Ammonia gas absorption device

A technology of absorption device and tail gas absorption tower, which is applied in gas treatment, dispersed particle separation, membrane technology and other directions, can solve problems such as affecting the dissolution and recovery of ammonia gas, causing pollution to the environment, and difficult to fill fog droplets, etc., to achieve great social benefits, The effect of low operating cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

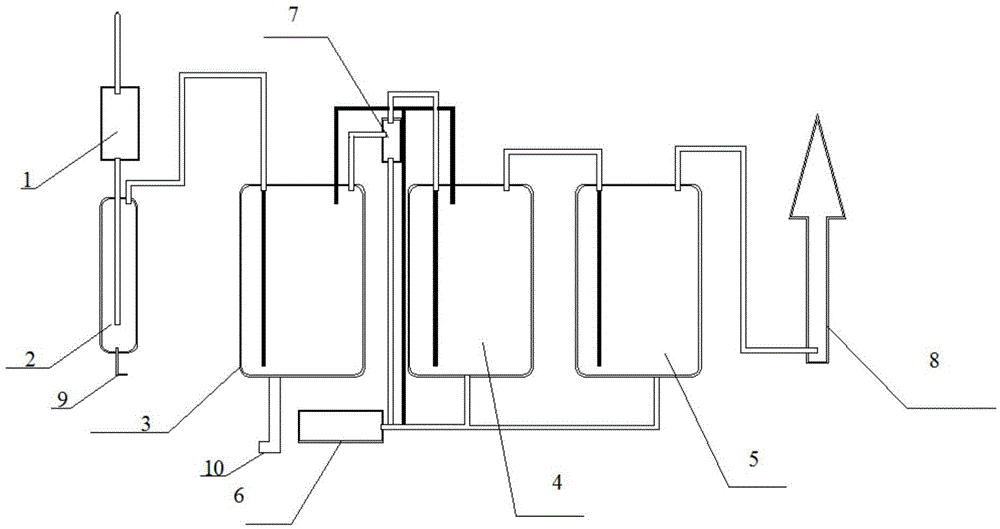

[0018] like figure 1 Shown, a kind of ammonia absorption device comprises condenser 1, buffer tank 2, primary absorption tank 3, secondary absorption tank 4, tertiary absorption tank 5 and tail gas absorption tower 8; condenser 1, buffer tank 2, The first-level absorption tank 3, the second-level absorption tank 4, the third-level absorption tank 5 and the tail gas absorption tower 8 are connected in sequence through gas pipelines; Wrapped with an insulating layer, there are cooling devices inside the primary absorption tank 3 and the secondary absorption tank 4 .

[0019] The above-mentioned primary absorption tank 3, secondary absorption tank 4 and tertiary absorption ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com