Asymmetric reduction and drawing process for large forgings

An asymmetric and reduction technology, applied in the field of forging, can solve problems such as the limitation of large reduction rate, achieve the effect of reducing the limitation of headroom, avoiding multiple flips, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Taking the high and medium pressure rotor forging of a thermal power steam turbine as an example, the diameter is The upsetting forging with a weight of 66t is drawn into a diameter of Finished forgings.

[0028] The KD method was used for elongation, and both the upper and lower anvils were V-shaped anvils, and the width ratio of the anvils was 0.6.

[0029] Adopt 15000T hydraulic press.

[0030] The elongation process is carried out according to the following steps:

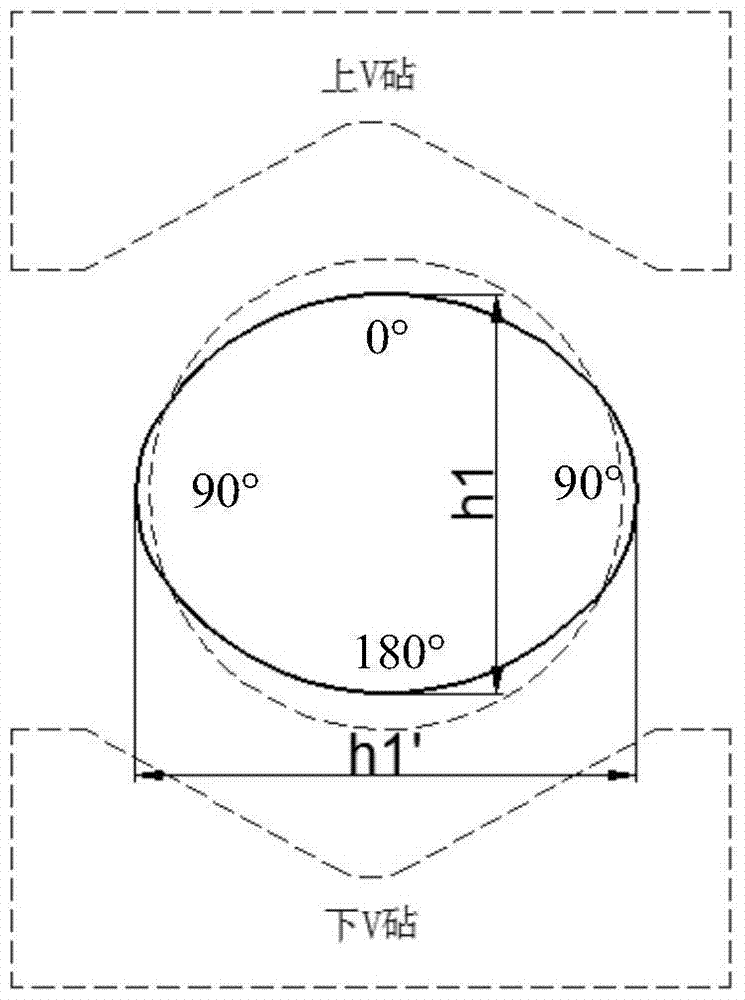

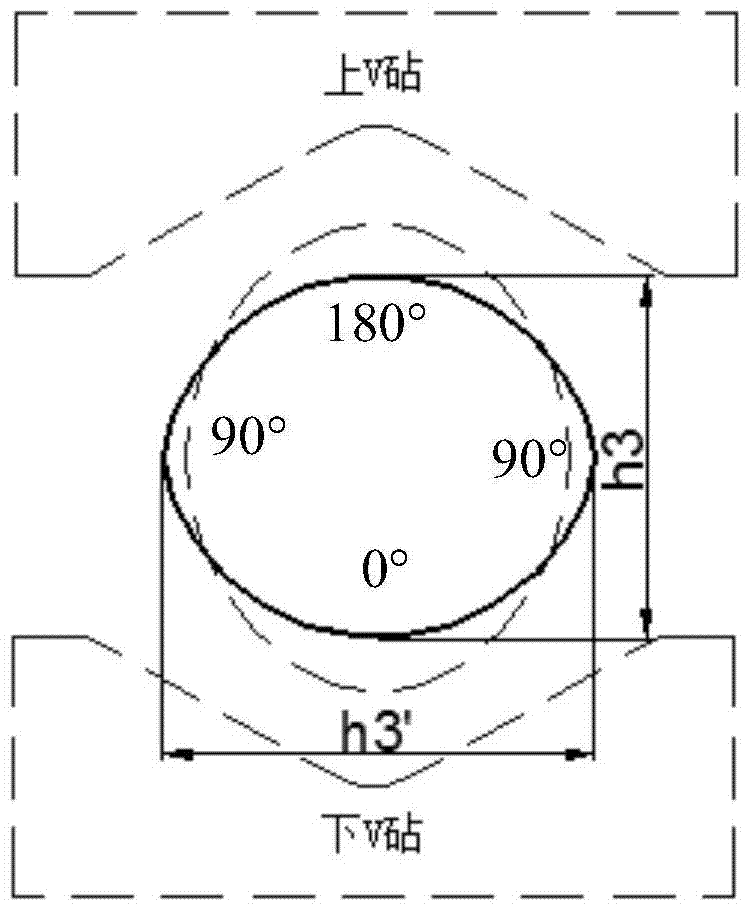

[0031] 1) Put the forgings in accordance with figure 1 Placed in the position shown, the forging is pressed with a small reduction rate in the first pass, and the reduction rate is 15%, and the cross-section of the forging is prefabricated into an ellipse, so as to prevent the forging from being too wide and exceeding the plastic deformation due to the large reduction rate of subsequent multiple passes. scope;

