Enlarged type elastic coupling for metal diaphragm

A technology of elastic couplings and metal diaphragms, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problems of large deviation and the incomplete compensation of metal diaphragm elastic couplings, and achieve the compensation effect Good, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

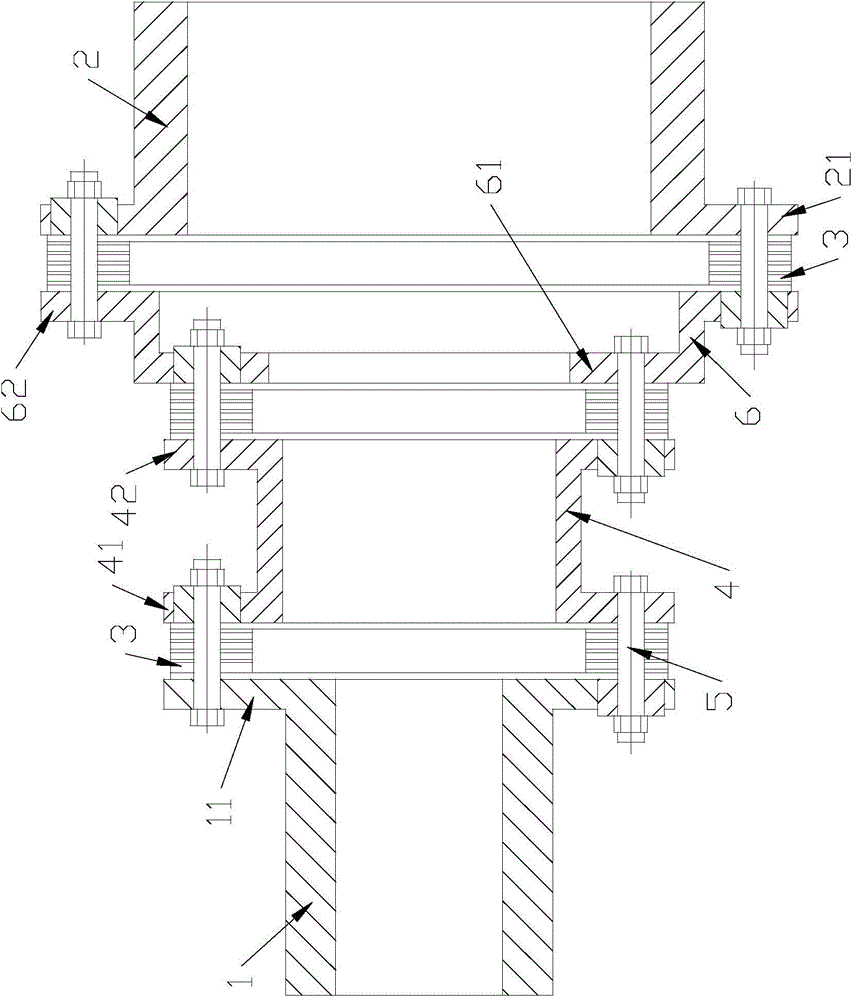

[0010] figure 1 The enlarged metal diaphragm elastic coupling shown includes an input shaft 1 with a flange 11 at one end, an output shaft 2 with a flange 21 at one end, a metal diaphragm assembly 3, and left and right ends with The first intermediate shaft 4 of the flanges 41, 42, and the second intermediate shaft 6 with flanges 61, 62 at the left and right ends respectively. The input shaft 1, the first intermediate shaft 4, the second intermediate shaft 6, and the output shaft 2 are all hollow shafts. The inner diameters of the shaft holes of the input shaft, the first intermediate shaft, and the second intermediate shaft increase sequentially, and the shaft holes of the output shaft The inner diameter is larger than the shaft bore inner diameter of the input shaft.

[0011] The flange 11 , the flange 41 and the metal diaphragm assembly 3 between the flange 11 and the flange 41 are connected by bolts 5 . The flange 41 , the flange 61 and the metal diaphragm assembly 3 bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com