Complementary type pulp distributing method of headbox

A complementary headbox technology, applied in textiles and papermaking, paper machine, paper machine wet end, etc., can solve the problem of width and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

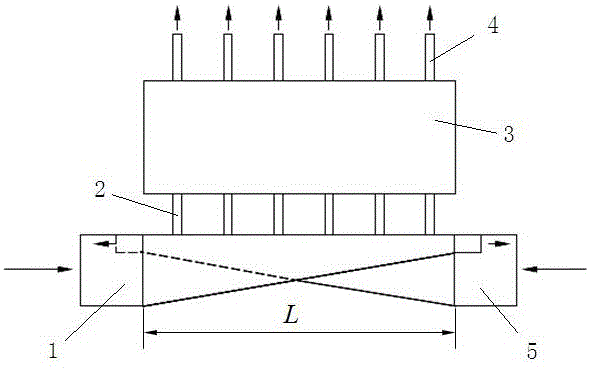

[0021] refer to figure 1 , the complementary type slurry distributing method provided by the present invention, the method comprises:

[0022] a. Provide a complementary slurry distribution device, which is to stack two square cone slurry distribution main pipes (1, 5) with the same structure up and down. The corresponding positions of the slurry distribution main pipes (1, 5) are respectively connected to the mixing chamber through a respective branch pipe 2, and there is a discharge pipe 4 on the mixing chamber 3;

[0023] b. The slurry flows in opposite directions from the inlets of the two square cone slurry main pipes (1, 5), enters the mixing chamber 3 through respective branch pipes for mixing, and is discharged through the discharge pipe 4 after mixing.

[0024] Among the above, the branch pipes on the two square cone cloth slurry main pipes (1, 5) have the same number as the discharge pipes 4 on the mixing chamber 3.

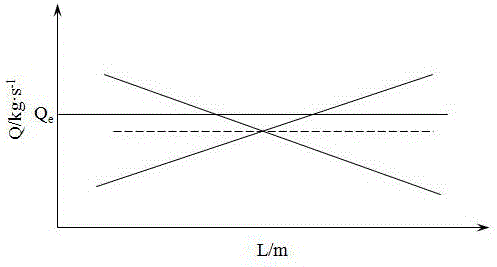

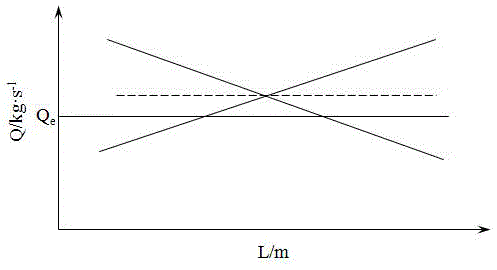

[0025] The mass flow rate of any discharge pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com