A kind of production method of ultra-thin sa738gr B steel plate

A production method and technology for steel plates, which are applied in the production field of ultra-thin SA738Gr B steel plates, can solve the problems of difficult production, difficult plate shape, and unqualified performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The main elements of the steel plate include C0.15%~0.15%, Si0.2%~0.3%, Mn1.2%~1.5%, Cr≤0.4%, V≤0.015%, and the rest are Fe and unavoidable impurities, including the following step:

[0018] 1) Blanking: the 300mm billet is opened under high temperature and high pressure to a thickness of 100mm, the rolling temperature is 1200°C, 10%≤reduction rate≤25%;

[0019] 2) Rolling: 100mm intermediate billet is heated again, the rolling start temperature must be ≥1000°C, 10%≤reduction rate≤25%;

[0020] 3) Heat treatment: Quenching and tempering is adopted, the quenching and holding temperature is 920°C, the total time in the furnace is 2min / mm, the tempering holding time is 600°C, and the total time in the furnace is 5min / mm;

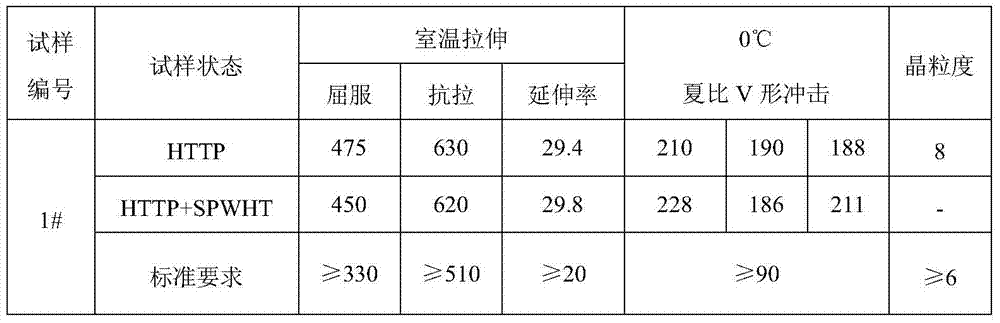

[0021] Through this production method, the SA738Gr B steel plate with the thinnest thickness of 10mm is produced, and the performance of the steel plate also meets the performance standards. The specific performance is as follows:

[0022]

[0023] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com