Shallow-tillage weeding machine

A weeding machine and frame technology, which is applied in the fields of soil preparation machinery, weed eradication equipment, agricultural machinery and implements, etc., can solve the problems of high cost, large amount of ground breaking, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

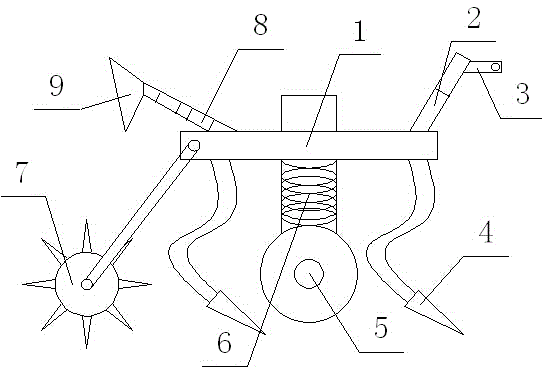

[0010] Example: such as figure 1 As shown, a shallow pine weeder includes a frame body 1, the upper part of the frame body 1 is provided with a telescopic rod 2, the telescopic rod 2 is provided with a suspension device 3, and the bottom of the frame body 1 is provided with two rows of shallow Loosen the shovel 4, and the center of the bottom of the frame body 1 is also provided with a road wheel 5, the road wheel 5 is connected with the frame body 1 through a damping spring 6, and the rear part of the frame body 1 is equipped with a weeding roller 7 through a connecting rod, The surface of the weeding roller 7 is provided with evenly distributed protrusions, and the frame body 1 is also provided with a universal tube 8, and the other end of the universal tube 8 is connected with a lighting device 9; The frame body 1 is clamped.

[0011] The present invention is simple in structure, convenient and practical, is provided with suspension device 3, is convenient to be connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com