Improved beaming device for sizing machine

A sizing machine, an improved technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., to achieve the effect of easy installation and reduce product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

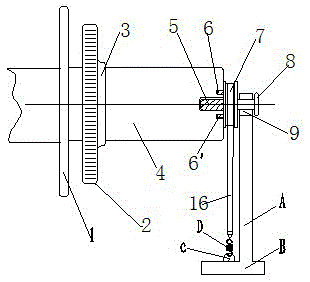

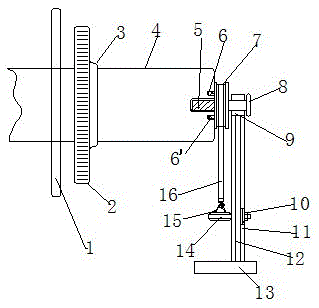

[0016] given in figure 1 , figure 2 In the existing sizing inverted shaft tension adjustment device, the lower end of the supporting column A is welded on the base B, the top of the supporting column A is provided with a semicircular groove, the bearing bush 9 is installed in the semicircular groove, and the left and right sides of the weaving shaft 4 A weaving shaft disk 1 is installed and fixed on the outer circle of the right end, with a gear 2, the center of the two ends of the weaving shaft 4 is provided with a hole, and a shaft head 5 is installed and fixed in the central holes at the left and right ends of the weaving shaft 4, and The snap ring 3 installs and fixes the gear 2 on the weaving shaft 4 on the right side of the weaving shaft disk 1; the two sides of the center hole at the right end are respectively provided with a first pin hole and a second pin hole, and the pulleys 7 are respectively set and fixed on the On the left and right ends of the weaving shaft 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com