Separation equipment with drum magnetic grate

A separation equipment and grid technology, applied in the fields of magnetic/electric field water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of limited water treatment, high manufacturing cost, complicated process, etc. To achieve the effect of ensuring the use effect and service life, cleaning thoroughly, and expanding the amount of treated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

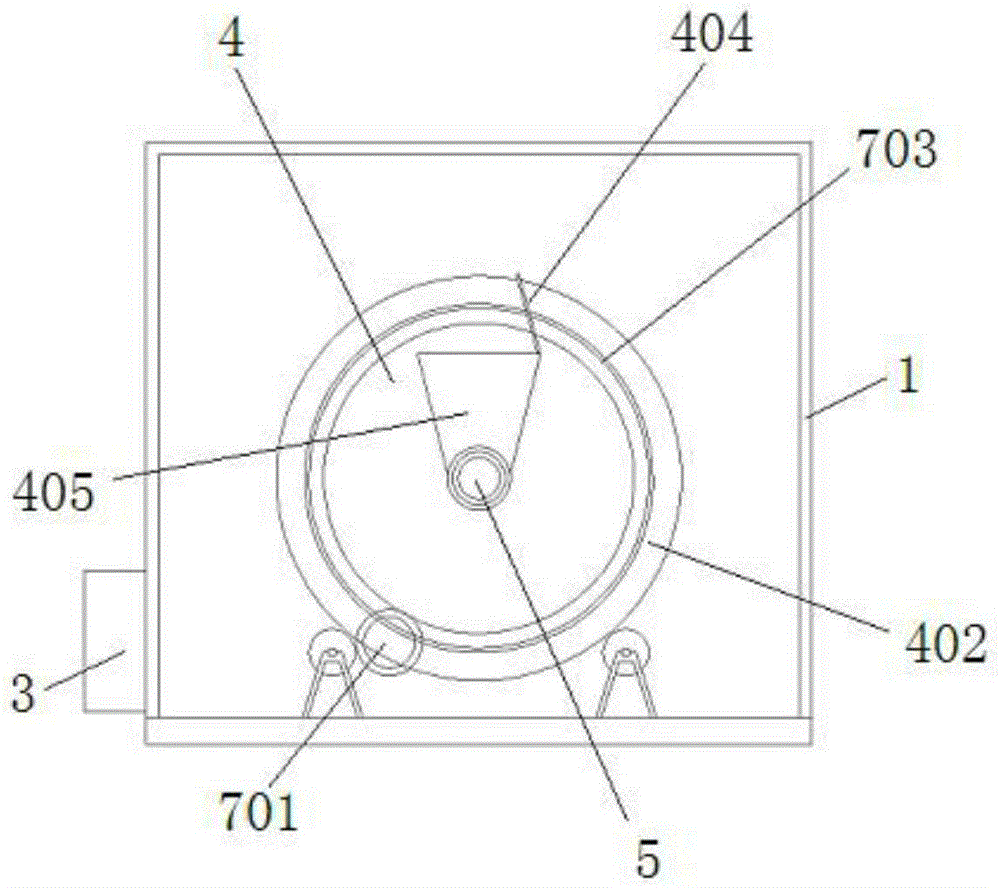

[0023] See figure 1 and figure 2 , The present invention provides a rotating drum magnetic grid separation equipment, including a box body 1 with a sewage inlet 2 and a purified water outlet 3 on the box body 1. In order to solve the technical problems described in the background art, the present invention The technical solution is that a drum magnetic grid 4 is horizontally erected in the inner cavity of the box body 1, and the sewage water inlet 2 is arranged on the side wall of the box body 1, and is in sealed communication with the drum magnetic grid 4. The grille 4 includes a grille central shaft 401 that is rotatably supported in the inner cavity of the box body 1 in a lateral direction, and a plurality of magnetic rings 402 arranged in gaps are sleeved on the grille central shaft 401, see image 3 , The magnetic ring 402 is uniformly distributed with permanent magnets 403 along the direction of the ring, and adjacent permanent magnets have opposite magnetism in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com