A non-cohesive soil sampling device

A sampling device, non-cohesive soil technology, applied in the sampling device and other directions, can solve the problem that the baffle cannot be turned over, and achieve the effect of accurate sampling depth and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

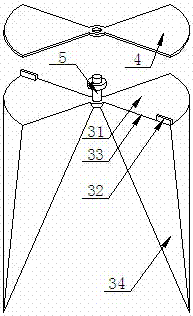

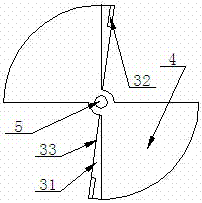

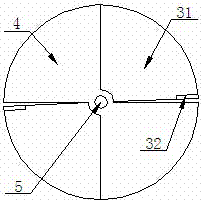

[0025] Such as Figure 1 to Figure 4 As shown, this is a schematic structural diagram of a non-cohesive soil sampling device according to this embodiment.

[0026] The non-cohesive soil sampling device described in this embodiment includes: a cylindrical sampling cylinder, the sampling cylinder includes a sampling top 1 and a sampling bottom 2 that are connected to each other by threads, and the sampling bottom 2 is provided with a fixed The baffle 4 and the movable baffle 3, the fixed baffle 4 is fixedly arranged on the inner wall of the sampling bottom 2, the movable baffle 3 is connected to the fixed baffle 4 through a central rotating shaft 5, and the movable baffle The piece 3 is located below the fixed baffle 4, the central rotating shaft 5 is arranged coaxially with the sampling cylinder, and the top surface of the movable baffle 3 is composed of two fan-shaped plates 31 symmetrical to the central rotating shaft 5 The arcs of the two sector plates 31 are both 90°, the str...

specific Embodiment 2

[0030] Such as Figure 5 As shown, this is a schematic structural diagram of a non-cohesive soil sampling device according to this embodiment.

[0031] In the non-cohesive soil sampling device described in this embodiment, there is one sampling middle part, and the rest of the structure is the same as that in the first embodiment.

[0032] When sampling, first rotate the movable baffle 3 so that the fixed baffle 4 and the movable baffle 3 are in position figure 2 As shown in the state, then by hammering the oblate washer 62 or pressing down the pressurizing handle 61 by manpower, the sampling cylinder is deepened to the sampling depth, while the soil sample entering the sampling cylinder is lifted up. The sampling indication baffle 7 and the limit guide post 71 are moved upward. The analysis and sampling personnel can observe the sampling depth in real time according to the scale on the surface of the limit guide post 71, and stop pressing down the sampling after reaching a predete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com