Method for detecting emulsion paint film and smell in construction

A latex paint and odor technology, which is applied in the field of paint film odor detection, can solve the problems of few samples, the inability to intuitively reflect the size of the odor, and the lack of objective judgment basis, so as to achieve objective and fair evaluation, easy promotion, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

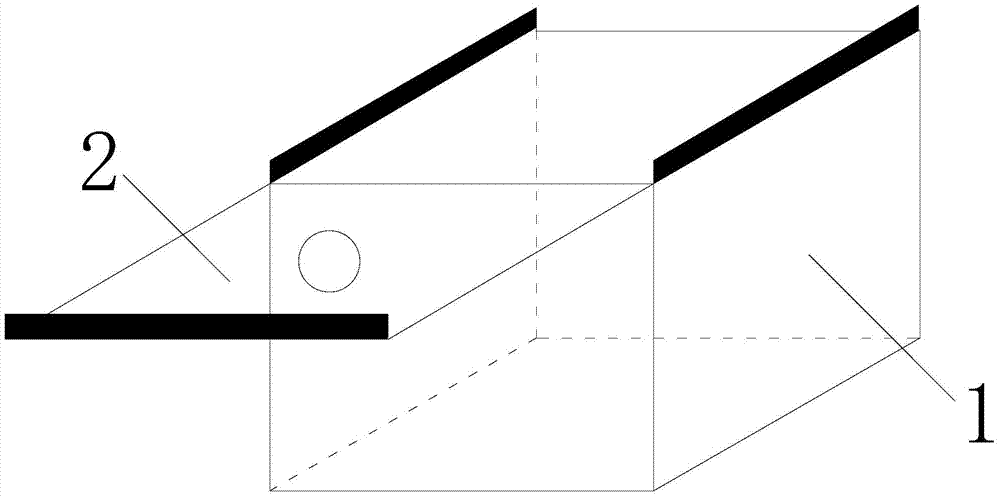

[0038] The present invention is described in detail below in conjunction with accompanying drawing description:

[0039] The present invention comprises the steps:

[0040] Step 1: Wash and dry the odor measurement chamber and glass plate with distilled water for later use;

[0041] Step 2: Test the smell of roller coating construction: use a wire rod to evenly smear the test sample on the glass plate for plate making, then put the glass plate into the odor measurement cabin and close the cabin door 2; leave it for 1h, and then open the cabin door 2 , test with an odor tester, the smell tester should be 10cm away from the glass plate, record the highest value of the reading within 1min, test 3 times continuously, and take the average value of each group of data;

[0042] Step 3: Paint film odor test: fully open the door 2 of the odor measurement cabin, so that the inside of the odor measurement cabin 1 is completely connected to the test environment outside the cabin 1 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com