Reciprocating type removing device

A rejecting device and reciprocating technology, applied in the field of reciprocating rejecting devices, can solve problems such as insufficient cylinder movement, waste of human resources, production line blockage, etc., and achieve the effect of improving rejecting efficiency and avoiding false rejects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

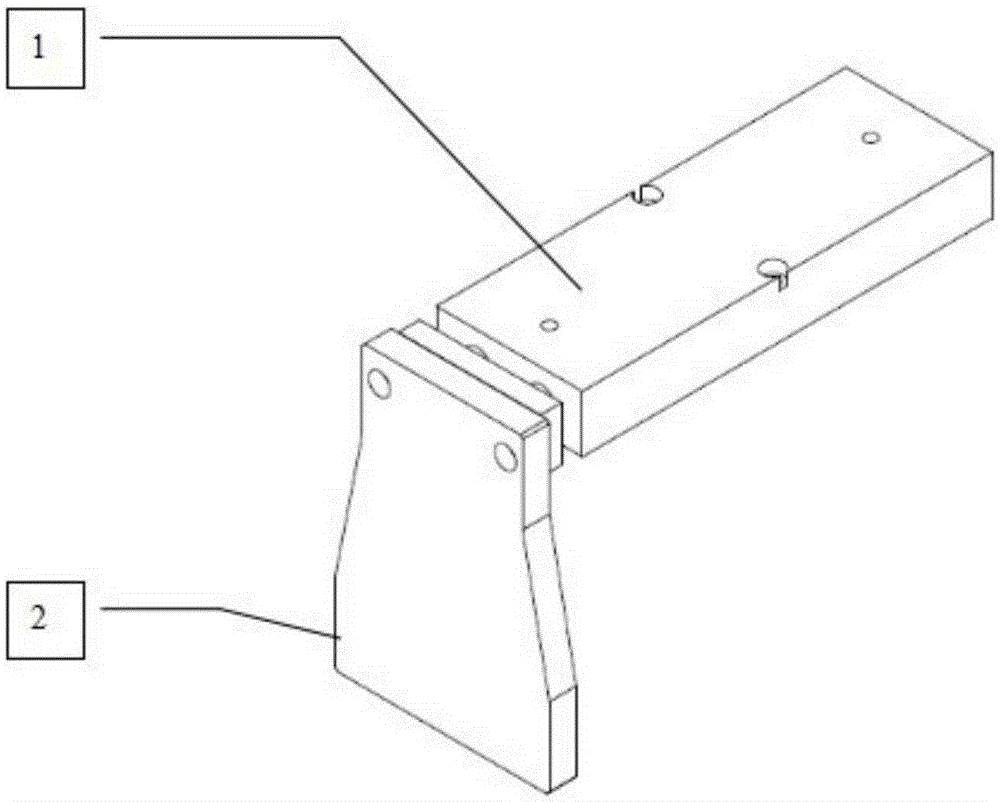

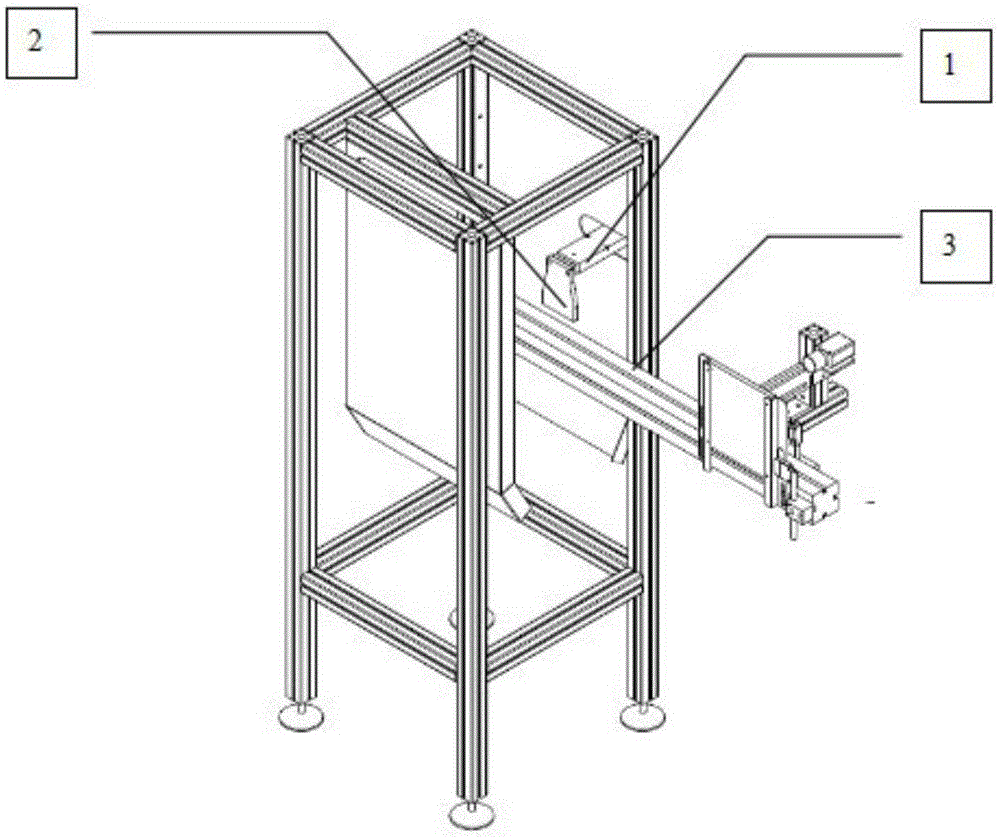

[0015] Such as figure 1 As shown, the present invention controls the cylinder (1) through the double solenoid valve, so that the cylinder (1) can reject two unqualified products during one reciprocating movement, so as to achieve the purpose of improving the removal efficiency.