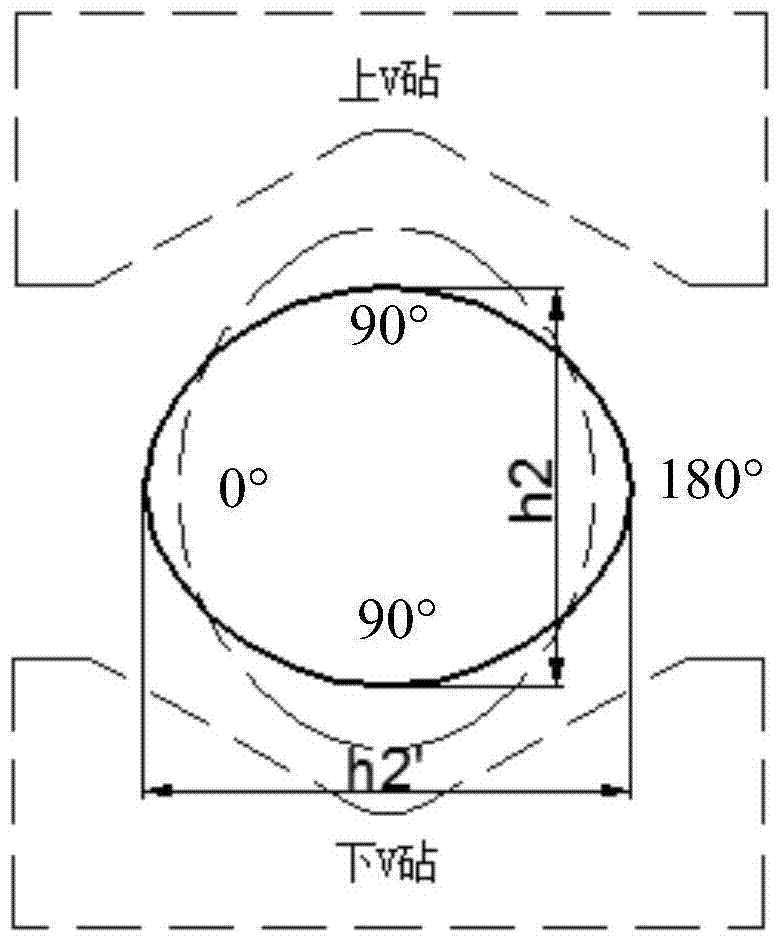

[0032] 2) Turn the forging 90°, such as figure 2 In the position shown, carry out th...

Embodiment 2

[0046] Taking the high and medium pressure rotor forging of a thermal power steam turbine as an example, the diameter is The upsetting forging with a weight of 60t is drawn into a diameter of Finished forgings.

[0047] The KD method was used for elongation, and both the upper and lower anvils were V-shaped anvils, and the width ratio of the anvils was 0.7.

[0048] Adopt 15000T hydraulic press.

[0049] The elongation process is carried out according to the following steps:

[0050] 1) Put the forgings in accordance with figure 1 Placed in the position shown, the forging is pressed with a small reduction rate in the first pass, and the reduction rate is 15%, and the cross-section of the forging is prefabricated into an ellipse, so as to prevent the forging from being too wide and exceeding the plastic deformation due to the large reduction rate of subsequent multiple passes. scope;

[0051] 2) Turn the forging 90°, such as figure 2 In the position shown, carry out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com