Formaldehyde purifying agent and application thereof in non-woven formaldehyde purifying wallpaper

A technology for aldehyde-purifying wallpaper and aldehyde-purifying agent, which is applied in gas treatment, construction, membrane technology and other directions, can solve the problems of troublesome capture materials, slow decomposition rate, pollution, etc., and achieve good economic and social benefits, low cost, and high technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

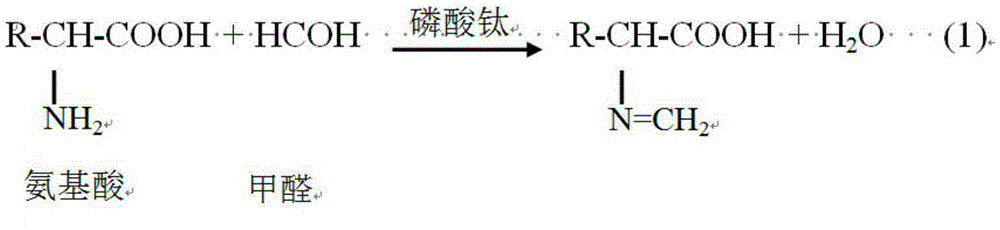

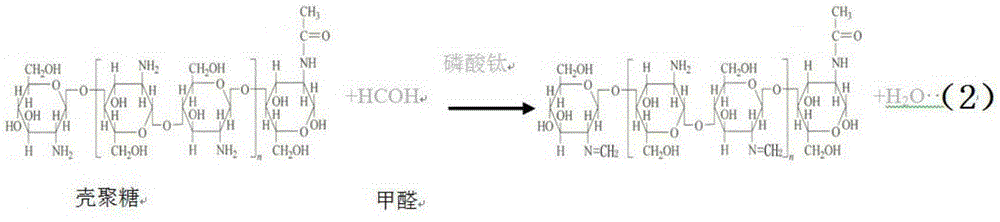

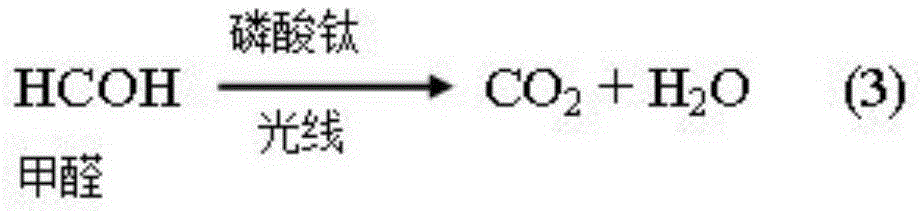

Method used

Image

Examples

Embodiment 1

[0057] A method for manufacturing a non-woven net aldehyde wallpaper, comprising the steps of:

[0058] 1) Add 100 kg of water and 30 kg of sepiolite into the reaction kettle, and stir for 10 minutes; dissolve 10 kg of aluminum sulfate in 20 kg of water, add it into the sepiolite solution at a rate of 1.0-2.0 kg / min, and continue Keep the reaction for 120 minutes; stand still for 24 hours, remove the moisture in the upper layer, and obtain 70 kilograms of a solution containing 35 kilograms of adsorbent.

[0059] Add 2.0 kg of chitosan to 33 kg of water, stir to dissolve, add 3.5 kg of glutamic acid, 1.5 kg of titanium phosphate, and continue stirring for 60 minutes; add the above 70 kg of adsorbent solution to make 110 kg of aldehyde-cleaning agent solution .

[0060] The active ingredient content of the aqueous solution of the aldehyde netting agent is 38.2wt%.

[0061] Aldehyde net agent raw material quality parts consist of:

[0062] Adsorbent: 100

[0063] Glutamic aci...

Embodiment 2

[0074] A method for manufacturing a non-woven net aldehyde wallpaper, comprising the steps of:

[0075] 1) Add 100 kg of water and 30 kg of sepiolite into the reaction kettle, and stir for 10 minutes; dissolve 10 kg of aluminum sulfate in 20 kg of water, add it into the sepiolite solution at a rate of 1.0-2.0 kg / min, and continue Keep the reaction for 120 minutes; stand still for 24 hours, remove the moisture in the upper layer, and obtain 70 kilograms of a solution containing 35 kilograms of adsorbent.

[0076] Add 2.0 kg of chitosan to 123 kg of water, stir to dissolve, add 3.5 kg of glutamic acid, 1.5 kg of titanium phosphate, and continue stirring for 60 minutes; add the above 70 kg of adsorbent solution to make 110 kg of aldehyde-cleaning agent solution .

[0077] The active ingredient content of the aqueous solution of the aldehyde netting agent is 21.0wt%.

[0078] Aldehyde net agent raw material quality parts consist of:

[0079] Adsorbent: 100

[0080] Amino acid:...

Embodiment 3

[0090] A method for manufacturing a non-woven net aldehyde wallpaper, comprising the steps of:

[0091] 1) Add 100 kg of water and 50 kg of sepiolite to the reaction kettle, and stir for 10 minutes; dissolve 25 kg of aluminum sulfate in 40 kg of water, add it to the sepiolite solution at a rate of 1.0-2.0 kg / min, and continue Keep the reaction for 120 minutes; let it stand for 24 hours, remove the moisture in the upper layer, and obtain 100 kilograms of a solution containing 62 kilograms of adsorbent.

[0092] Add 5.0 kg of chitosan in 106 kg of water, stir and dissolve, add 25.0 kg of alanine, 4.0 kg of titanium phosphate, and continue stirring for 60 minutes; add the above 100 kg of adsorbent solution to make 240 kg of aldehyde net agent solution .

[0093] The active ingredient content of the aqueous solution of the aldehyde netting agent is 40.0wt%.

[0094] Aldehyde net agent raw material quality parts consist of:

[0095] adsorbent: 100;

[0096] Amino acid: 40.32; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com