Method, device and system for controlling compressor

A technology of control algorithm and control circuit, which is applied in the field of compressor control, can solve the problems of high voltage ripple, lower system response speed, drop, etc., and achieve reduced input power ripple, high voltage ripple, and reduced energy storage capacitance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to an embodiment of the present invention, an embodiment of a method for controlling a compressor is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, Also, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

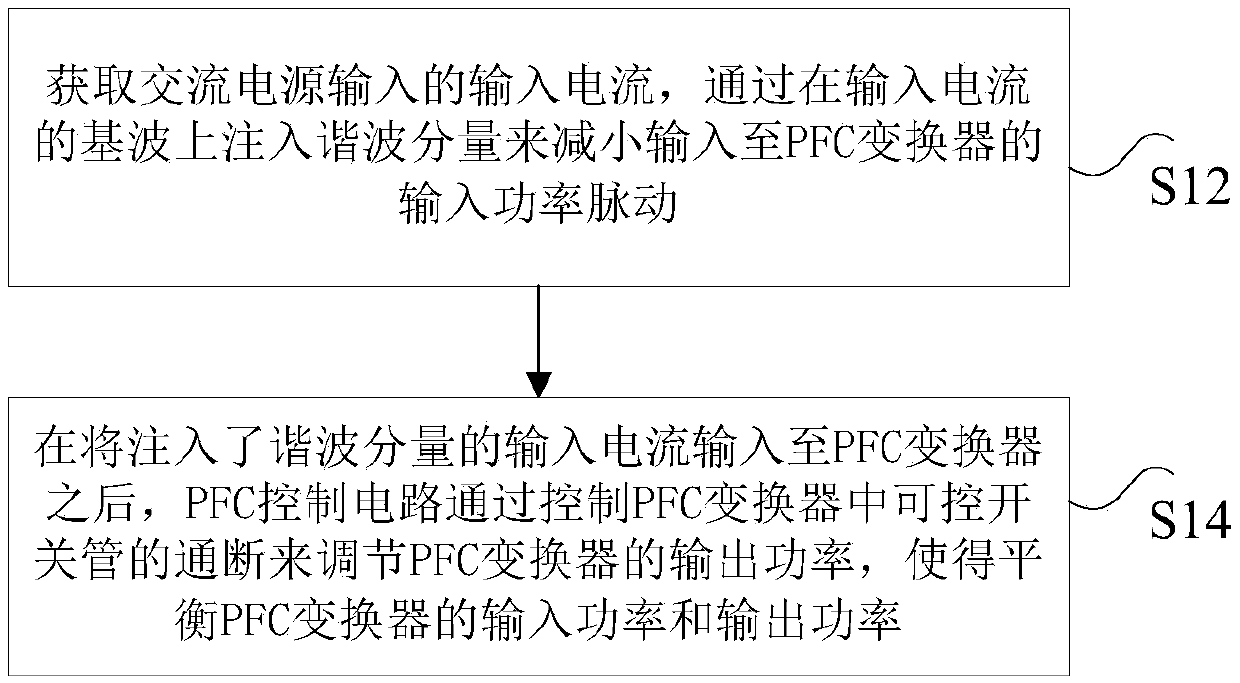

[0030] figure 1 is a flowchart of a method for controlling a compressor according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0031] Step S12, obtain the input current input by the AC power supply, and reduce the input power pulsation input to the PFC converter by injecting harmonic components on the fundamental wave of the input current, wherein the harmonic components include at least: third harmonic components and / or or the fifth ...

Embodiment 2

[0138] According to an embodiment of the present invention, an embodiment of a device for controlling a compressor is provided, such as Figure 6 As shown, the device includes: an acquisition module 61 and an adjustment module 63 .

[0139] Wherein, the obtaining module 61 is used to obtain the input current input by the AC power supply, and reduce the input power pulsation input to the PFC converter by injecting harmonic components on the fundamental wave of the input current, wherein the harmonic components include at least: the third harmonic wave components and / or fifth harmonic components.

[0140] The adjustment module 63 is used to adjust the output power of the PFC converter by controlling the on-off of the controllable switch in the PFC converter after inputting the input current injected with harmonic components into the PFC converter, so as to balance the PFC The input power and output power of the converter.

[0141] Specifically, the above PFC converter may be a...

