Control method of compressor unit

A technology of compressor unit and control method, which is applied to refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as affecting the reliability of unit operation, compressor start and stop, and inability to balance compressor operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

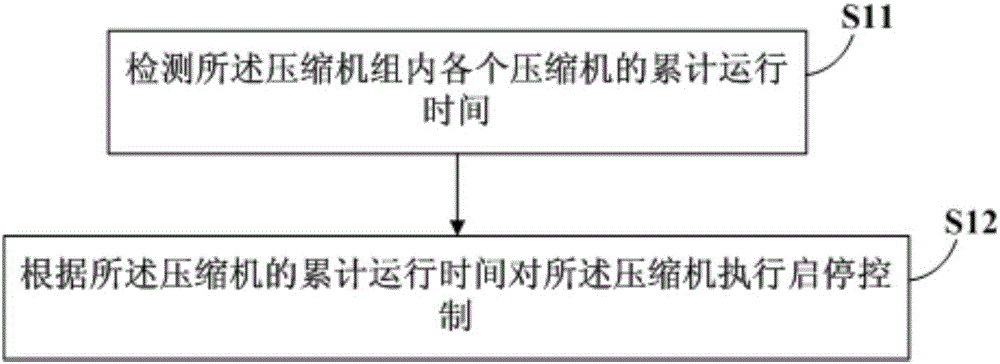

[0018] This embodiment provides a technical solution of the control method of the compressor unit. In this technical solution, the control method of the compressor group includes: detecting the running time of each compressor in the compressor group; and performing start-stop control on the compressor according to the running time of the compressor.

[0019] see figure 1 , the control method of the compressor unit includes:

[0020] S11. Detect the cumulative running time of each compressor in the compressor group.

[0021] In this embodiment, a central processor is provided for the compressor group, and the accumulated running time of each compressor in the compressor group is detected by this central processor. The accumulative running time is the accumulative running time of each compressor in the compressor group when it is turned on, and the accumulative running time is generally not cleared. Only when the entirety of the compressor set stops running, the accumulated r...

no. 2 example

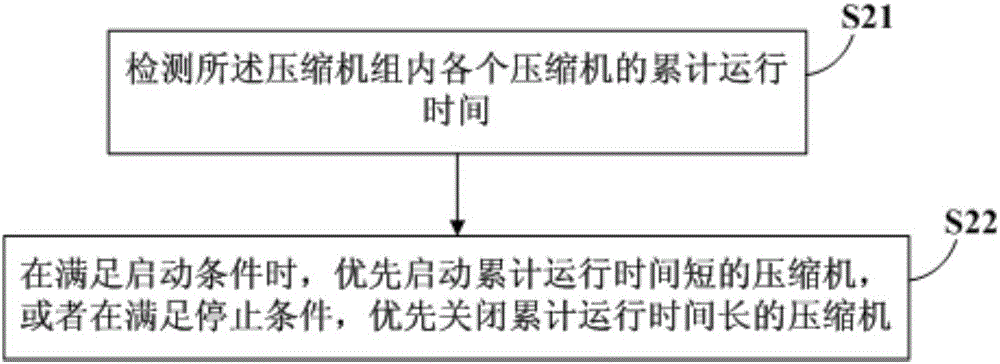

[0038] Based on the above-mentioned embodiments of the present invention, this embodiment further provides a technical solution of a control method for a compressor unit. In this technical solution, performing start-stop control on the compressor according to the accumulative running time of the compressor includes: when the start-up condition is met, the compressor with the shortest accumulative run-time is preferentially started; or when the stop condition is met, priority is given to Turn off compressors that have accumulated a long running time. Further, performing the start-stop control on the compressor according to the accumulated running time of the compressors further includes: when the start-up condition is met, if the accumulated running time of at least two compressors is the same, preferentially start the compressor whose name is ranked first or when the stop condition is met, if at least two compressors have the same cumulative running time, the compressor whose ...

no. 3 example

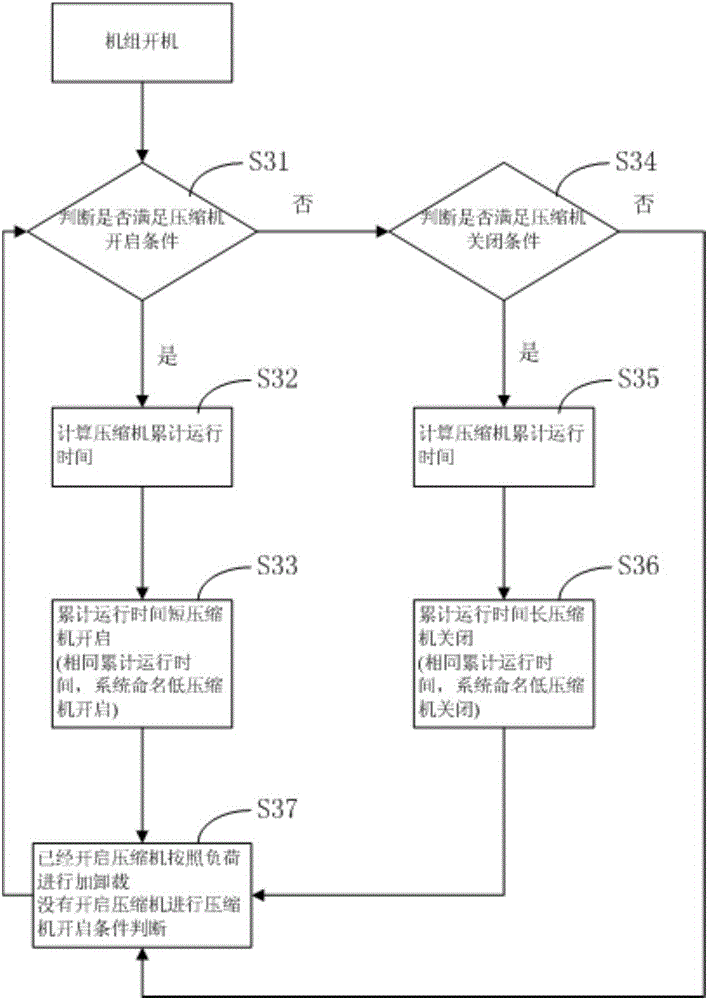

[0046] This embodiment provides a technical solution of the control method of the compressor unit. see image 3 , the control method of the compressor unit includes:

[0047] S31, judging whether the condition for turning on the compressor is satisfied, if yes, execute S32, if not, execute S34.

[0048] S32. Calculate the accumulative running time of the compressor.

[0049] S33, the compressor with the shortest accumulated running time is turned on.

[0050] At this time, if the accumulative running time of the two compressors is the same, the compressor with the lowest name in the system, that is, the compressor whose name is ranked first will be turned on first.

[0051] S34, judging whether the condition for shutting down the compressor is satisfied, if yes, execute S25, and if not, execute S27.

[0052] S35, calculating the accumulative running time of the compressor.

[0053] S36, the compressor with a long accumulative running time is turned on.

[0054] At this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com