Safe beehive for pollination

A beehive and safe technology, applied in the field of safe beehives for pollination, can solve the problems of long manufacturing cycle, perishable wooden beehives, heavy weight, etc., and achieve the effects of high mechanical strength, good thermal insulation and anti-corrosion performance, and reasonable size and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

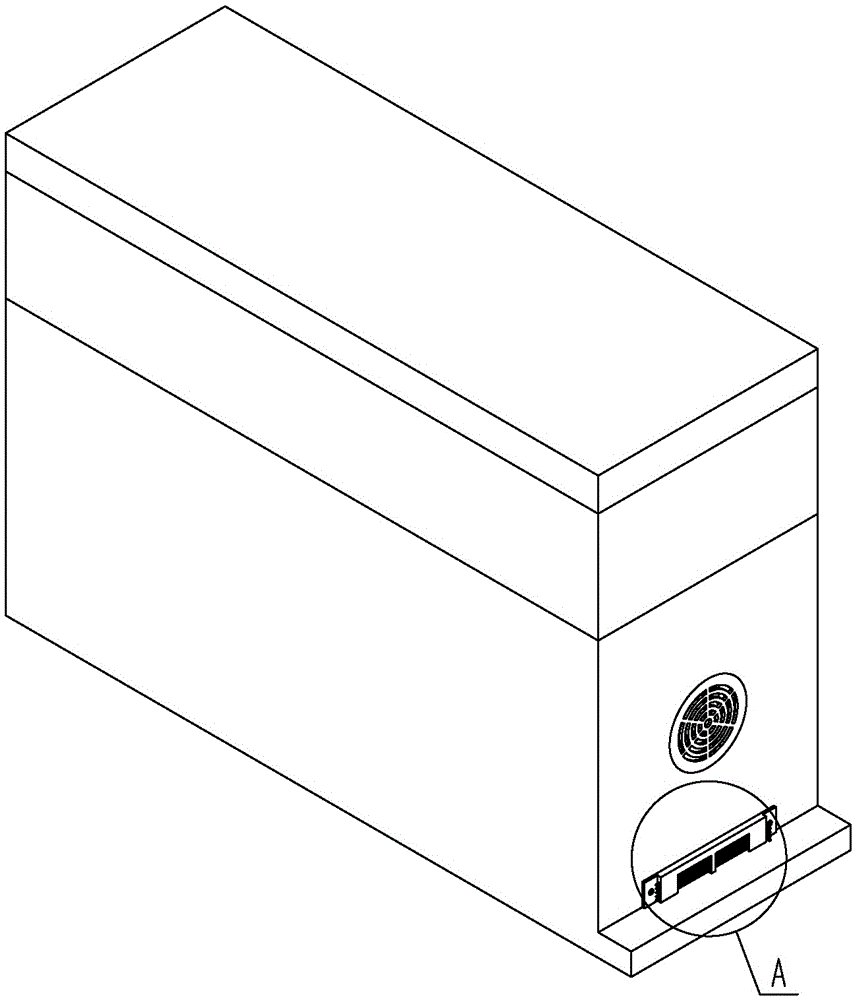

[0040] Such as Figures 1 to 6 As shown, a safety beehive for pollination includes a cover 1 , a second box 2 and a first box 3 assembled sequentially from top to bottom. The second box body 2 both can take fully open type setting so that clean up, also can take to perforate in top plate 18 and only be used for adding liquid feed. The assembly between the case cover 1, the second case body 2 and the first case body 3 can adopt a protrusion 14 or a groove structure on the assembly surface to meet the assembly stability requirements.

[0041] The side wall of the first casing 3 offers a nest mouth 8, and a nest door is horizontally arranged at the nest mouth place, and the nest door includes a door frame 22 and some cutting strips 24, and the both sides of the door frame 22 offer some first through holes, and the cutting strips 24 The activity is assembled in the first through hole so as to control the entry and exit of the bee colony. The gap width between two adjacent cuttin...

Embodiment 2

[0055] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the shield 4 has two vertical plates 15 and a horizontal plate 16 connecting the two vertical plates 15, and the two vertical plates 15 are perpendicular to the bottom of the second box body 2. The bottom plate 20 thus constitutes a U-shaped structure.

Embodiment 3

[0057] Such as Figure 8 As shown, the difference between the present embodiment and the second embodiment lies in that the upper ends of the two vertical plates 15 are inclined supercenter to form a V-shaped structure, and correspondingly, the shape of the cavity is also V-shaped.

[0058] The number of eating chambers can be two, and they are symmetrically arranged in the second casing 2, so that when liquid feed 11 is added to the second casing 2, the liquid feed 11 will flow to the eating chambers on both sides so that Bees spread out more when feeding to avoid crowding. The structure of the eating room is not limited to the specific structure in the foregoing embodiments, and relevant parts of the second box can be rationally used to form a cavity that meets the requirements to achieve the purpose of the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com