noise reduction soymilk machine

A soymilk maker and noise reduction technology, which is applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve problems that affect user experience and loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

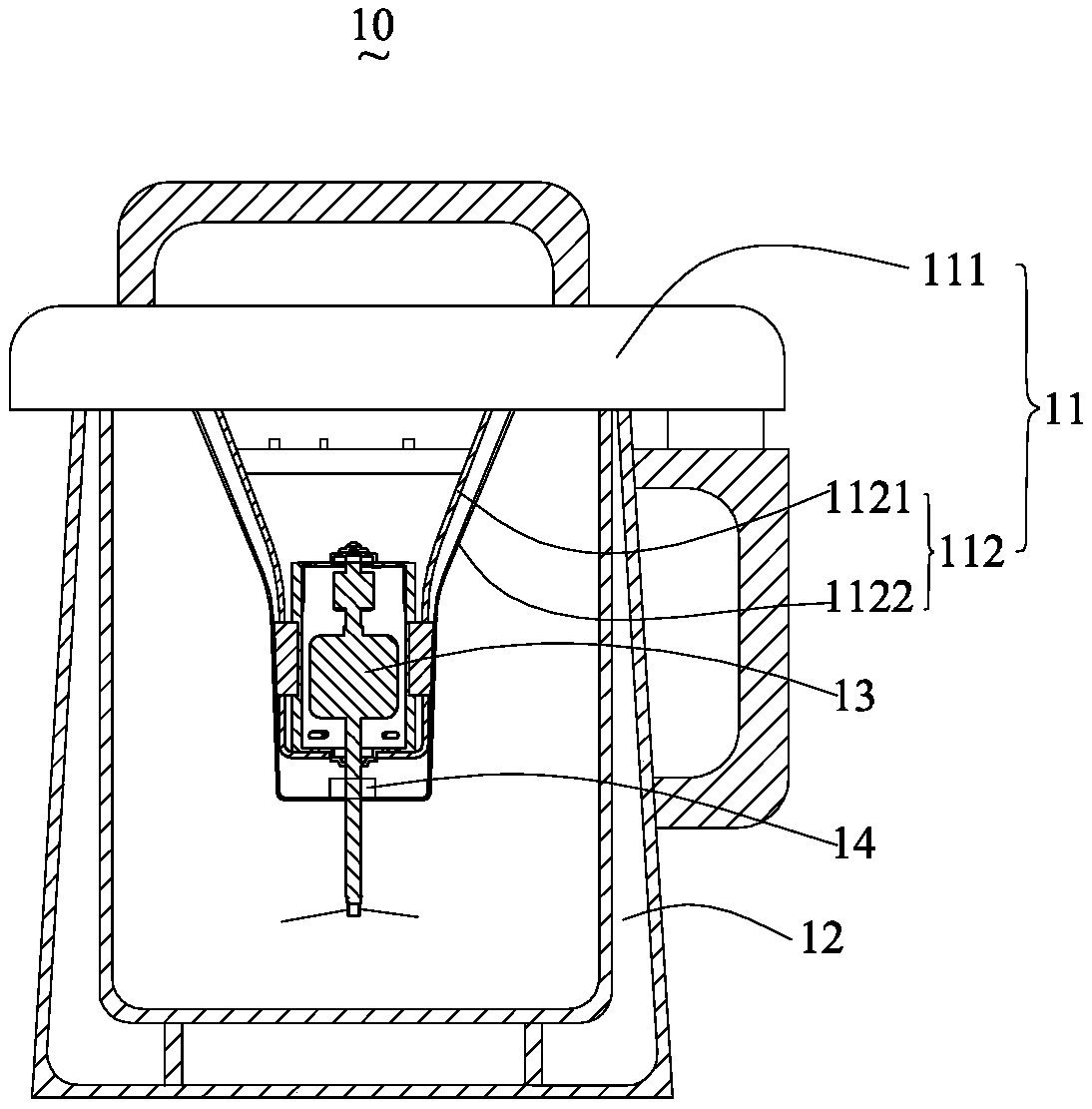

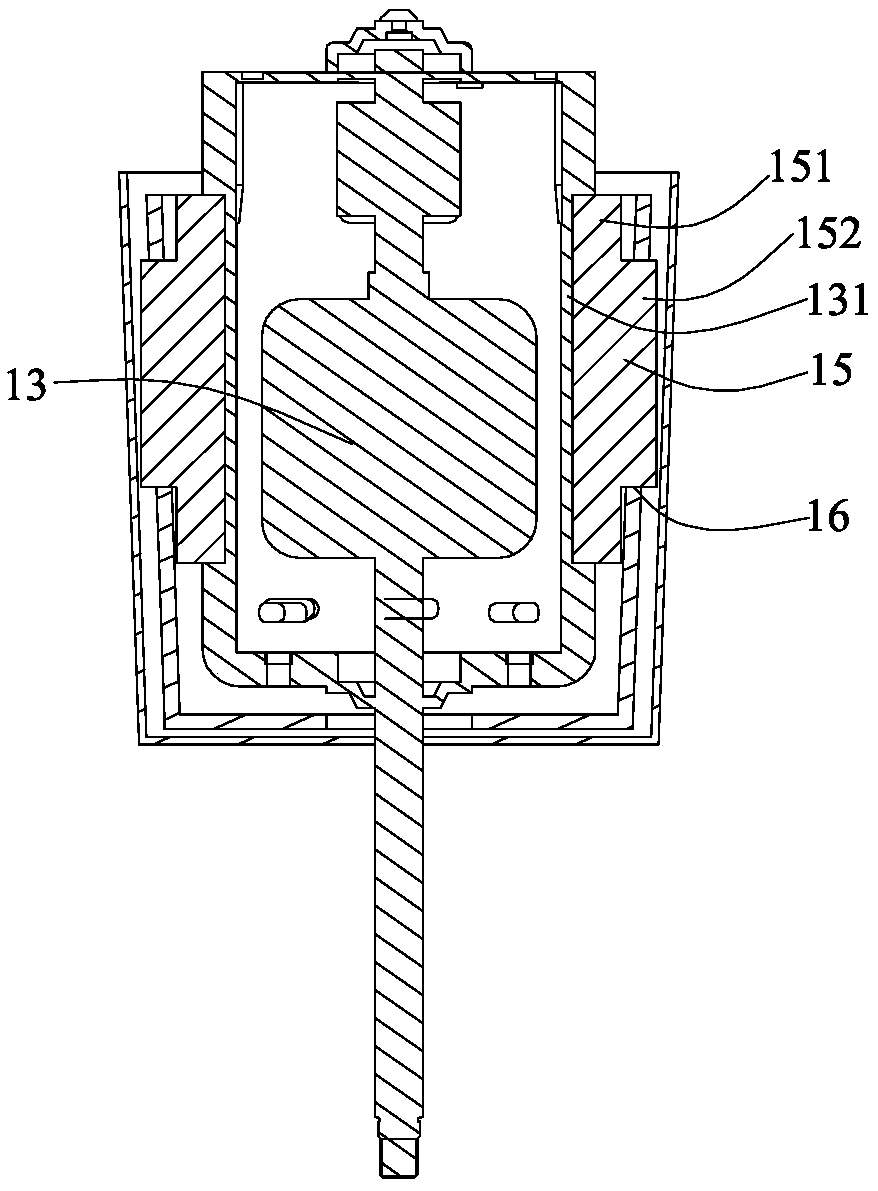

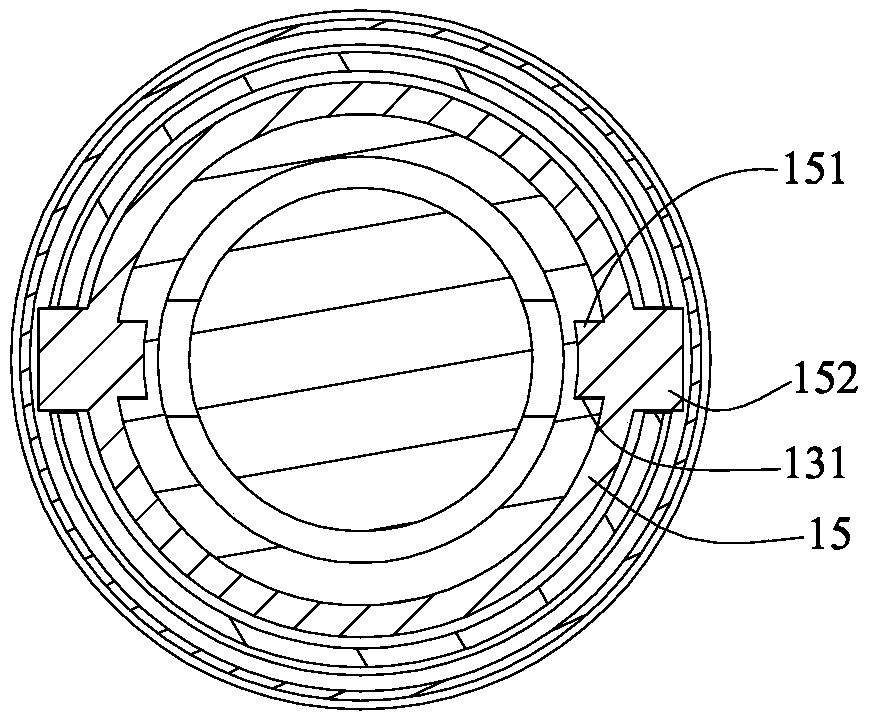

[0042] see figure 1 Shown is the first preferred embodiment of the noise reduction soybean milk machine of the present invention. The noise reduction soybean milk machine 10 includes a machine head 11 and a cup body 12. The machine head 11 is buckled on the cup body 12. Inside the machine head 11 Motor 13 is fixed, and this machine head 11 comprises machine head upper cover 111 and machine head lower cover 112, and the bottom of this machine head lower cover 112 is provided with shaft hole, and the motor shaft of motor 13 stretches in the cup body 12 through shaft hole , the motor shaft is covered with a shaft seal 14 that seals the shaft hole, an elastic mounting member 15 is provided on the