Coating circulating system cleaning technology

A recycling system and coating technology, applied in the direction of spraying device, etc., can solve the problem of two-way cost waste, achieve the effect of saving cost, enhancing flexibility, and avoiding large-cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] The present invention will be further clarified below in conjunction with the drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" "Respectively refers to the direction toward or away from the geometric center of a particular component.

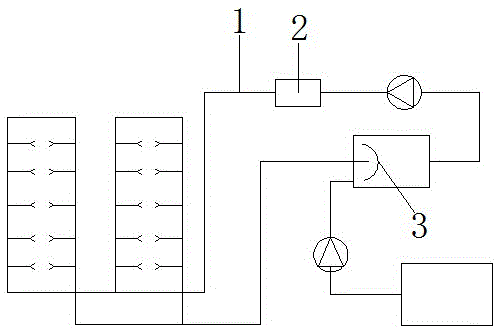

[0038] Such as figure 1 As shown, a coating recycling system cleaning technology is a set of oily to water-based coating recycling system cleaning technology, including the following steps:

[0039] (1) The first QX-Ⅱ solvent cleaning:

[0040] (1) Push out the paint in the system and press out the remaining paint in the pipeline with air until air is released from the return pipe 1;

[0041] (2) Injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap