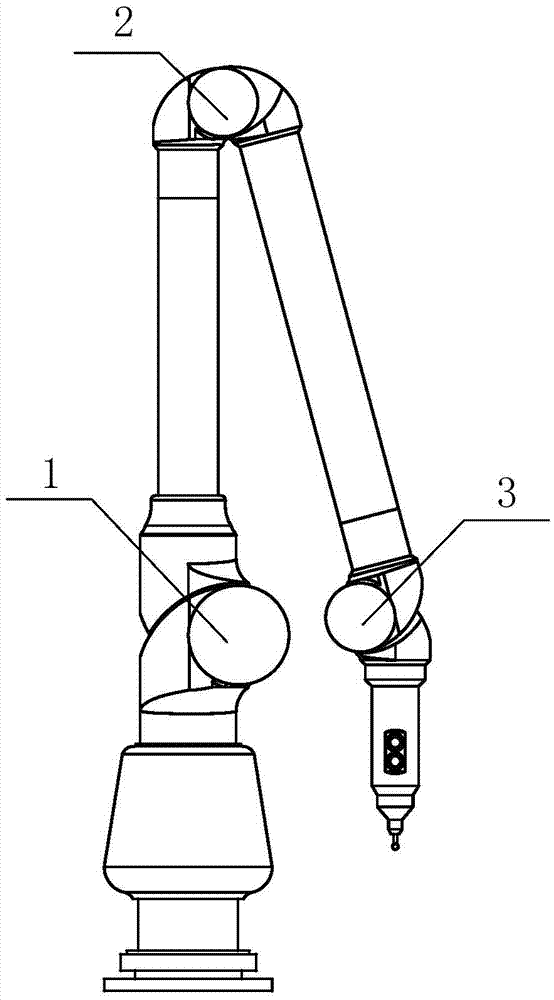

Swing joint for realizing force balance and mechanism limit by using internal bending springs

A technology for bending springs and realizing force, applied in springs/shock absorbers, measuring devices, mechanical equipment, etc., to achieve the effect of improving work adaptability, reducing occupied space, and reducing measurement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

