A method to improve filling rate

A technology of capping rate and filling slurry, which is applied in the fields of backfill, earthwork drilling, mining equipment, etc., can solve the problems of low filling and topping rate, difficult filling and topping, and difficult to observe the filling situation, so as to achieve the distribution of slurry. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0027] The invention provides a method for improving the filling rate.

[0028] The method includes steps as follows:

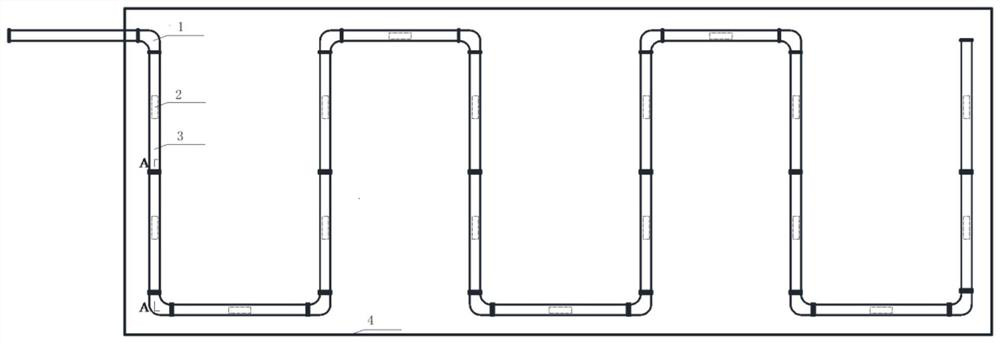

[0029] S1: After the filling and maintenance is completed, the roof conveying pipeline 3 is arranged along the roof in the empty area, and the middle part of the roof conveying pipeline 3 is cut to reserve a gap 2;

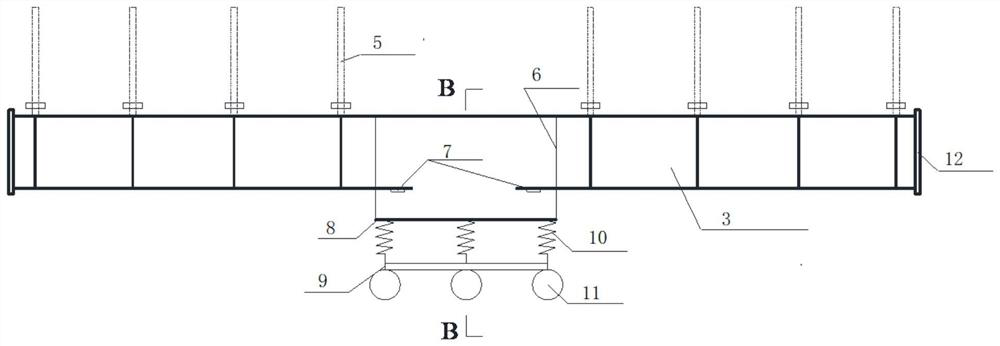

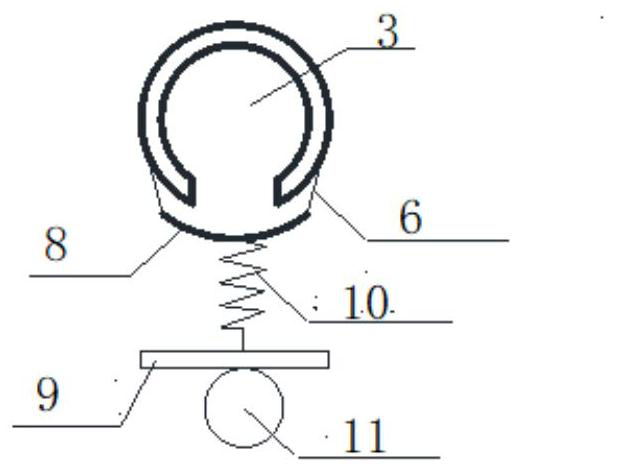

[0030] S2: Assemble the suspension plate 8, spring 10, floating support plate 9 and floating ball 11 to form a floating support device, and suspend the floating support device directly below the reserved gap 2 of the roof conveying pipeline 3 through the sling 6, and the distance from the reserved gap 2200mm~300mm;

[0031] S3: Arrange two miniature pressure boxes 7 symmetrically on both sides of the reserved gap 2 to ens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com