A fully mechanized mining face active magnetized water dedusting atomization nozzle and dedusting method

A technology of atomizing nozzles and magnetized water, which is applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc., can solve the problems of complex rotating structure, dust source coverage, and affecting the movement of cable troughs, so as to achieve reasonable allocation of water volume and reduce dust removal costs , the effect of small surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below.

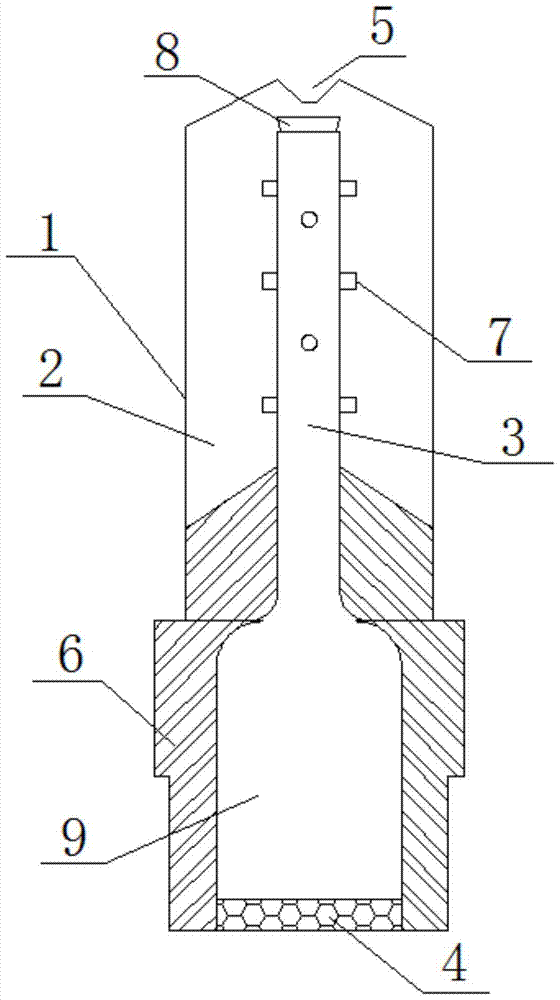

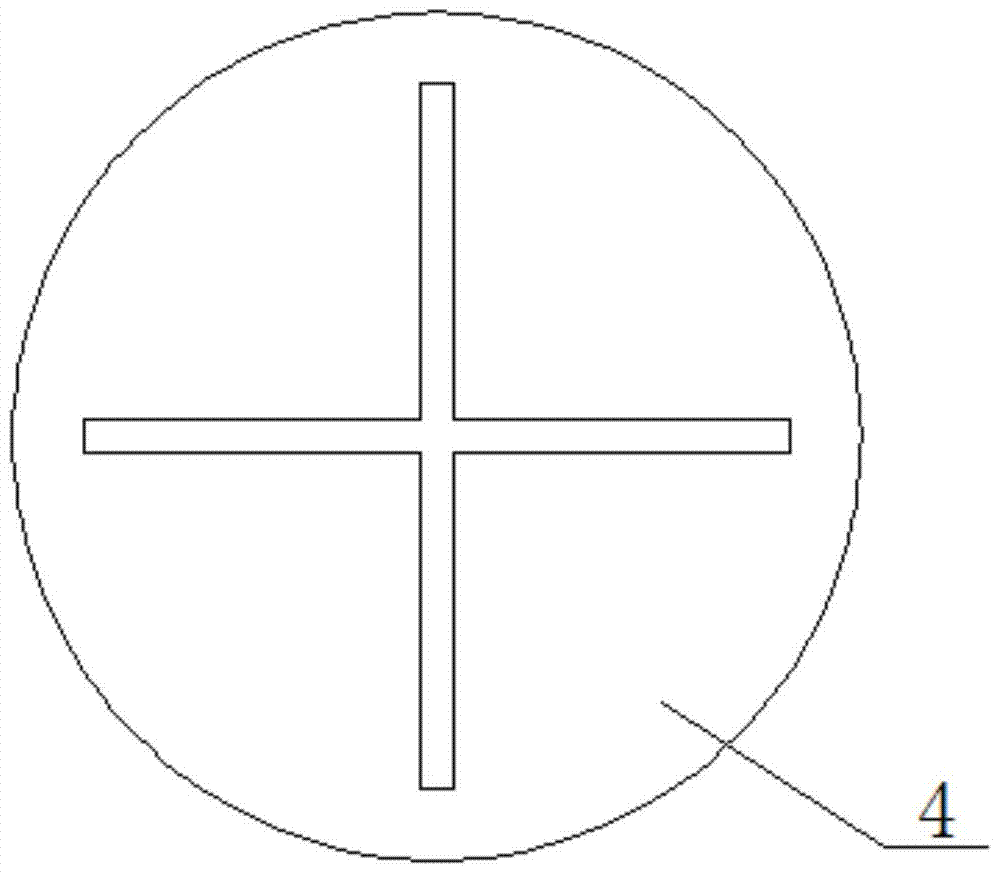

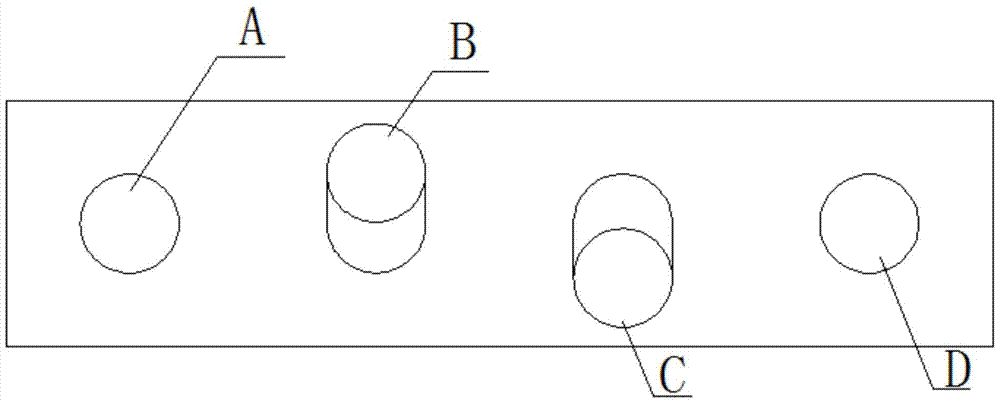

[0022] like figure 1 and figure 2 As shown, the active magnetized water dedusting atomizing nozzle of the fully mechanized mining face includes a nozzle cap 1, an atomizing mixing chamber 2, a spiral water volume regulator 3, a cross gap diaphragm 4, a spray hole 5, a nozzle base 6, and a water outlet hole 7 and the nozzle inner cavity 9, the lower end of the nozzle base 6 is connected to the nozzle arranger through threads, the nozzle base 6 is provided with a nozzle inner cavity 9, the nozzle cap 1 is mounted on the nozzle base 6 through threads, and the spray hole 5 is arranged on the top of the nozzle cap 1, and the spiral water regulator 3 is arranged in the nozzle cap 1, and the spiral water regulator 3 is connected with the inner chamber of the nozzle 9 by a streamline transition, and the top of the spiral water regulator 3 An adjusting nut 8 is provided, the water outlet hole 7 is arranged on the side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com