Device for sewing creases of elastic trouser waists and elastic trouser waist sewing method

A trouser waist and elastic technology, which is applied to sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of low precision and high sewing cost of elastic trouser waist and trouser line, and achieve cost saving, avoid positioning difficulties, and facilitate adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

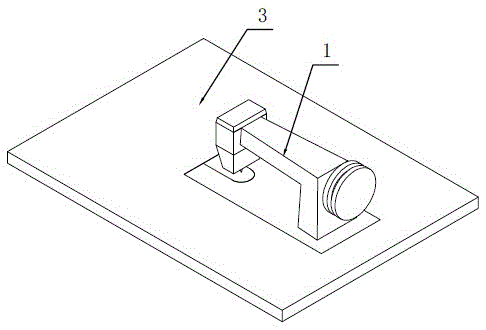

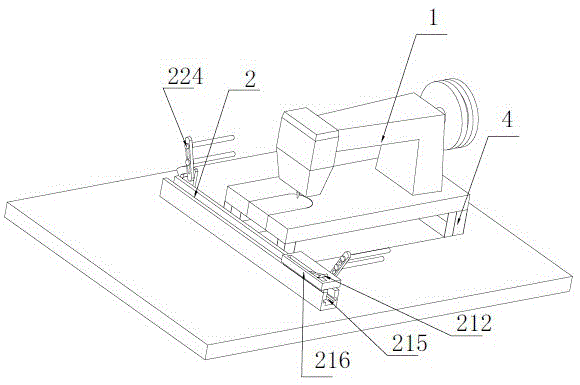

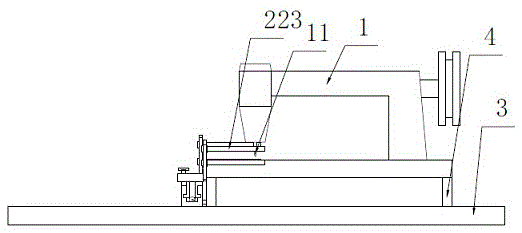

[0040] Embodiment 1: a kind of sewing equipment of elastic trousers waist line, such as Figure 1 to Figure 13 , including a sewing machine 1 and an extension device 2 installed on the panel 3, the extension device 2 includes a positioning mechanism fixed on the panel 3 and an adjustment mechanism for tensioning the elastic waistband, the positioning mechanism includes a guide rail 214, and the adjustment mechanism includes an adjustment mechanism for adjusting the tension of the waistband The length adjustment member E and the position adjustment member F for adjusting the position of the trouser waist are respectively installed on two ends of the guide rail 214 correspondingly.

[0041] The guide rail 214 is provided with a chute 215, and the positioning mechanism also includes a spring 213, a ratchet 212 and a ratchet bar 211 matched therewith. The ratchet bar 211 is installed on the guide rail 214, and the ratchet 212 is fixed on the slide block 216. One end of the spring ...

Embodiment 2

[0047] Embodiment 2: The principle of this embodiment is the same as that of Embodiment 1. The specific difference is that at least two through holes are arranged side by side at one end of the guide rail 214, and the length adjustment member E is installed on the guide rail 214 through the pins in the through holes. , the length adjustment member E is installed at the other end of the guide rail 214 . Change to pin positioning, the pin positioning steps are cumbersome, but the cost is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com