Conductive terminal

A technology of conductive wiring and terminals, which is applied in the direction of clamping/spring connection, etc., can solve the problems of unlocking failure, weakening of terminal spring elastic force, and high difficulty of assembly, and achieve the effects of avoiding free rotation, improving reliability, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

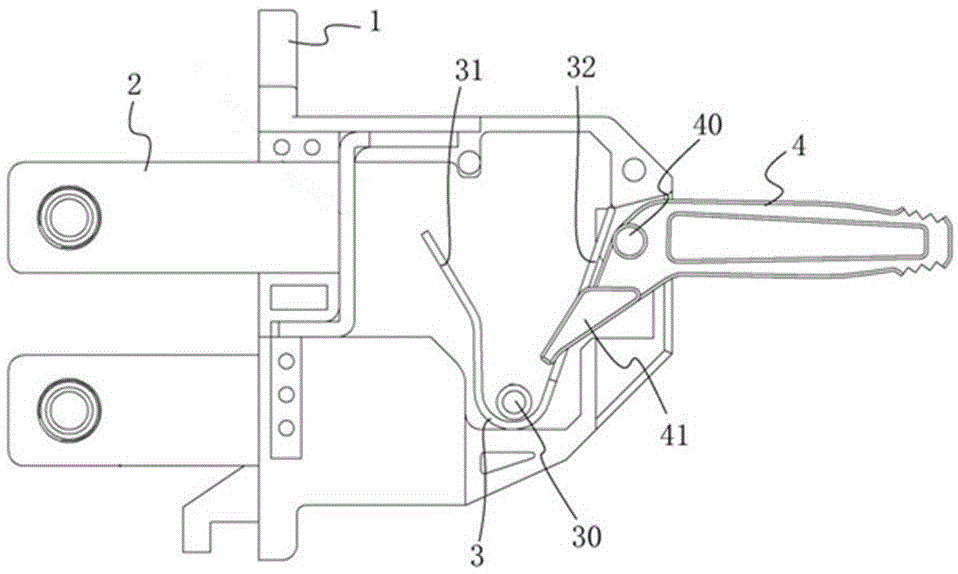

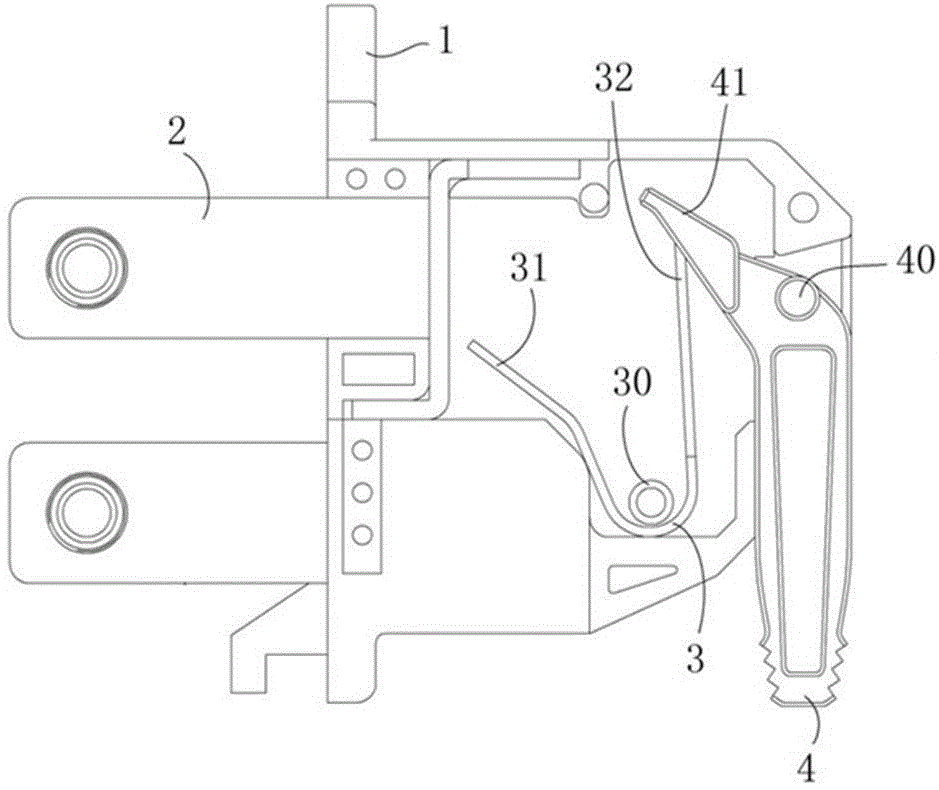

[0017] Embodiment 1 of the conductive terminal of the present invention: as Figure 1-4 As shown, a housing 1 is included, and the housing 1 is rotatably equipped with a crimping reed 3 around a rotating shaft 30 extending forward and backward. The casing 1 is also rotatably equipped with an operating handle 4 for driving the thread pressing reed 3 to rotate, and the rotation axes of the operating handle 4 and the thread pressing reed 3 are parallel. The casing 1 is provided with a threading hole 5 extending up and down and penetrating the inside and outside of the casing 1 , and the left side of the casing 1 is also provided with a conductive sheet 2 extending left and right. In this embodiment, there are two threading holes 5. Correspondingly, there are two conductive sheets 2. There are also two crimping reeds and operating handles respectively and arranged side by side. The threading holes, conductive sheet crimping reeds and The operating handles are in one-to-one corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com