Embodiment 3

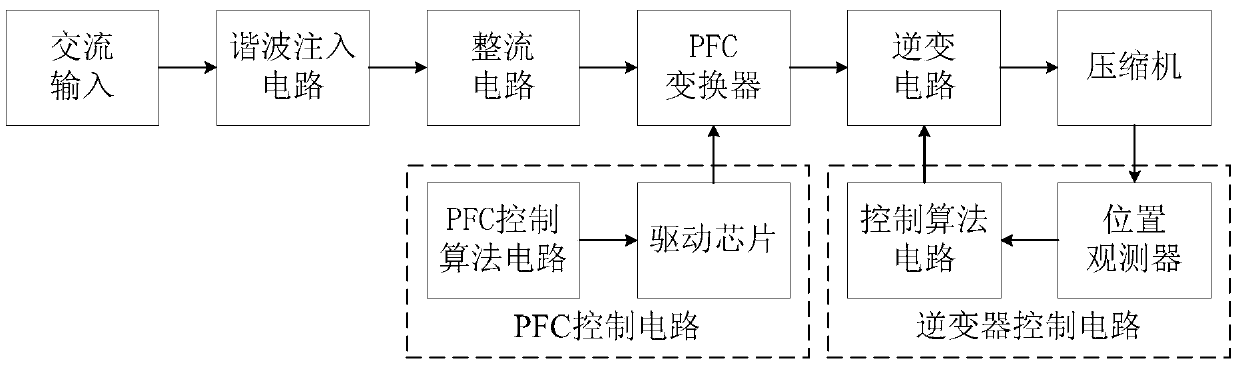

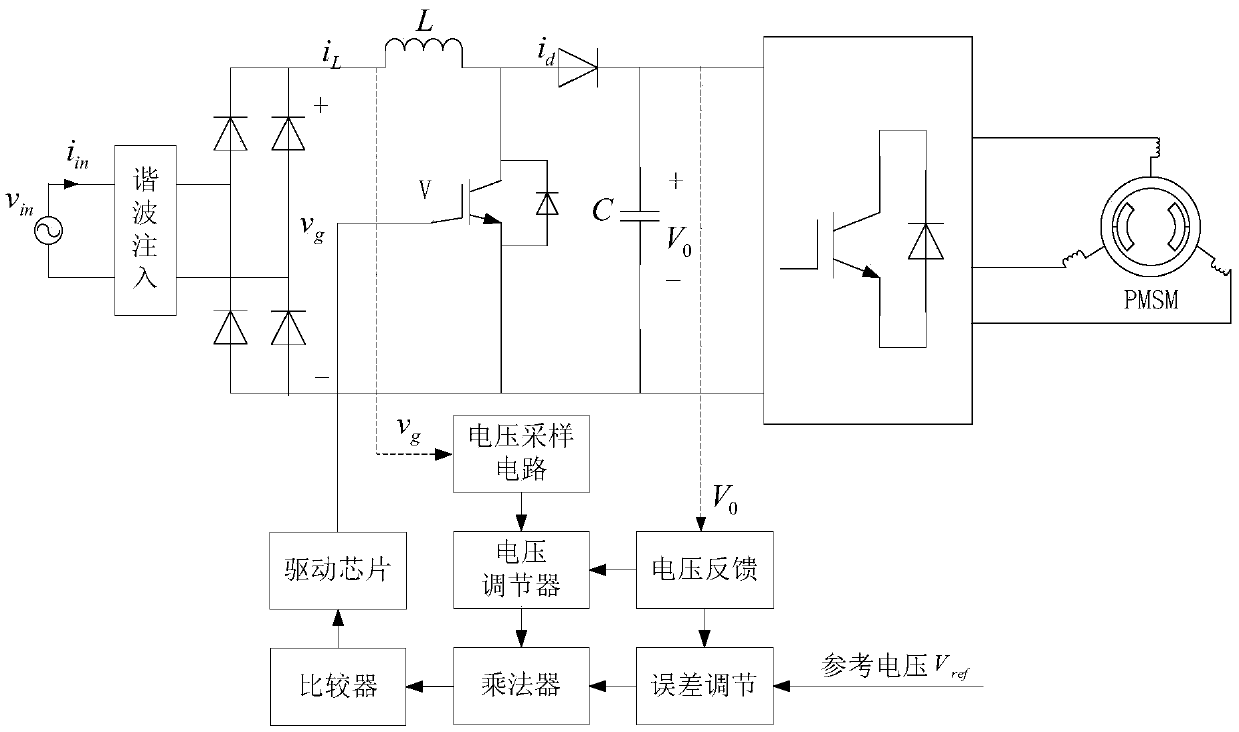

[0145] According to an embodiment of the present invention, a system embodiment for controlling a compressor is provided, such as Figure 7 As shown, the system includes: a harmonic injection circuit 71 , a PFC converter 73 , a PFC control circuit 75 and an AC power supply 77 .

[0146] Wherein, the harmonic injection circuit 71 is connected with the AC power supply 77, and is used to obtain the input current input by the AC power supply, and reduce the input power pulsation input to the PFC converter by injecting harmonic components on the fundamental wave of the input current, wherein , the harmonic component at least includes: the third harmonic component and / or the fifth harmonic component.

[0147] The PFC converter 73 is connected to the harmonic injection circuit 71, and is used to obtain an input current injected with a harmonic component.

[0148] Specifically, the above PFC converter may be a Boost type APFC (Active Power Factor Correction) converter.

[0149] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com