[0016] The following describes the implementation process of the reciprocating rejecting device in conjunction with the accompanying drawings:

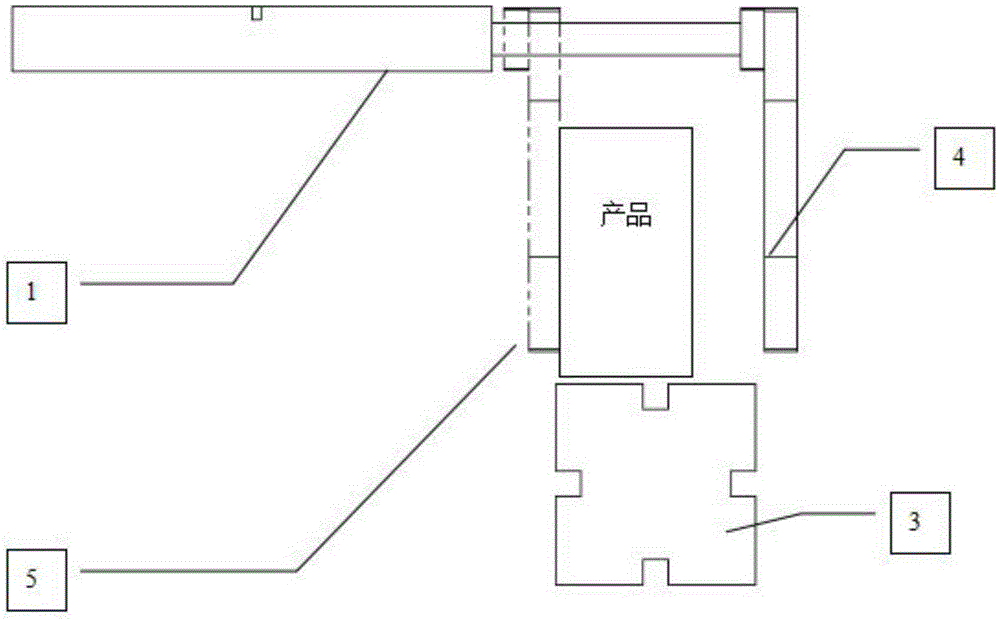

[0017] According to the actual situation of the cylinder (1) and the on-site production line, install the rejecting plate (2) on the cylinder (1). The rejecting plate (2) should be made according to the size and running direction of the actual product. After installation, when the cylinder (1) drives the rejecting plate (2) to reach the rejecting state one (4), the product can still pass through it smoothly. image 3 shown. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com