Underground bicycle garage with laser spacing function

A bicycle garage and bicycle technology, applied in the field of underground bicycle garages, can solve the problems of a lot of time, high cost, difficult installation, etc., and achieve the effects of saving ground space, high support strength, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

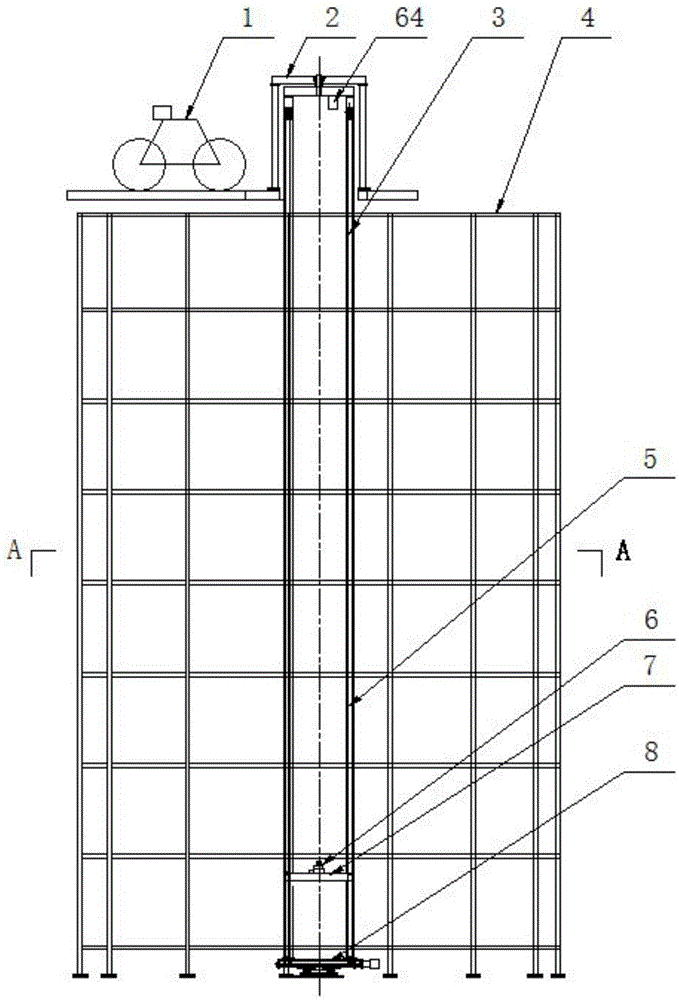

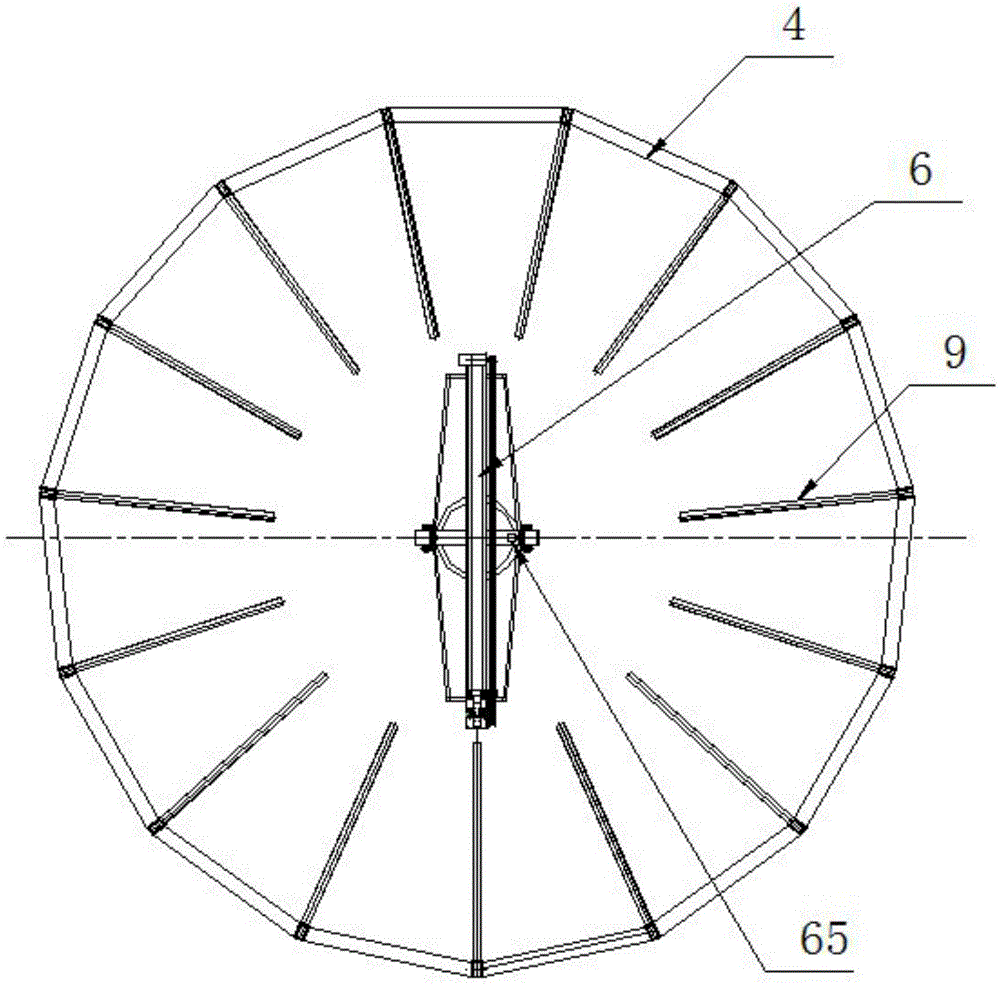

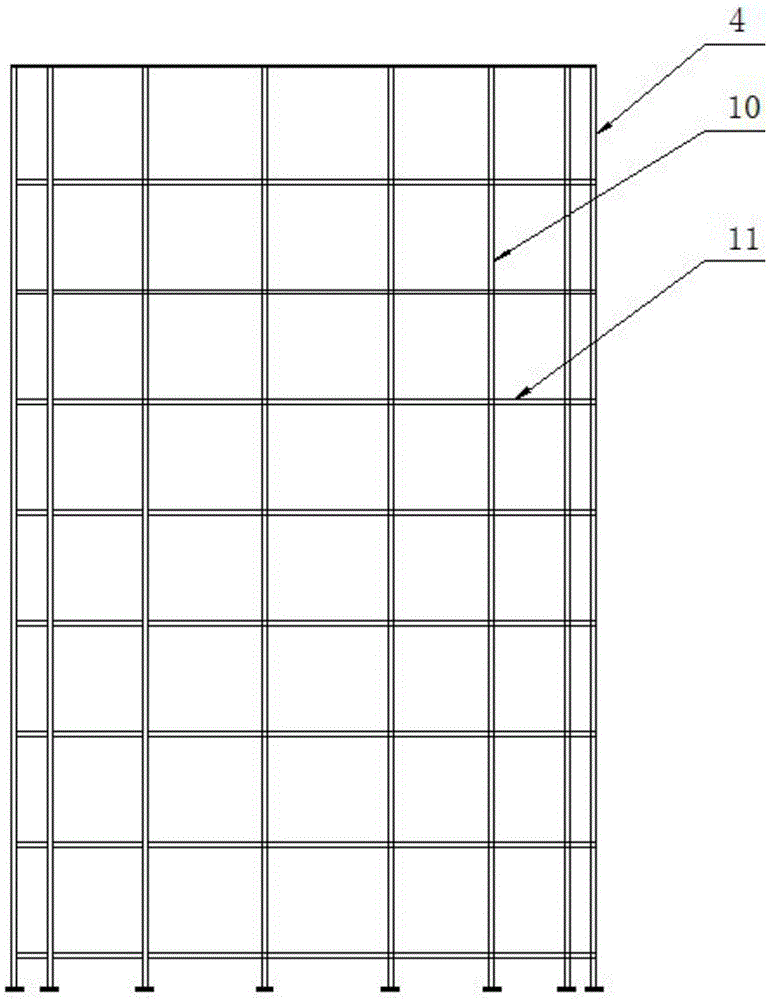

[0044] An underground bicycle garage with laser distance measurement function, which is composed of an assembled support unit and a central conveying unit. The assembled support unit is composed of a cage-type cylinder 4 and a multi-layer circumferentially arranged on the inner wall of the cage-type cylinder toward the axis position. A bicycle storage rack 9 is formed; the central conveying unit is installed at the axial position of the assembled support unit. The central conveying unit consists of a parallel rotating guide rail 3, a synchronous belt type lifting mechanism 5, a shaft supporting type rotating mechanism 8 and a conveying table. 7 structure, a synchronous belt lifting mechanism is set on the rotating guide rail, the conveying table is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com