Automatic cycle startup and shutdown control method and device

A technology of on-off control and automatic cycle, applied in general control system, control/regulation system, adaptive control, etc., can solve the problems of energy waste, non-energy saving, error or misoperation, etc., to avoid energy waste and ensure operation life, to achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

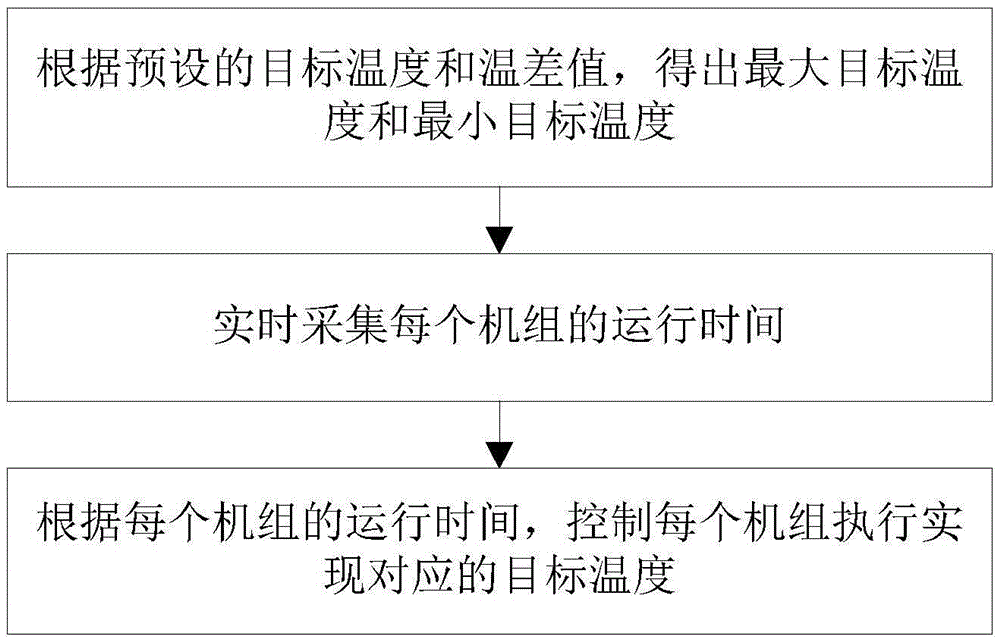

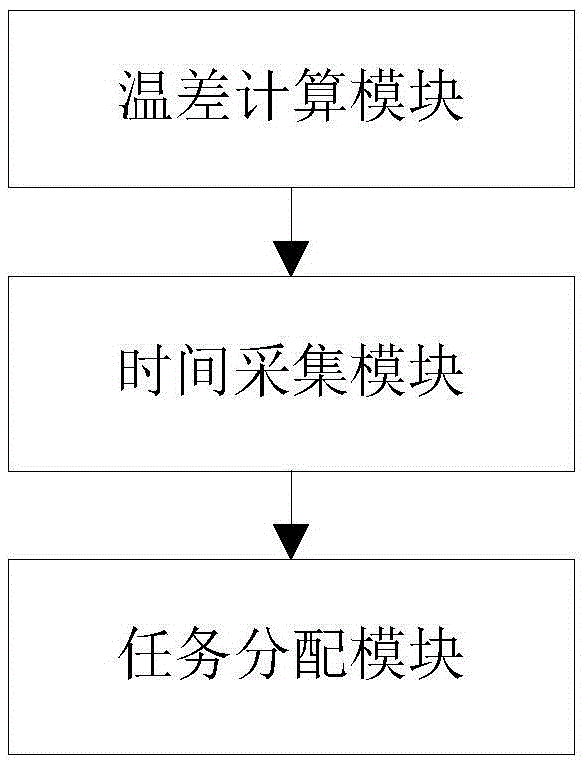

[0039] refer to figure 1 , the present invention a kind of automatic circulation switching machine control method, comprises the following steps:

[0040] According to the preset target temperature and temperature difference value, the maximum target temperature and the minimum target temperature are obtained;

[0041] Collect the running time of each unit in real time;

[0042] According to the running time of each unit, each unit is controlled to achieve the corresponding target temperature.

[0043] Further as a preferred implementation, the said control of each unit to implement the corresponding target temperature according to the running time of each unit includes:

[0044] Control the execution of multiple units with the shortest running time to achieve the maximum target temperature;

[0045] Control the execution of multiple units with the longest running time to achieve the minimum target temperature;

[0046] Control the remaining multiple units to execute to ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com