Self-locking nut anchoring force opening shrinking method and device

A self-locking nut and fixed force technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve problems such as difference in locking force and unqualified locking data, so as to improve stability, improve qualification rate, avoid Effect of Clamping Force Deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. But it is not used as any limitation basis for the present invention.

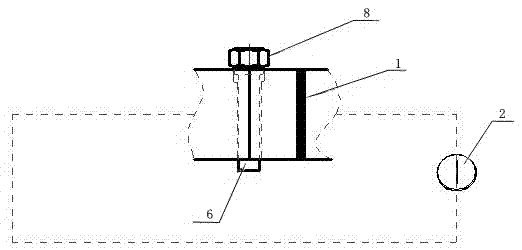

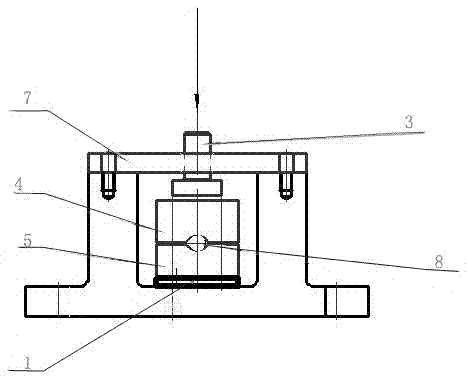

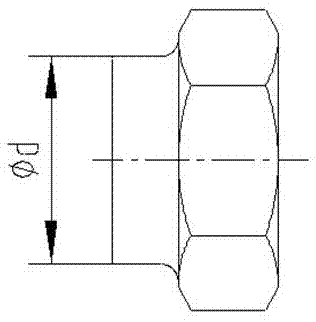

[0019] A method for closing a self-locking nut with fixed force. The self-locking nut 8 obtains a fixed closing depth under the action of a limit block 6 on a closing device; The force value signal of 1 is transmitted to the controller 2. When the force value is the same as the set force value, the controller 2 stops the closing device and continues to apply force to the self-locking nut 8. At this time, the self-locking nut 8 is at the same Substantially the same deformation resistance is produced under compression, and since this deformation resistance is the source providing the locking force, a fixed deformation resistance results in substantially the same locking force.

[0020] A self-locking nut fixed force closing device, which is refitted from a thread rolling mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com