Formwork panel for concreting formworks

A technology of concrete and formwork, applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problem of short life of the formwork skin and achieve good positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] In the following description of the embodiments of the present invention, for brevity, the term "formwork panel" is used instead of "formwork panel for concrete construction backboard". All formwork panels shown and described in terms of their size and load capacity are designed to withstand the loads that occur during the use of concrete construction backs.

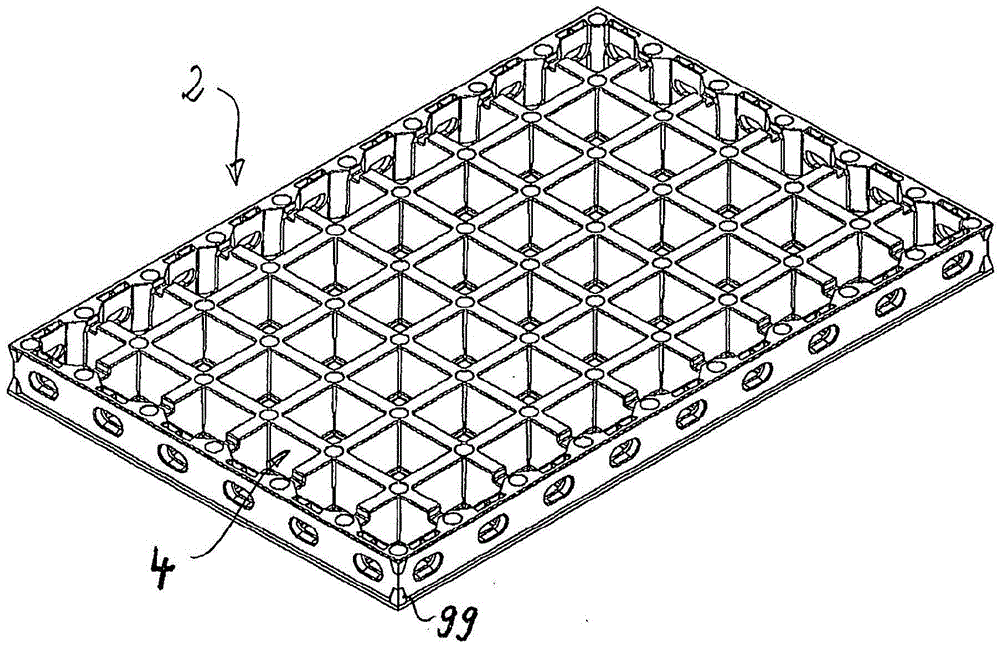

[0106] Figure 1 to Figure 8 The formwork panel 2 shown in is composed of two component parts, namely the support structure 4 and the formwork skin 6, wherein, in the exemplary case, the formwork skin 6 is composed of a single formwork skin element 8. The supporting structure 4 and the template skin element 8 in the example case are all made of plastic material.

[0107] In general, the template panel has the shape or geometric structure of a regular hexahedron, in which, as with figure 1 The plane of the front side 10 of the template skin seen in the, is measured at right angles and the front side 10 of the template ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com