Linear motor and optimization and verification method for improving operation efficiency of the same

A technology of linear motors and primary coils, applied in AC motor control, electrical components, electromechanical devices, etc., can solve the problems of low operating efficiency of linear motors and the influence of motor operating efficiency, and achieve simple structure, convenient operation, and suppression of thrust fluctuations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

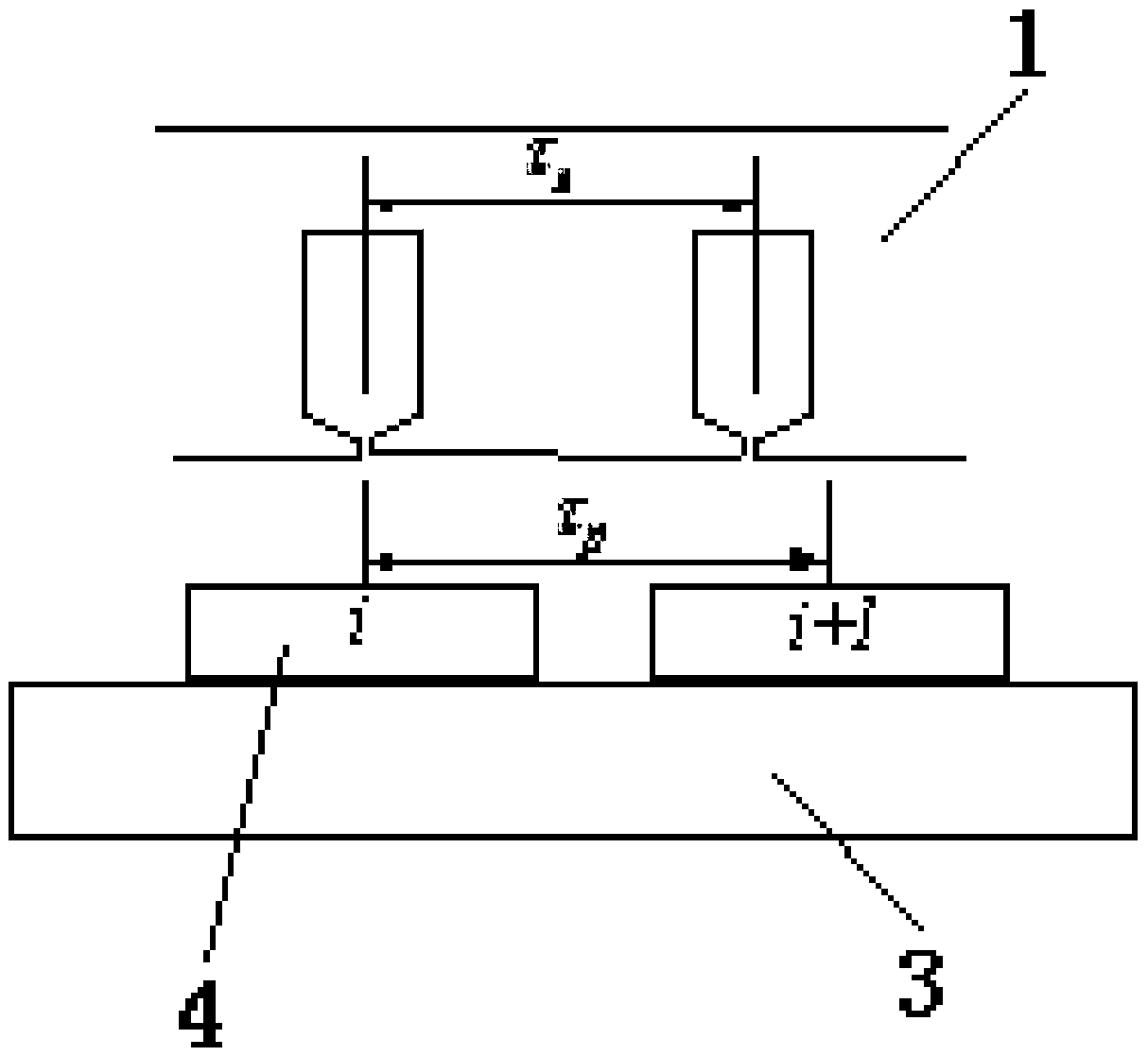

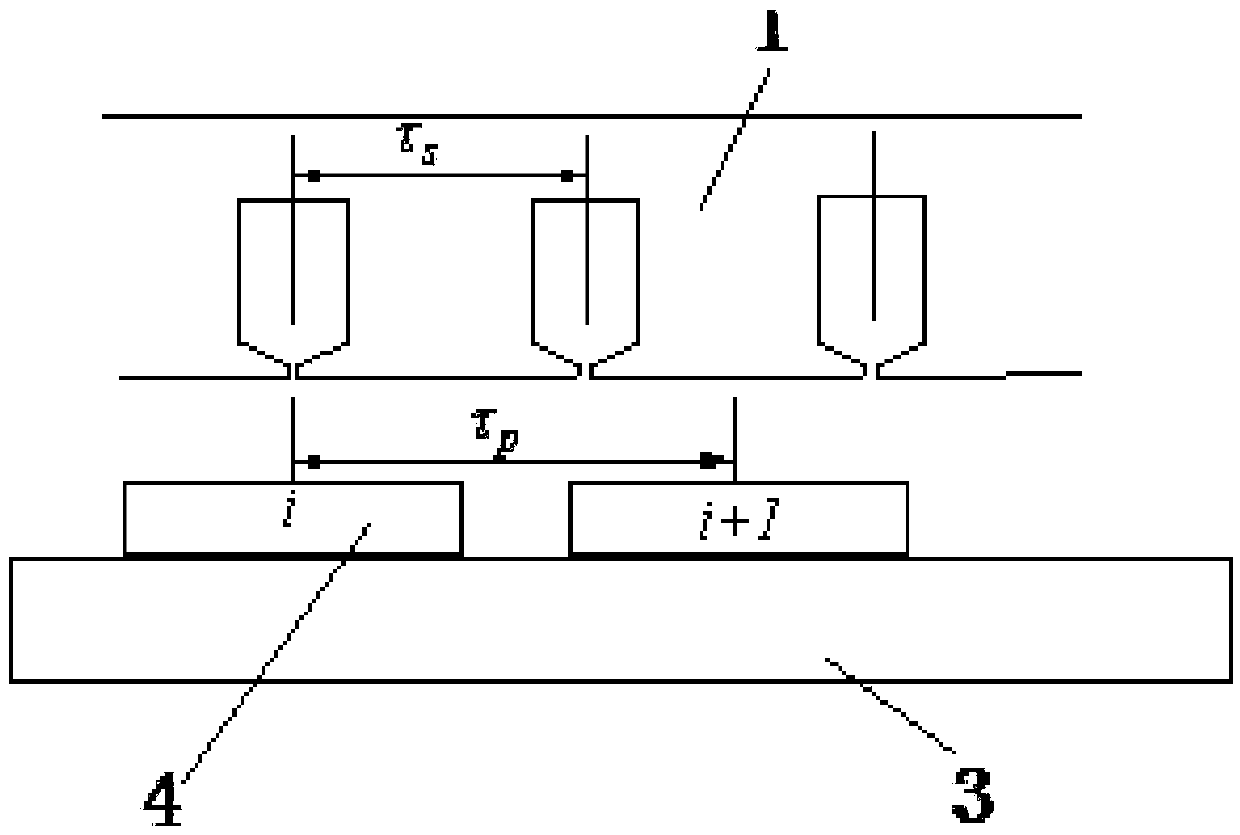

[0026] The cogging force is the force generated by the interaction between the permanent magnet and the iron core, and the cogging force exists even when