Spindle unit

A spindle and rotor technology, applied in the field of spindle units, can solve problems such as lack of equipment, and achieve the effects of low production cost, compact design, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

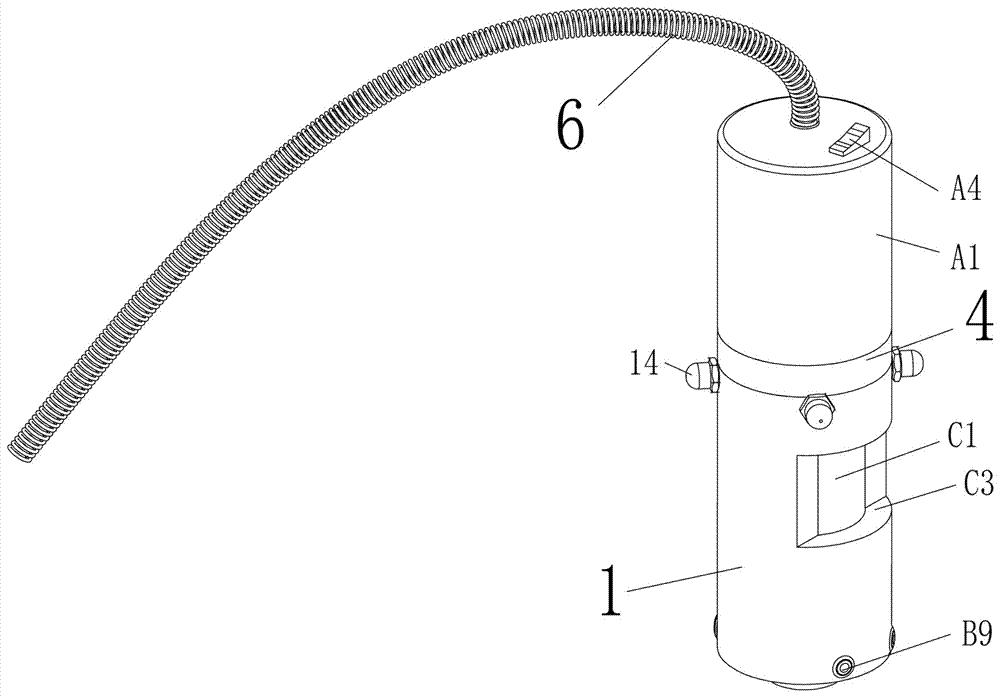

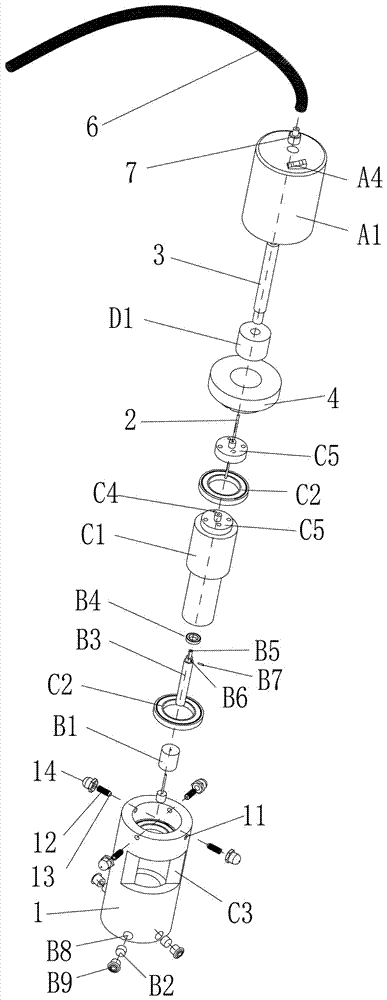

[0034] Implementation mode one, refer to Figure 1 to Figure 4 , the spindle unit is used to shape the fiber material line. Multiple spindle units can be arranged in an array to form the core part of the production equipment. The spindle unit includes a shell (1), and the inner cavity section of the shell (1) can be There are many geometric forms, but for the sake of mechanical processing, matching with other parts during use, and use efficiency, the cross section of the inner cavity is circular, and the housing (1) is equipped with a stator mechanism that is always kept non-rotating. The stator A shaft (2) is fixed on the mechanism. The cross section of the shaft (2) is circular, elliptical or polygonal. The shaft (2) runs through a rotor mechanism, and the material line passes through the feeding mechanism or the stator mechanism. The material line driven by the rotor mechanism rotates around the shaft (2), so that the material line is wound on the shaft (2) and is heated an...

