A Fiber Bragg Grating Pressure Sensor

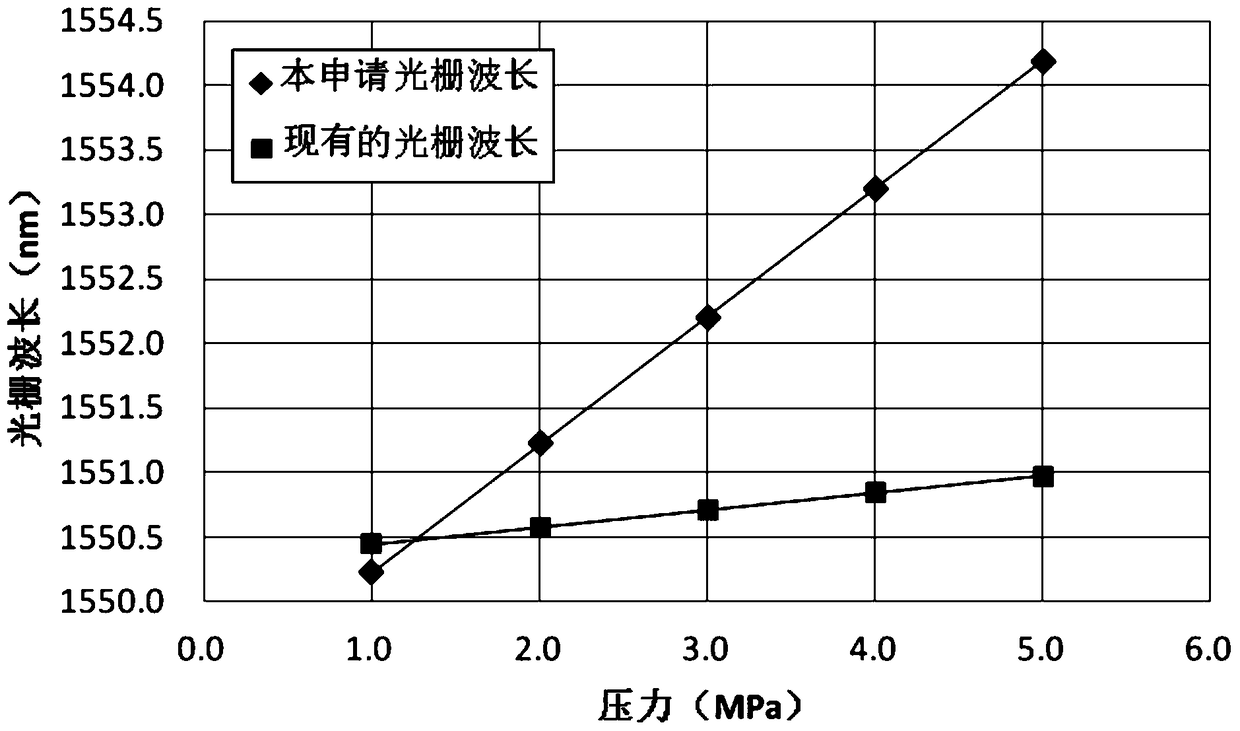

A technology of pressure sensor and optical fiber grating, which is applied in the field of pressure monitoring in pipelines/equipment, can solve the problem of low sensitivity, achieve the effect of improving sensitivity, improving measurement accuracy, and reducing random errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a fiber grating pressure sensor, which communicates with the pressure-tested pipeline, or the pressure-tested pipeline container, or the pressure-tested pipeline equipment, and is used for measuring the pressure-tested pipeline, or the pressure-tested pipeline container, or the pressure-tested pipeline The pressure in the pressure measuring pipeline equipment is tested.

