Super-large tonnage dry-type smoothing reactor coil demoulding lifting hook and its lifting method

A technology of smoothing reactor and super tonnage, which is applied in the field of transformer manufacturing, can solve the problems such as the inability to meet the lifting requirements and deformation of the dry-type smoothing reactor coil, and achieves a simple and practical lifting method, easy to use, and simple hook structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

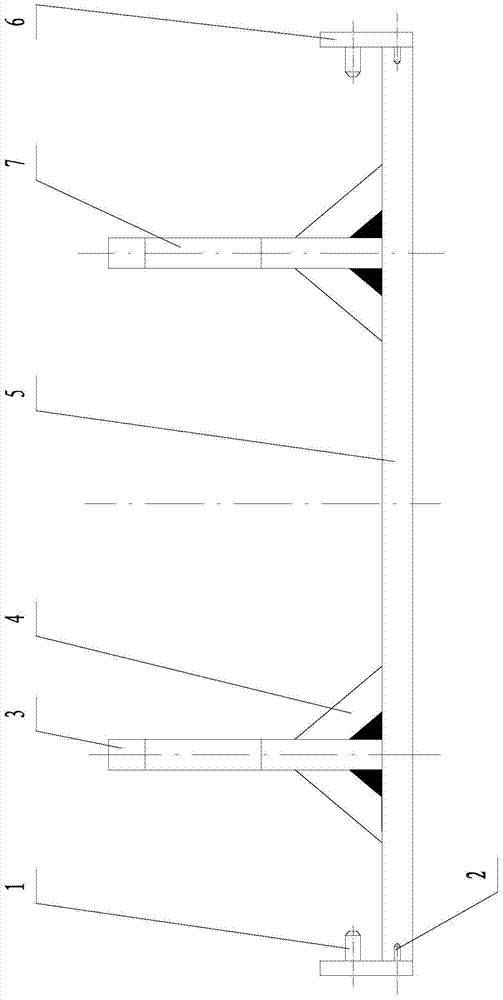

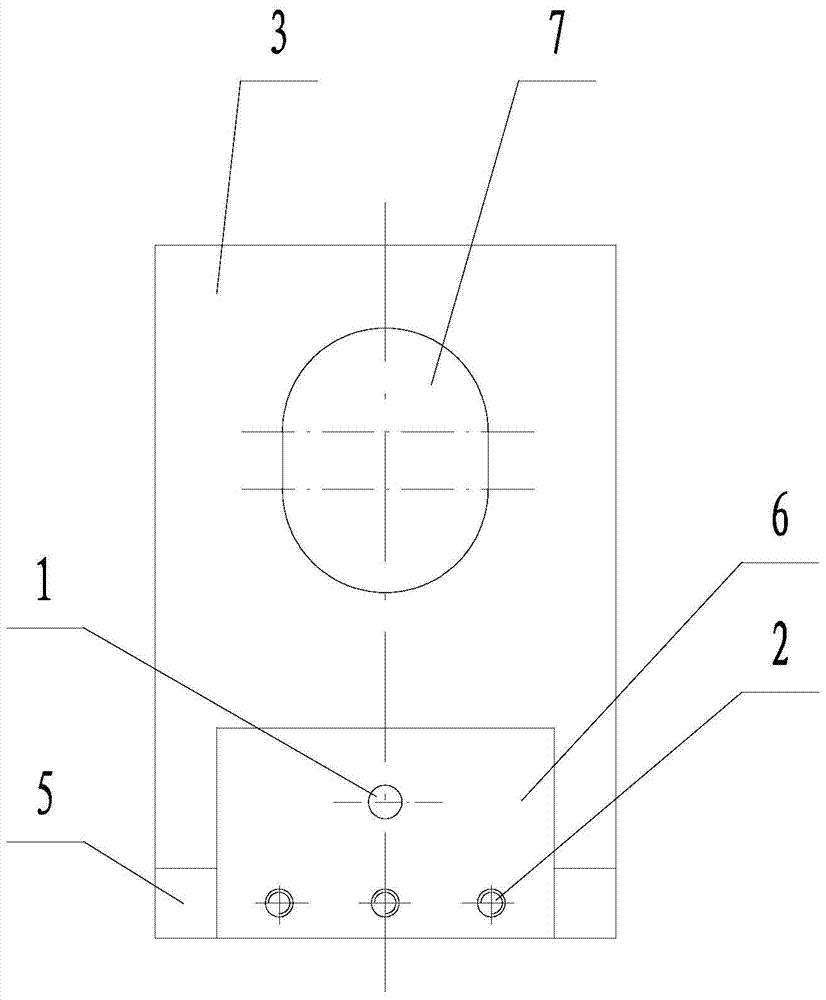

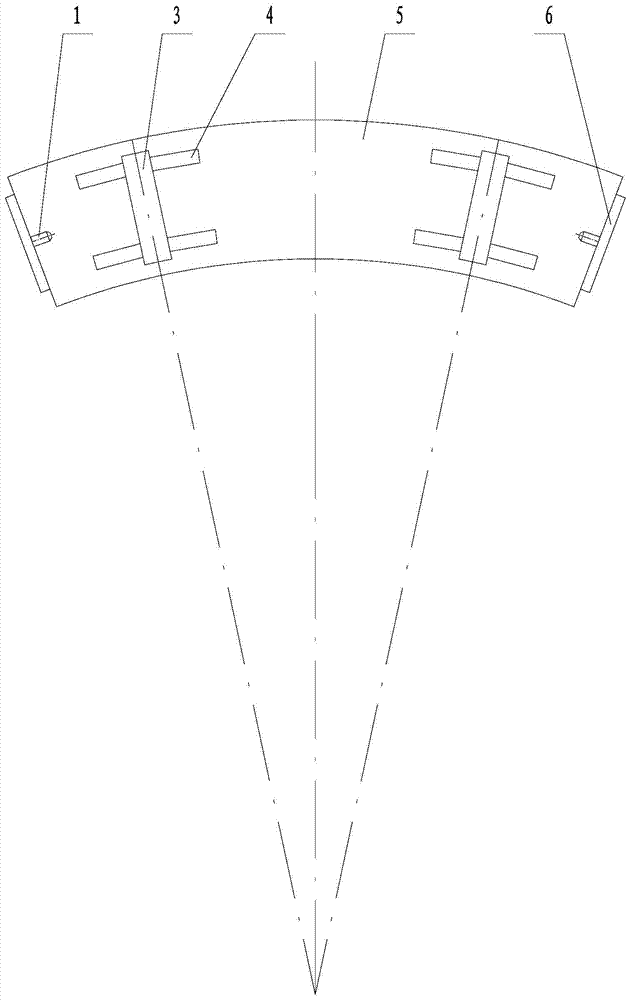

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1A ~ 1C As shown, the hook of the present invention includes a positioning pin 1, a hanging plate 3, a reinforcing plate 4, a supporting plate 5 and a baffle plate 6, wherein the supporting plate 5 is an arc-shaped plate, and the two ends of the supporting plate 5 are respectively passed through the inner hexagonal bolts. 2. A baffle 6 is fixedly connected, and the two baffles 6 at both ends can be disassembled. A plurality of hanging plates 3 with hoisting holes 7 are evenly distributed on the supporting plate 5 between the two baffle plates 6. There are hoisting holes 7, and reinforcing plates 4 for increasing strength are respectively welded between the two sides of the lower part and the supporting plate 5. The extension line of the center line of the baffle plate 6 connected to the two ends of the supporting plate 5 and the exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com