Connecting mechanism for heightening lathe

A connection mechanism and lathe technology, which is applied to metal processing machinery parts, metal processing equipment, large fixed members, etc., can solve the problems of easy damage, insufficient rigidity and low safety factor of double-column lathes, and achieve safe production and processing, weighing Heavy effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

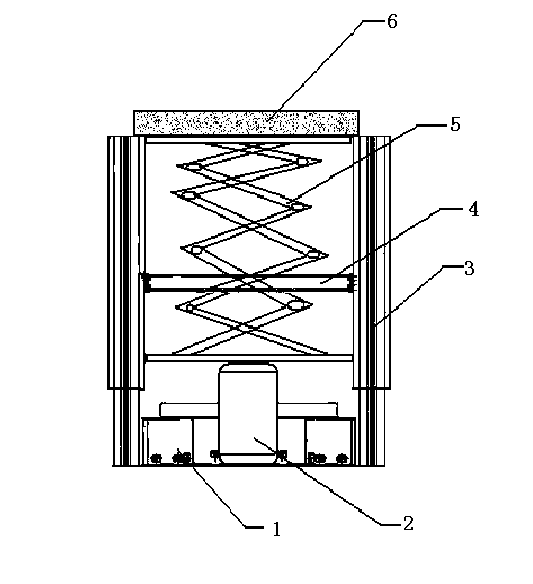

[0013] This embodiment provides a connection mechanism for heightening lathes, which is characterized in that: the connection mechanism for heightening lathes includes a base (1), a driving motor (2), a pillar (3), and a supporting beam (4), lifting device (5), machine tool table (6);

[0014] Among them: the left and right two pillars (3) are fixedly installed at the left and right ends of the base (1), the tops of the left and right two pillars (3) are fixedly installed with the machine tool table (6), and the inner middle positions of the left and right two pillars (3) The support beam (4) is installed, the lower end of the machine tool table (6) is connected to the lifting device (5), and the bottom of the lifting device (5) is connected to the driving motor (2).

[0015] The connection mechanism for raising the lathe according to claim 1, characterized in that: the driving motor (2) is a high-power motor, and the driving motor (2) is fixed at the center of the base (1). ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap