Smart warehousing mechanism and control system thereof

A storage system and storage technology, applied in transportation, packaging, storage devices, etc., can solve the problems of low automation level, low work efficiency, and high equipment operating costs, and achieve the effect of high automation level, reducing labor intensity, and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

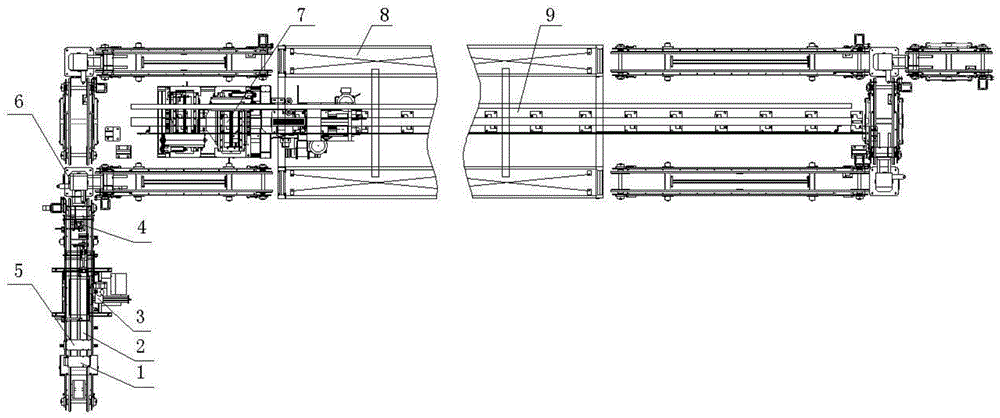

[0031] Such as figure 1 with Image 6 所示,一种智慧仓储机构,包括仓储平台和输送线;所述仓储平台由储货架8、堆垛机7和供堆垛机移动的轨道9构成,堆垛机7由堆垛机主体702、堆垛机立柱701、堆垛机抓取机构703三部分组成,其中:

[0032] 堆垛机主体702安装在轨道9上,可沿轨道9平移,负责堆垛机7的前进、后退、堆垛机抓取机构703的升降等工作,控制设备均安装在堆垛机主体702上;

[0033] 堆垛机立柱701竖直安装在堆垛机主体702上,作为堆垛机抓取机构703竖直移动的轨道;

[0034] 堆垛机抓取机构703安装在堆垛机立柱701上,可沿堆垛机立柱701竖直移动;堆垛机抓取机构703设有至少两个货叉b704,负责货物的夹取,可以进行伸、缩以及夹紧、松开等操作;

[0035] 所述输送线分为入库部分输送线和出库部分输送线;其中:入库部分输送线负责货物的测厚、扫码和贴码,并将待入库货物从入库口输送到储货架8入口;出库部分输送线完成货物信息的获取、识别,并将待出库货物从储货架8出口输送到出库口。

[0036] 储货架8为两个且对称设置,供堆垛机7移动的轨道9铺设在储货架8之间。

[0037] 入库部分输送线包括输送机2,输送机2上沿输送方向依次安装有限位装置1、测厚装置5、贴码装置3和覆标装置4。

[0038] 输送线上还安装有顶升移载机6,所述顶升移载机6完成货物的转向,衔接岔道口输送机2。

[0039] 顶升移载机6采用气缸和伺服控制,控制平稳准确。

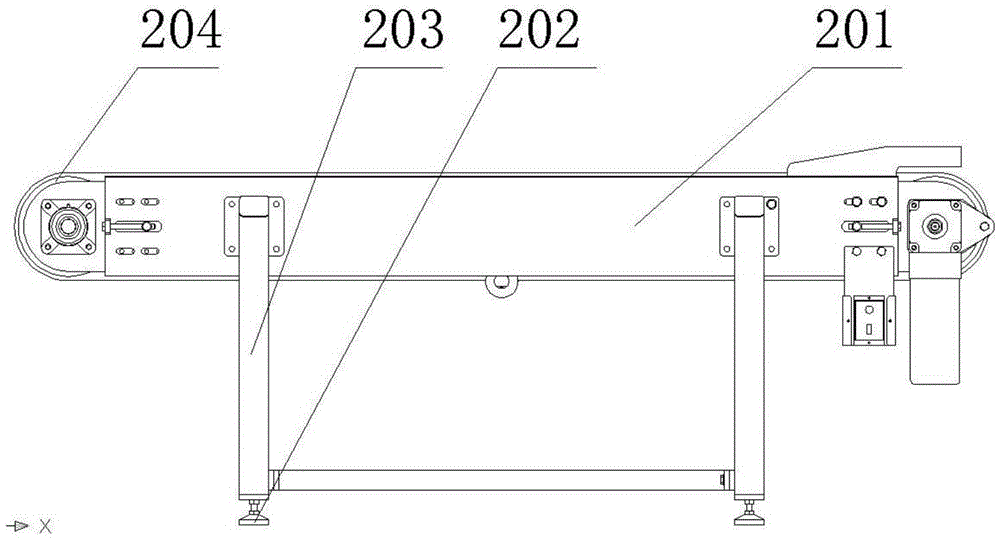

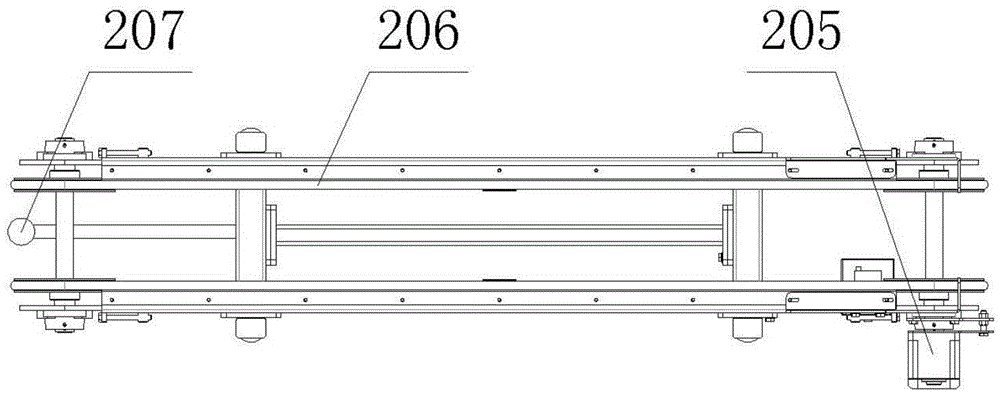

[0040] Such as figure 2 with image 3 所示,输送机2由机体201、支腿203、地脚a202构成...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com