Production method of seamless automobile door lock pull wire sheath

A technology for car door locks and production methods, which can be applied to other household appliances, household appliances, applications, etc., and can solve problems such as cracking at the thin seam, cracking at the bonded thin seam, and remodeling by heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

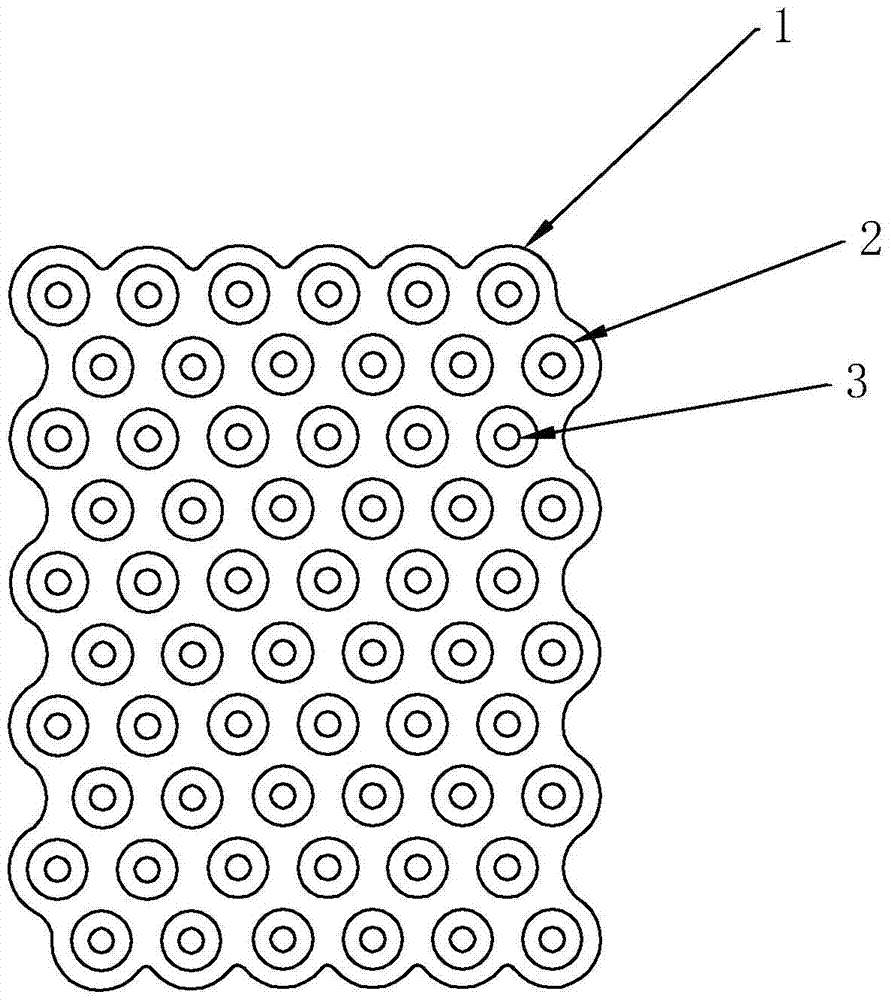

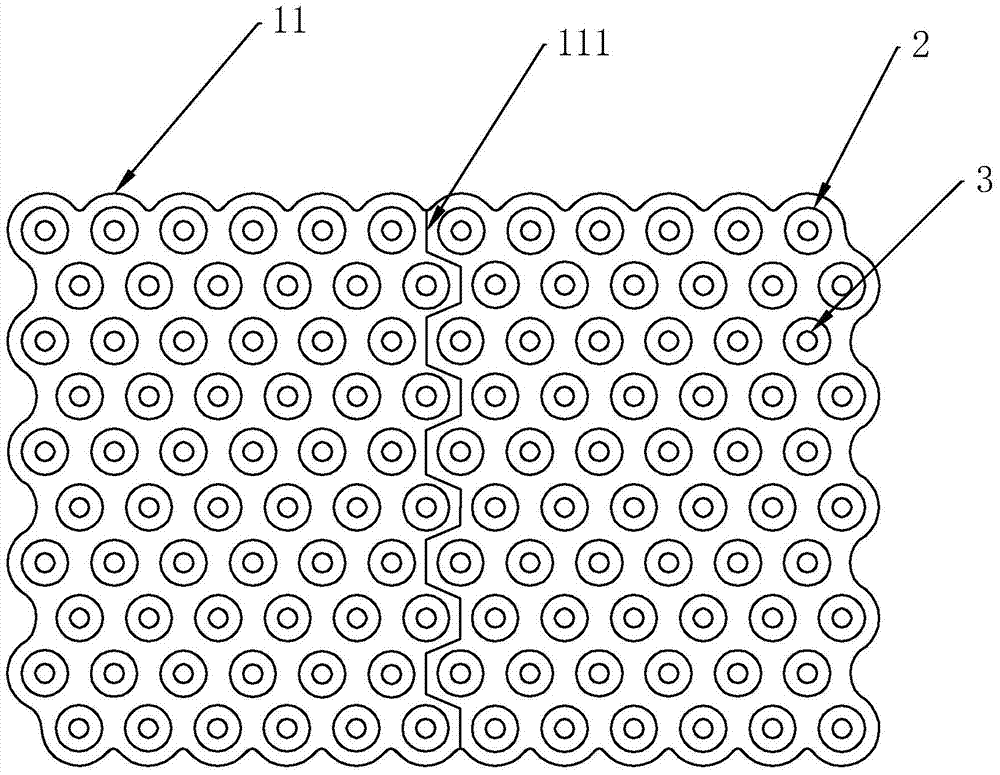

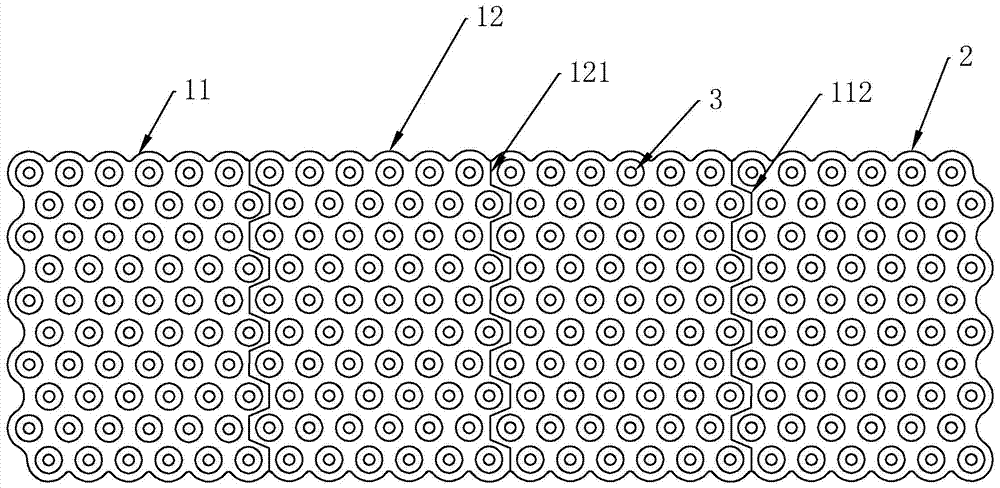

[0026] refer to Figure 1 to Figure 3 The embodiment of the production method of the seamless automobile door lock cable sheath of the present invention will be further described.

[0027] In this example, liquid CO2 foaming technology suitable for domestic large and medium-sized enterprises is adopted to produce a flat-top continuous foam with a foam density of about 14 kg / m3, a softer feel, a high open-cell structure, and good resilience As the raw material of the finished noose, the good highly porous structure and good resilience of the raw material are suitable for the needs of the present invention.

[0028] Specifically, a production method of a seamless automobile door lock pull wire sheath,

[0029] In the first step, according to the liquid CO2 foaming technology, a flat-top continuous polyurethane sponge can be foamed;

[0030] In the second step, according to the customer's requirements, after designing stamping dies of the size of the corresponding annular outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com