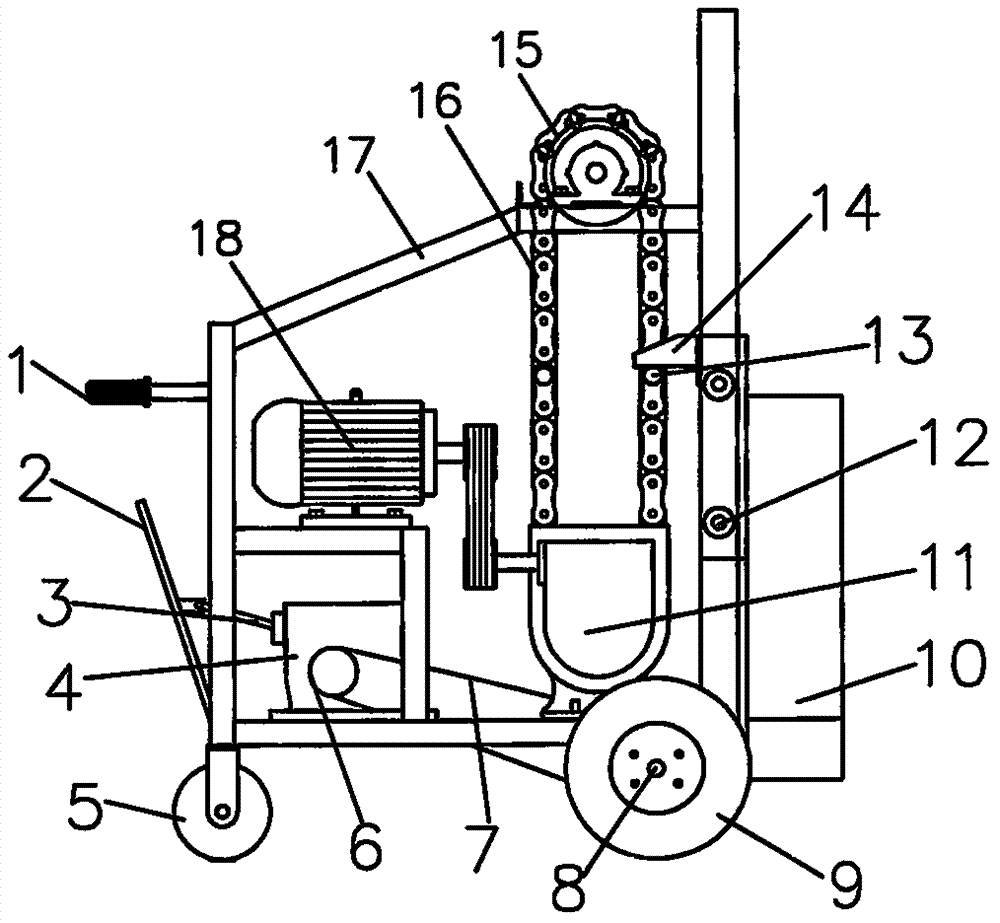

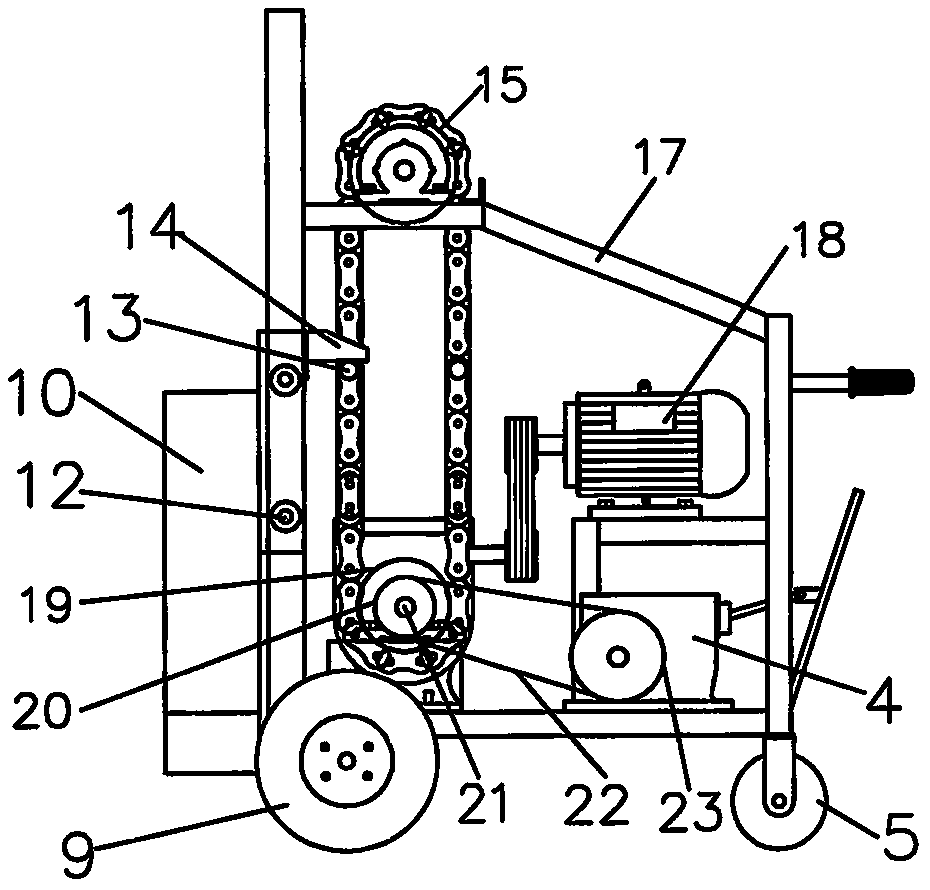

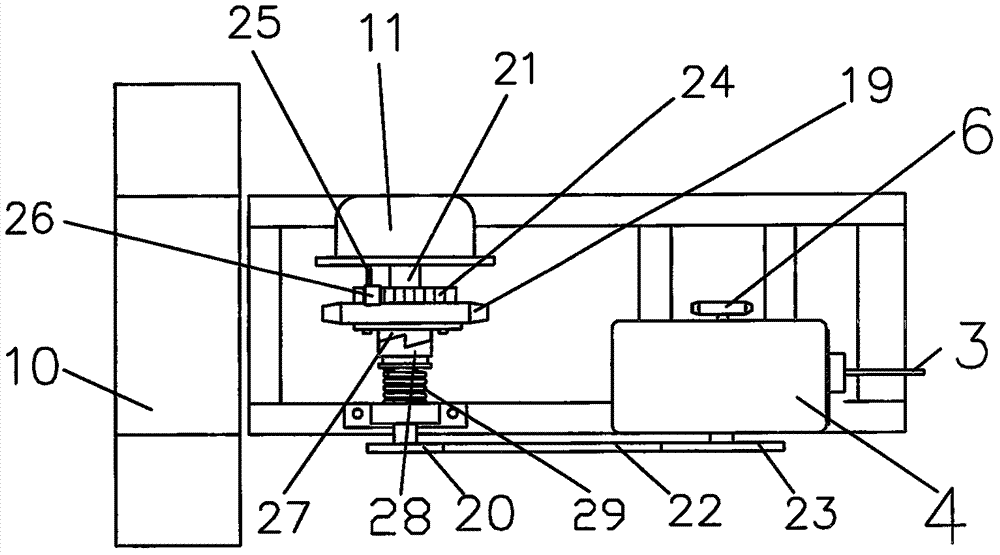

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the small ramming machine includes a frame 17, the front bottom of the frame 17 is rotatably connected with a walking wheel shaft 8, the two ends of the walking wheel shaft 8 are fixed with a walking wheel 9, and the middle position of the walking wheel shaft 8 is fixed with a walking chain wheel 30; the rear bottom of the frame 17 is rotatably connected with a universal wheel 5; the front upper part of the frame 17 is consolidated with a handle 1; There is a shift fork lever 3, the shift fork lever 3 is hinged with the middle part of the shift lever 2, and the lower end of the shift lever 2 is hinged with the frame 17; the input shaft of the travel gearbox 4 is fixed with a transmission passive sprocket 23, and the travel speed change On the output shaft of the box 4, a driving driving sprocket 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com