Portable outline detection device for train wheel tread

A wheel tread and profile detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as distortion, low measurement accuracy, and reduce the requirements for sensor measurement range, and achieve strong integrity, compact instrument structure, and device compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

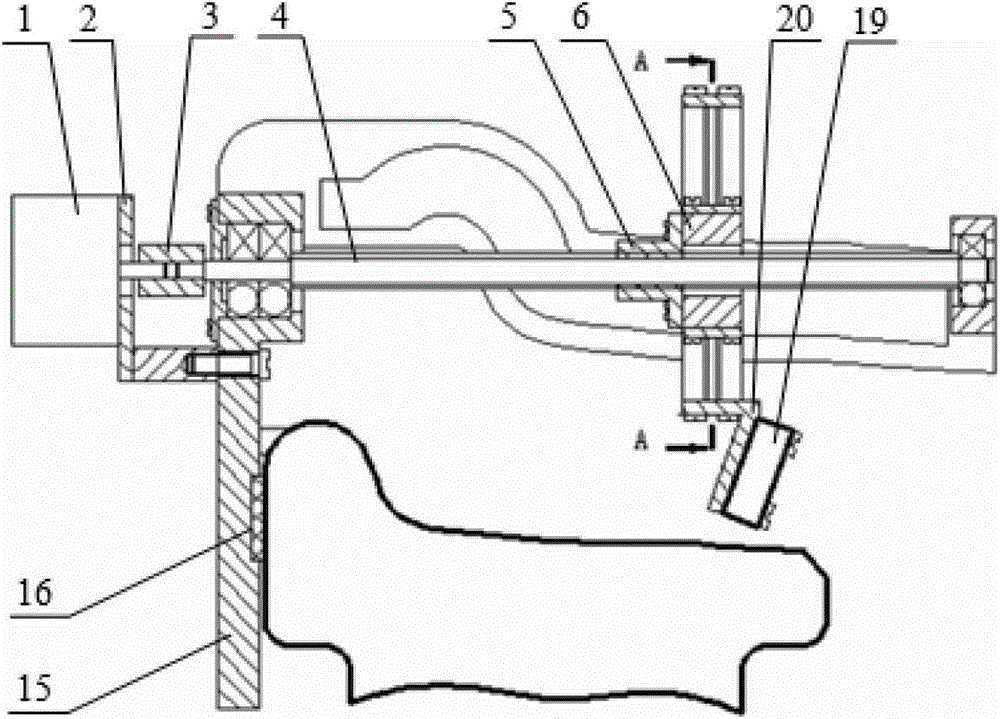

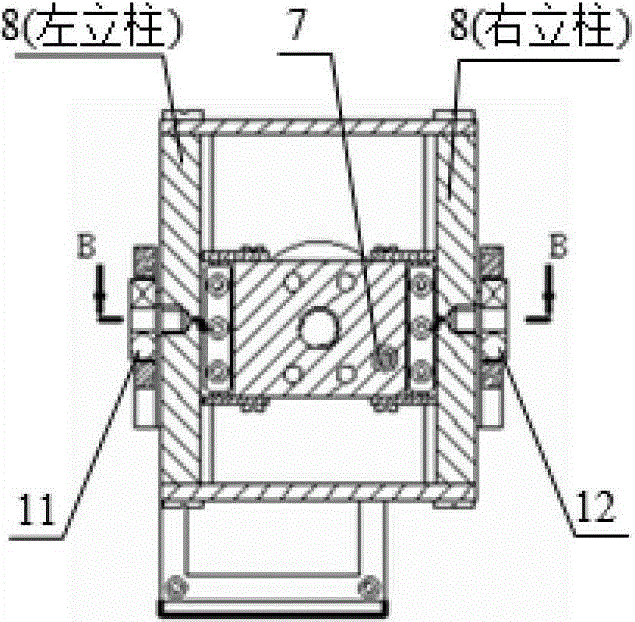

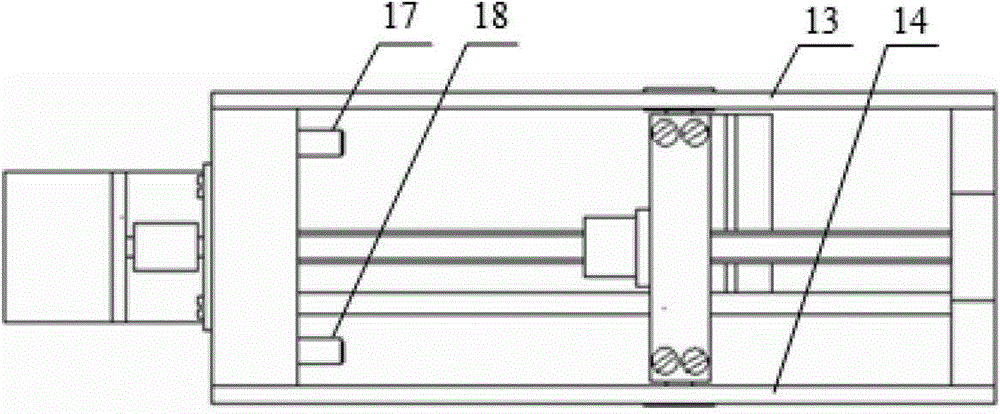

[0028] Further illustrate the present invention below in conjunction with accompanying drawing.

[0029] Such as Figure 1 to Figure 4 As shown, the stepper motor 1 is installed on the support base 2, and drives the screw 4 through the coupling 3; the nut 5 is fixedly connected with the slider 6, and the light hole on the slider 6 is slidably matched with the stop guide rod 7 , the limit nut can only move in a straight line; V-shaped ball guide rails 9 and 10 are installed between the two sides of the slider 6 and the inner sides of the left and right columns of the sensor mounting frame 8, so that the mounting frame 8 can move up and down; the left and right columns of the mounting frame 8 Bearings 11 and 12 are respectively housed on the outer surfaces; the two bearings roll along profiling guide rails 13 and 14 respectively. When the slider 6 (connected with the nut 5) moves linearly, the force is transmitted to the sensor mounting frame 8 through the V-shaped ball guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com