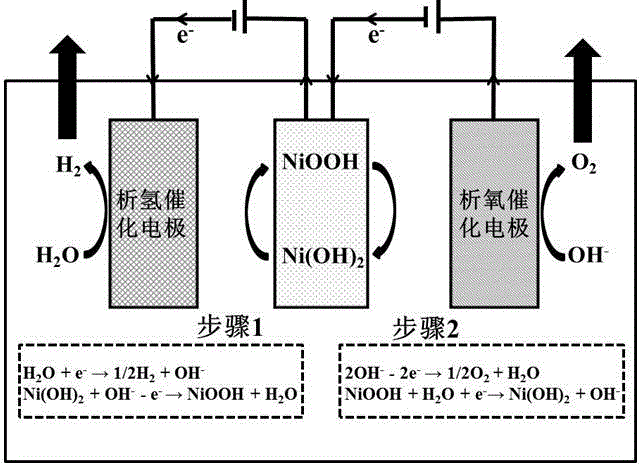

Two-step method and device for producing hydrogen through water electrolysis on basis of three-electrode system

A three-electrode system and electrolyzed water technology, which is applied in the field of electrolyzed water, can solve problems such as the effect is not very significant, and achieve the effect of reducing the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

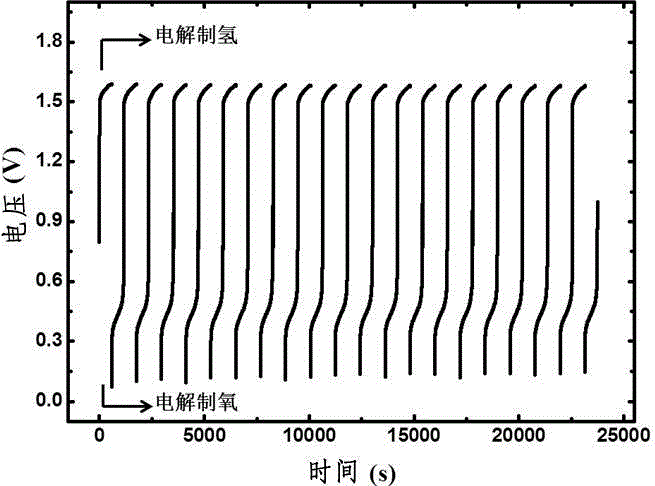

[0038]In the three-electrode electrolyzer, platinum electrodes are used for electrolysis to generate hydrogen, iridium oxide is used for electrolysis to generate oxygen, and commercial nickel hydroxide electrodes are used for nickel hydroxide electrodes. The area of the three electrodes is 20 square centimeters. The electrolytic solution uses 1 mol / liter of potassium hydroxide solution, and adopts 200 milliampere constant current to carry out electrolysis. Firstly, the cathode is connected to the platinum electrode, the anode is connected to the nickel hydroxide electrode, electrolyze with 200 mA current for 600 seconds, the average voltage is about 1.6V, and hydrogen gas is generated on the platinum electrode. Then the cathode is connected to nickel hydroxide, the anode is connected to the iridium oxide electrode, and the same 200 mA current is electrolyzed until the voltage rises to 1V, the time is 600 seconds, the average voltage is 0.5V, and oxygen is generated on the ir...

Embodiment 2

[0040] The catalytic electrode of the three-electrode electrolyzer to generate hydrogen by electrolysis uses a platinum electrode, the catalytic electrode for electrolysis of oxygen to generate oxygen uses a mixed electrode of CoO and carbon, and the nickel hydroxide electrode uses a commercial nickel hydroxide electrode that can be purchased in the market. The area of the three electrodes is 20 square centimeters. The electrolytic solution uses a potassium hydroxide solution of 1 mole per liter, and electrolyzes with a constant current of 200 milliamperes. First, the cathode is connected to the platinum electrode, the anode is connected to the nickel hydroxide electrode, 200 mA constant current electrolysis, the electrolysis time is 600 seconds, the average voltage is about 1.6V, and hydrogen gas is generated on the platinum electrode. Then the cathode is connected to nickel hydroxide, and the anode is connected to the CoO and carbon composite electrode. The same 200 mA cur...

Embodiment 3

[0042] Single-layer MoS is used as the catalytic electrode for the electrolysis of hydrogen in a three-electrode electrolyzer 2 With the graphene composite electrode, the catalytic electrode for electrolytically generating oxygen uses iridium oxide, and the nickel hydroxide electrode uses a commercial nickel hydroxide electrode that can be purchased in the market. The area of the three electrodes is 20 square centimeters. The electrolytic solution uses a potassium hydroxide solution of 1 mole per liter, and electrolyzes with a constant current of 200 milliamperes. First the cathode is connected to the MoS 2 / Graphene composite electrode, the anode is connected to the nickel hydroxide electrode, 200 mA constant current electrolysis, the electrolysis time is 600 seconds, the average voltage is about 1.65V, MoS 2 Hydrogen gas is generated on the graphene / graphene composite electrode. Then the cathode is connected to the nickel hydroxide electrode, and the anode is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com