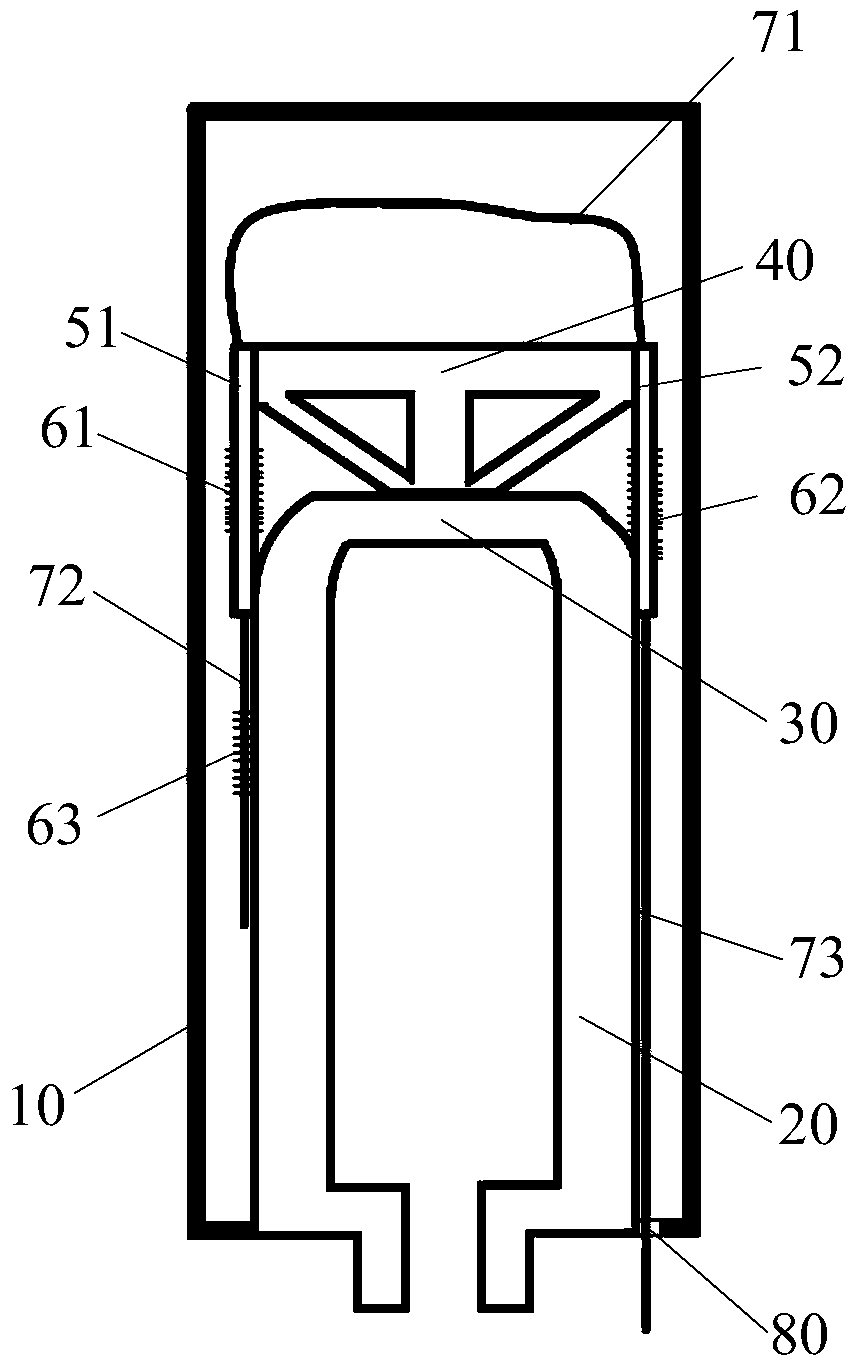

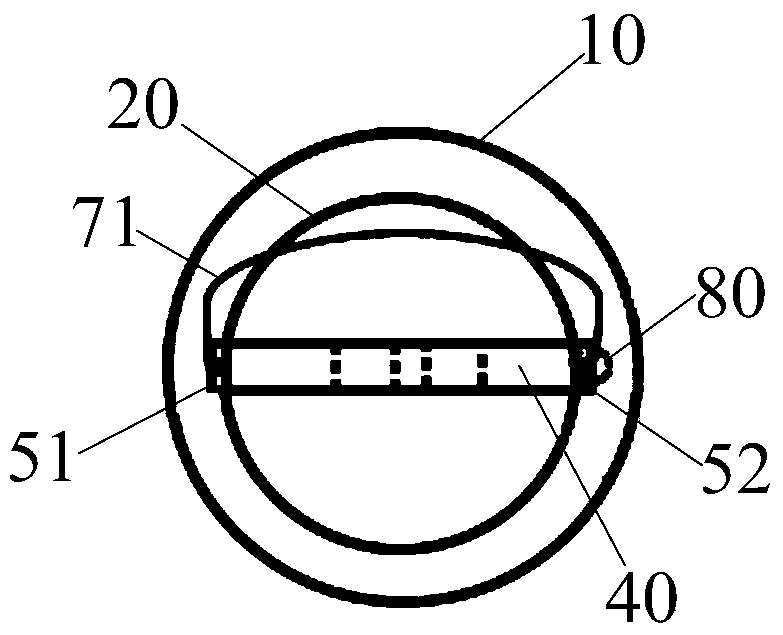

[0050] further, such as Figure 1-2 As shown, the fiber grating pressure sensor includes:

[0051] The pressure chamber 20 communicates with the pressure-tested pipeline, or the pressure-tested pipeline container, or the pressure-tested pipeline equipment;

[0052] The flat diaphragm 30 is fixed on the pressure chamber 20;

[0053] The bracket 40 is fixed on the flat diaphragm 30 and is located at the center of the flat diaphragm 30;

[0054] The first connecting piece 51 and the second connecting piece 52 are symmetrically fixed at the two ends of the support 40; The side of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com