Embodiment approach 2

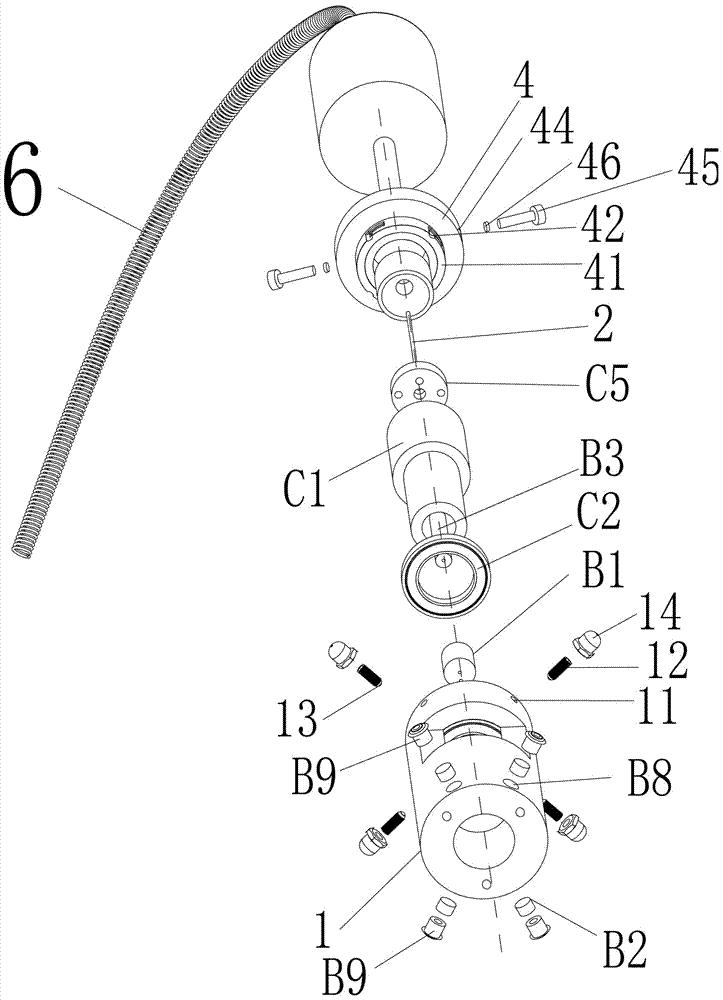

[0055] Implementation mode two, see Figure 5 , Figure 6 , the spindle unit is used to shape the fiber material line. Multiple spindle units can be arranged in arrays and combined to form the core part of the production equipment, including a shell (1), the two ends of the shell are connected, and the side is provided with an opening (C3) ;

[0056] A cover (4) can be matched and sealed with one end of the housing (1), and a discharge hollow tube (3) is fixed in the middle of the cover (4); the discharge hollow tube (3) is covered with a heating device;

[0057] A rotor mechanism, the rotor mechanism includes a rotor (C1) with a middle penetration, the two ends of the rotor (C1) are covered with large bearings (C2), the outer shaft of the large bearing (C2) is fixed on the inner wall of the housing (1), and the rotor (C1) ) is also provided with inlet holes running through both ends;

[0058] A stator mechanism, the stator mechanism includes a fixed block (B1), a magnet sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com