the armature winding is not energized. The cogging force of a linear motor varies with the position between the motor's cogging and the permanent magnet, causing the thrust to fluctuate. The air gap permeability between the mover and the stator changes, and the magnetic field energy storage changes, thereby generating cogging force.

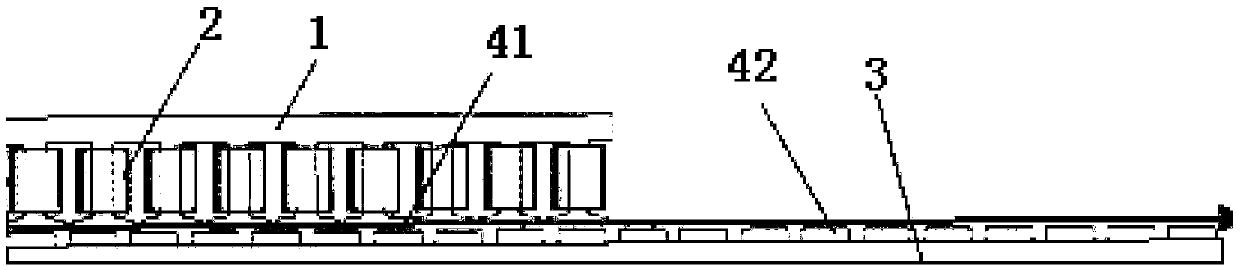

[0027] The linear motor of the present invention is a motor that can reduce thrust fluctuations and has small cogging force, such as figure 1 As shown, it includes primary iron core 1, primary coil 2, secondary iron core 3 and permanent magnet 4. The primary iron core 1 has a plurality of slots, and the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com