Glass bead conveying device of computer embroider machine

An embroidery machine and glass bead technology, applied in the mechanism of embroidery machine, embroidery machine, automatic control embroidery machine, etc., can solve the problems of easy glass bead sticking, complex structure, high cost, etc., and achieve good bead feeding reliability, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

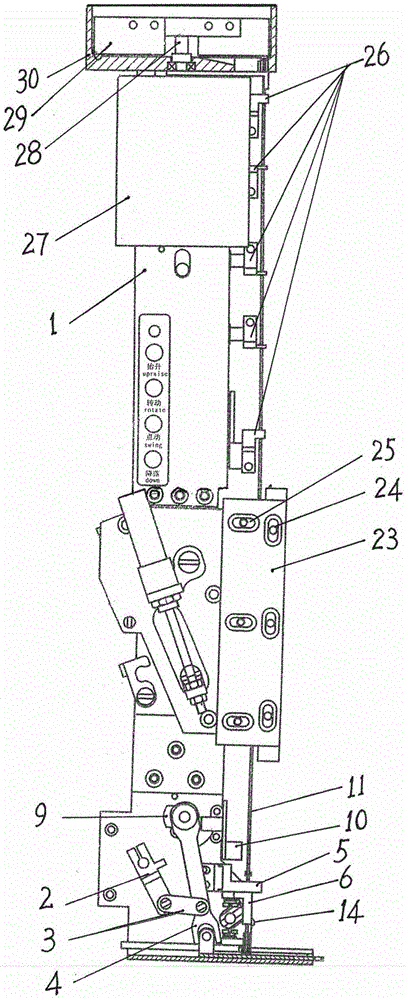

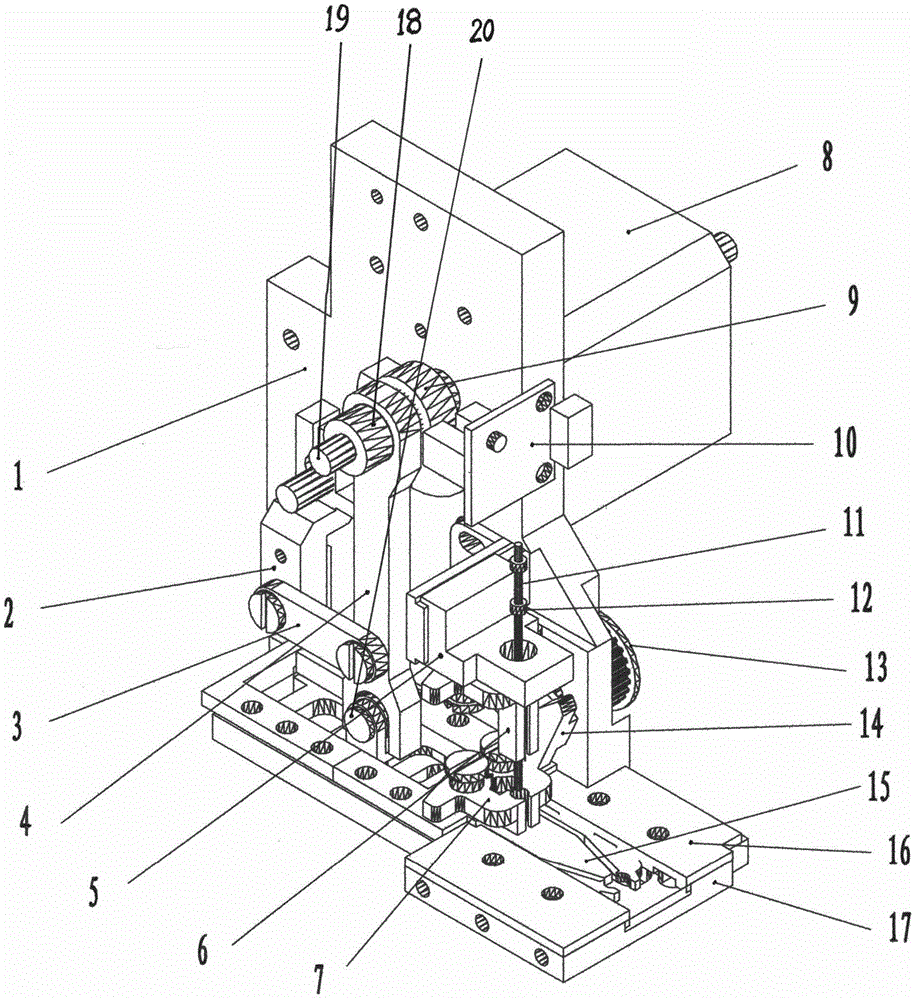

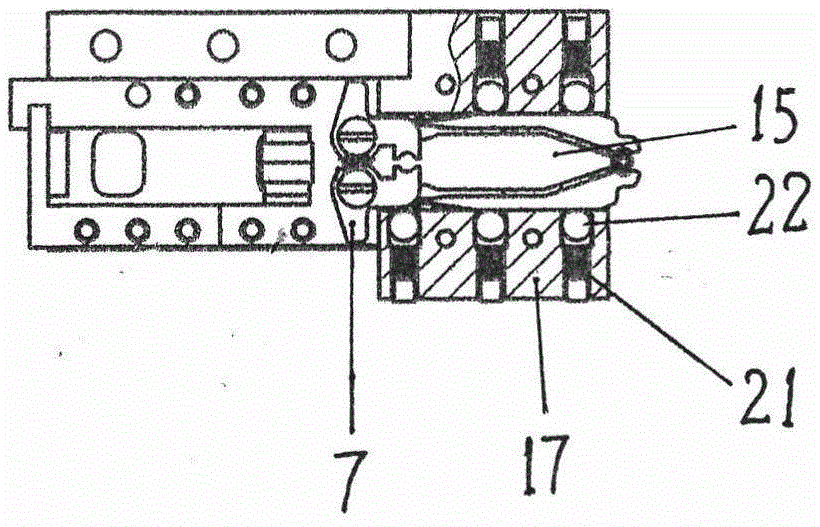

[0013] Such as figure 1 The glass bead feeding device of the computerized embroidery machine shown includes a mounting plate 1, a bead feeding cylinder 30, a bead feeding impeller 29, a bead feeding track 11, a bead feeding control mechanism, and a feeding mechanism. The upper end of the plate 1 and the bottom of the bead barrel 30 are provided with a bead outlet hole, and the upper end of the bead delivery track 11 is located directly below the bead outlet hole. Above, the bead sending impeller 29 is located in the bead barrel 30 and is fixedly installed on the end of the bead feeding motor 28 shaft to stir the glass beads 12 so that the glass beads 12 can be reliably output from the bead outlet; the feeding mechanism is composed of the bottom plate 17, the feeding motor 8. Bead push plate 15, push plate feed mechanism and control signal device; , the two ends of the connecting rod 3 are respectively hinged with the rocker 2 and the rocker 4, the upper end of the rocker 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com