side wall of the motor 13, and a mounting structure 16 is provided in the lower cover 112 of the machine head. The elastic mounting part 15 is limited and fixed in the direction and axial direction, and the motor 13 is fixed by the interference fit between the elastic mounting part 15 and...

Embodiment approach 2

[0050] see Figure 4 , Figure 5 and Image 6 Shown is the second preferred embodiment of the noise-reducing soymilk maker of the present invention. The difference between the noise-reducing soymilk maker 20 and the noise-reducing soymilk maker 10 is that the machine head lower cover 21 is a single-layer metal lower cover, and the metal lower cover There is a bracket 211 on it, the installation structure 22 is set on the bracket 211, and the fixing part 23 of the shaft sealing ring is also arranged on the metal lower cover. There is a gap between the front end of the motor and the fixing part 23 in the axial direction, and the elastic The mounting part 24 is a ring structure wrapped around the side wall of the motor 25 .

[0051] The motor 25 is provided with bumps 251 , and the bumps 251 are evenly distributed on the outer wall of the motor 25 . In this embodiment, there are two bumps 251 . The ring structure is provided with a mounting groove 241 corresponding to the prot...

Embodiment approach 3

[0055] see Figure 7 and Figure 8 Shown is the third preferred embodiment of the noise-reducing soymilk maker of the present invention. The difference between the noise-reducing soymilk maker 30 and the noise-reducing soymilk maker 10 is that the notch 31 is a U-shaped groove, and the installation structure also includes a tablet press 311 , the elastic mounting part 32 is axially limited and fixed by the pressing piece 311 , and the notch 31 is circumferentially limited and fixed on the elastic mounting part 32 .

[0056] In this way, the structure is simple and the installation is convenient.

[0057] It can be understood that the elastic mounting member can also be axially limited and fixed by means of screws.

[0058] Other structures and beneficial effects of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com