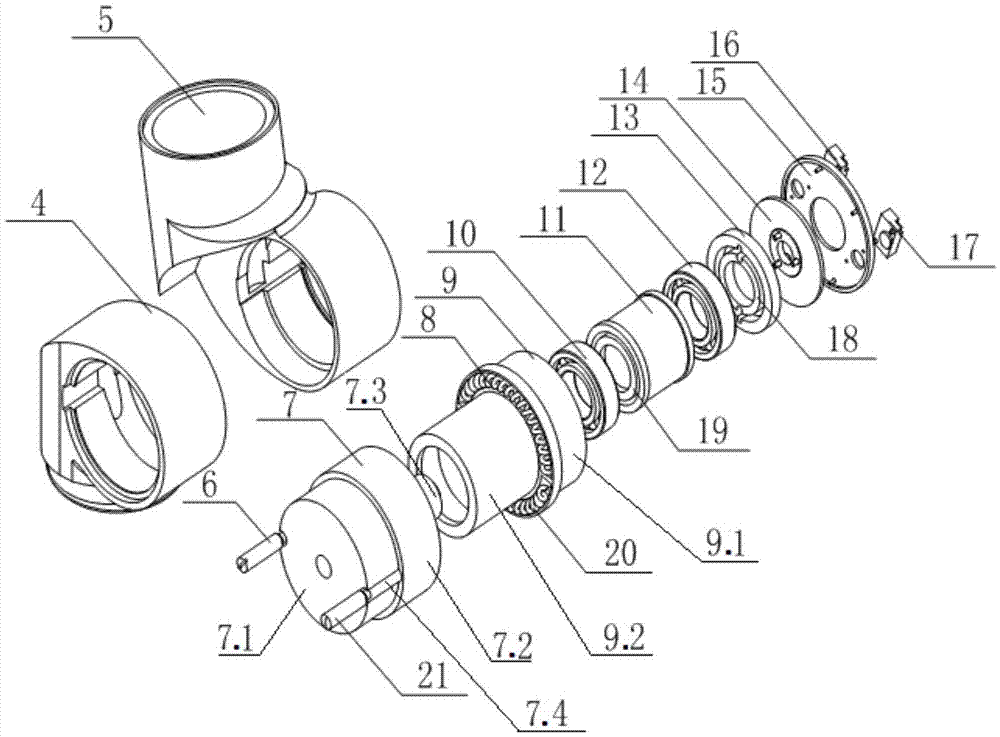

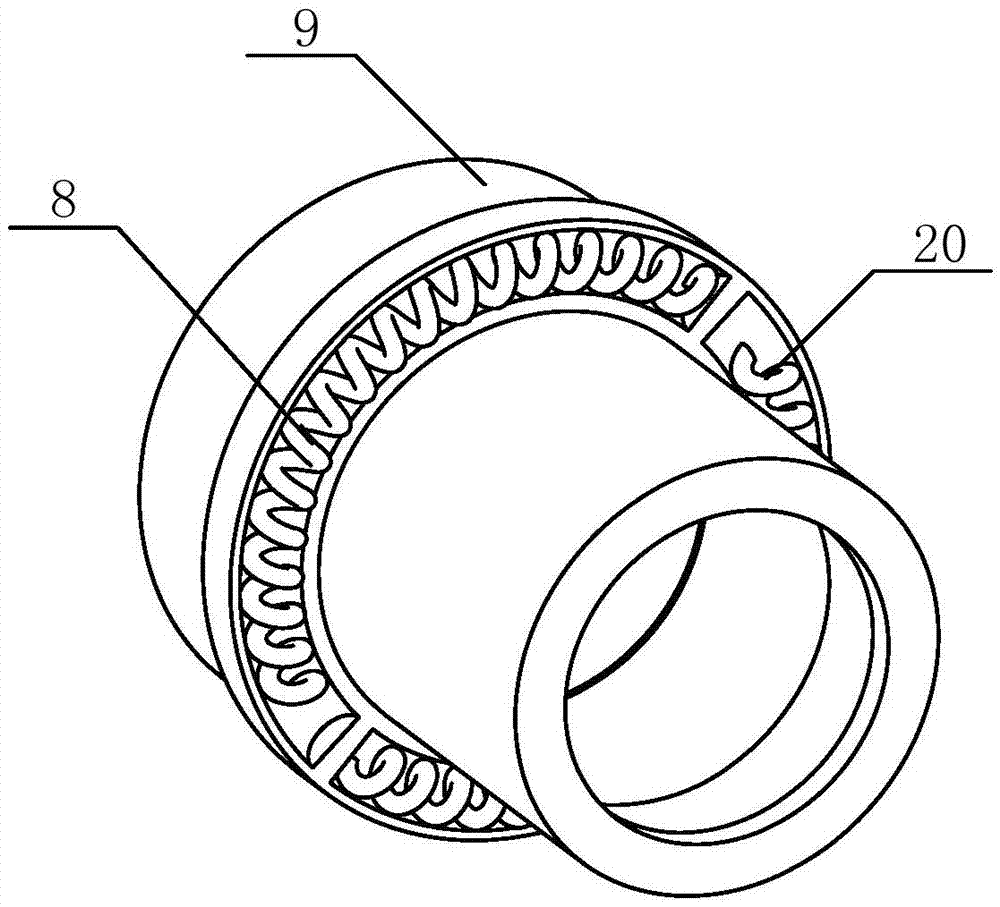

[0024] see figure 1 — Figure 4 As shown, the swing joint that utilizes the built-in bending spring to achieve force balance and mechanism limit, includes a sleeve-shaped support, and an embedded shaft assembly 7 and an embedded nested assembly 9 arranged in the support, wherein the embedded shaft assembly 7 It includes a circular shaft seat 7.1 coaxially assembled on the left side of the support, the right side of the shaft seat 7.1 is coaxially connected with a circular sleeve 7.2 that is expanded in diameter relative to the right side of the shaft seat 7.1, and the center of the right side of the shaft seat 7.1 is connected coaxially There is a support shaft 7.3 protruding from the round sleeve 7.2, and two symmetrical positions on the side wall of the shaft seat 7.1 are respectively provided with threaded holes 7.4 along the central axis of the shaft seat 7.1, and the right ends of the threaded holes 7.4 pass through the left side of the round sleeve 7.2 and the round slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com