Strength test fixture applicable to studs

A strength test, double-ended stud technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc. Advanced problems, to achieve the effect of convenient stress loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

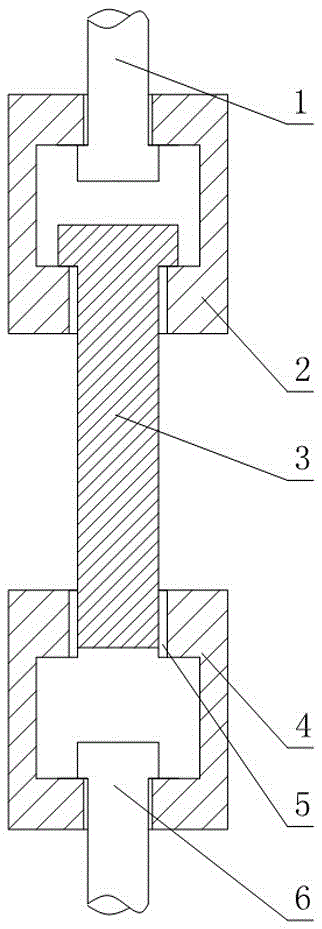

[0020] Such as figure 1 As shown, a strength test fixture suitable for double-ended studs includes a first block 2 and a second block 4, and the first block 2 and the second block 4 are respectively connected with a first pull rod 1 And the second pull rod 6, the first pull rod 1 is used for the fixed connection between the first block 2 and the hydraulic testing machine, and the second pull rod 6 is used for the fixed connection between the second block 4 and the hydraulic testing machine;

[0021] The first block 2 and the second block 4 are all provided with a T-shaped slot, the width of the bottom end of the T-shaped slot is greater than the width of the opening end, and the depth direction of the T-shaped slot on the first block 2 is the same as that of the first block 2. The axial direction of a pull rod 1 is parallel, and the depth direction of the T-shaped groove on the second block 4 is parallel to the axial direction of the second pull rod 6; both the first block 2 a...

Embodiment 2

[0025] Such as figure 1 As shown, this embodiment is further limited on the basis of Embodiment 1: in order to facilitate the uniformity of force on each point on the cross section of the first pull rod 1, the first block 2, the screw or the nut, the first pull rod 1 The axis of is collinear with the centerline of the T-shaped slot on the first clamping block 2 .

[0026] In order to facilitate the uniformity of the stress on the second pull rod 6, the second block 4, the screw rod or each point on the cross section of the nut, the axis of the second pull rod 6 is collinear with the center line of the T-shaped groove on the second block 4 .

[0027] In the absence of an auxiliary screw or nut, in order to make this fixture at least applicable to the tension test of a threaded rod with no nut end at both ends and a screw with a nut end at one end, T on the first block 2 A nut is arranged in the T-shaped slot and / or the T-shaped slot on the second block 4, and the nut is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com