Clean technology for continuously synthesizing 2,4-dinitro-6-chloroaniline

A technology of dinitroaniline and dinitro, which is applied in the field of cleaning technology for synthesizing 2,4-dinitro-6-chloroaniline, can solve problems such as unclean production and difficult treatment, achieves reduction of the amount of hydrochloric acid, avoidance of Effects of exhaust emissions, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

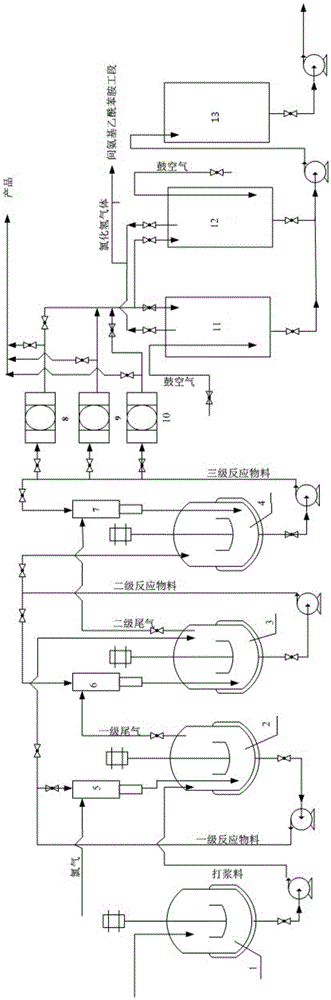

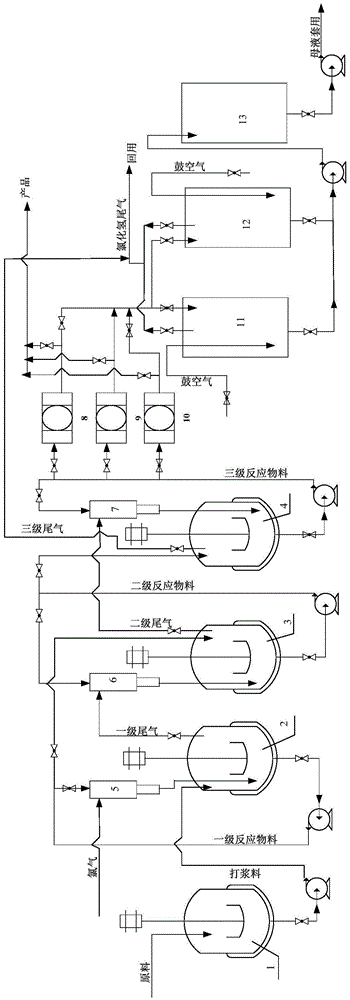

[0032] Continuous synthesis:

[0033] Such as figure 1 , using three-stage series reactors (2, 3, 4), three parallel filter presses (8, 9, 10) and two parallel mother liquor recovery tanks (11, 12), the first, second, and third stages The volume of the reactor is 50m 3 , control the chlorination temperature at 35-40°C, and the volume of the mother liquor recovery tank is 50m 3 , the volume of the filter press is 500m 3 , the volume of the mother liquor storage tank is 100m 3 , The liquid level of the mother liquid recovery tank is set to 90% of the volume.

[0034]Into the beating kettle (1), feed raw materials simultaneously and continuously for beating, control the feed rate of 2,4-dinitroaniline to be 915kg / h, the feed rate of 31% hydrochloric acid to be 4502kg / h, and 38% dispersant The feed rate of MF is 24kg / h, and the material in the beating tank enters the first-stage reactor (1) at a speed of 5441kg / h; the chlorine gas is passed into the first-stage reactor throug...

Embodiment 2

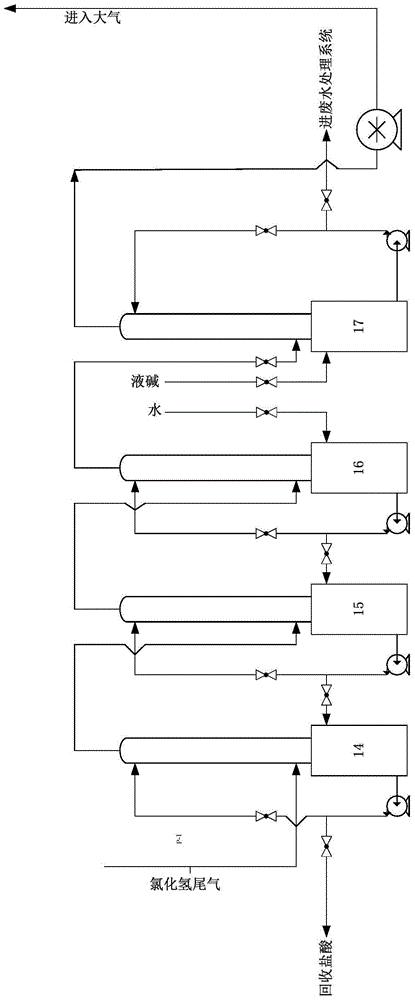

[0039] According to the operation method described in Example 1, only the hydrochloric acid is replaced with the mother liquor in the mother liquor storage tank, and the filter cake from the filter press is washed and dried to obtain the 2,4-dinitro-6 -Chloroaniline, measured purity (HPLC) 98.2%, yield 96.8%. The collected HCl gas is used for the synthesis of m-acetaniline, and the purity (HPLC) of 99% m-acetaniline can be obtained.

Embodiment 3

[0041] Continuous synthesis:

[0042] According to the operating method described in Example 1, the difference is the flow rate of raw materials: the feed rate of 2,4-dinitroaniline is 732kg / h, the feed rate of 30% hydrochloric acid is 3893kg / h, and 38% dispersion The feed rate of agent MF is 20kg / h, and the material in the beating kettle enters the first-stage reaction kettle at a speed of 4918kg / h; The material in the reaction kettle is passed into the next-stage reaction kettle at a flow rate of 5191kg / h; then injected into the filter press for filtration at a flow rate of 5191kg / h, and the filter press also enters the mother liquor recovery tank at a flow rate of 5191kg / h; the mother liquor recovery tank The air is blown in the middle, and when the concentration of hydrochloric acid is 30%, the air blowing is stopped, and the mother liquor enters the mother liquor storage tank, and the hydrogen chloride tail gas is collected at the same time; the mother liquor in the mothe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com