Two-electrode gas switch

A gas switch and electrode technology, applied in the pulse field, can solve problems such as short service life, and achieve the effect of improving service life, prolonging service life, and avoiding the reduction of insulation withstand voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

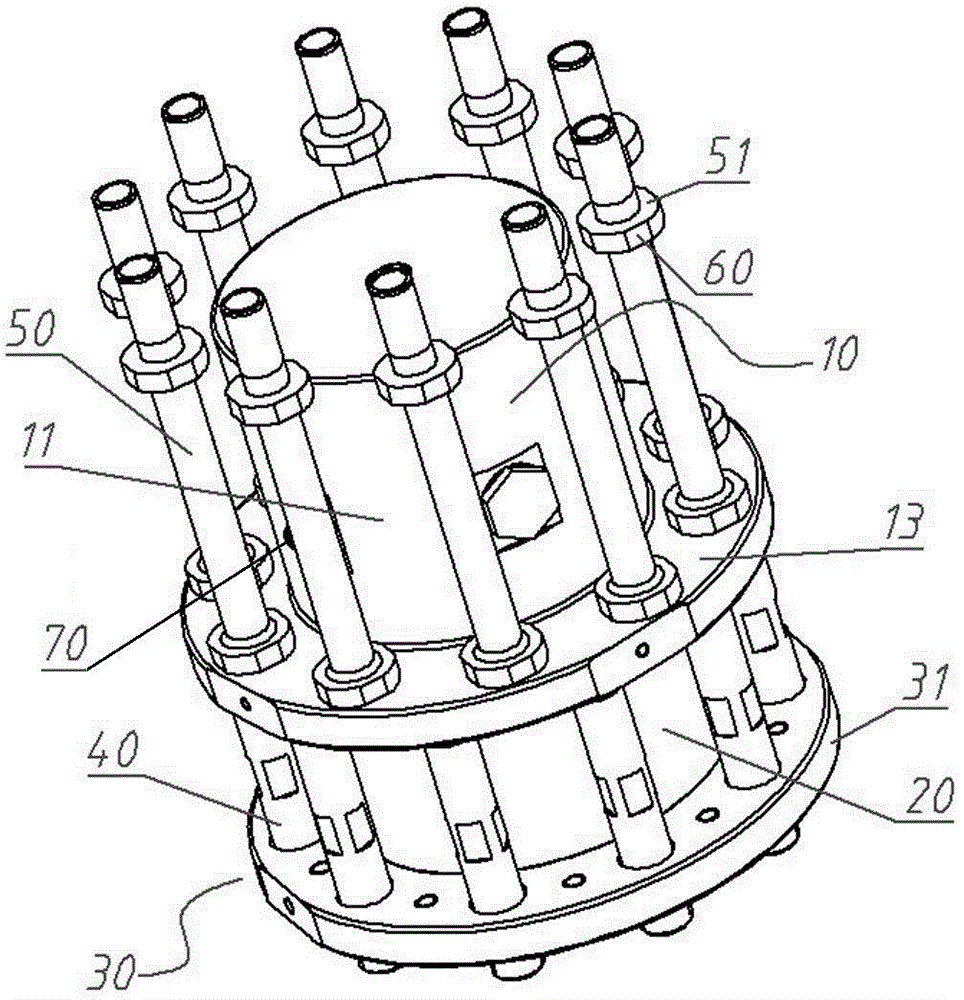

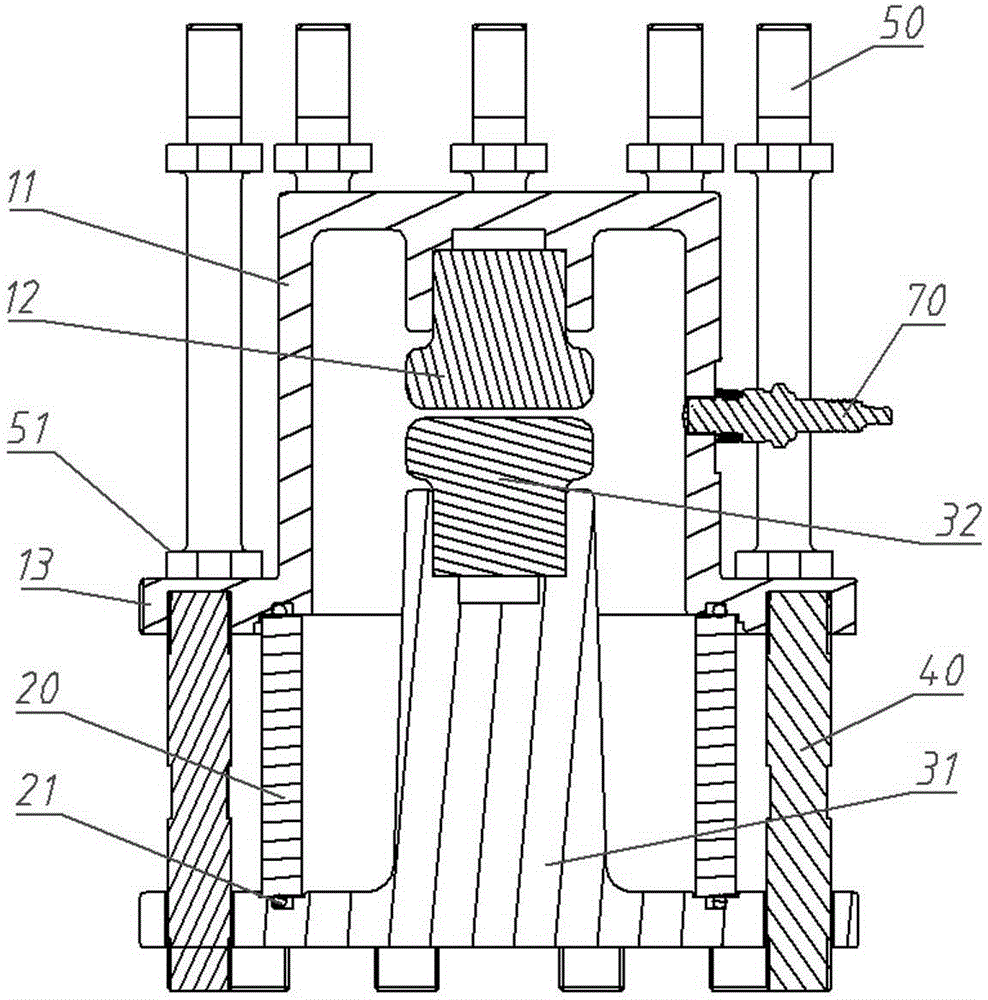

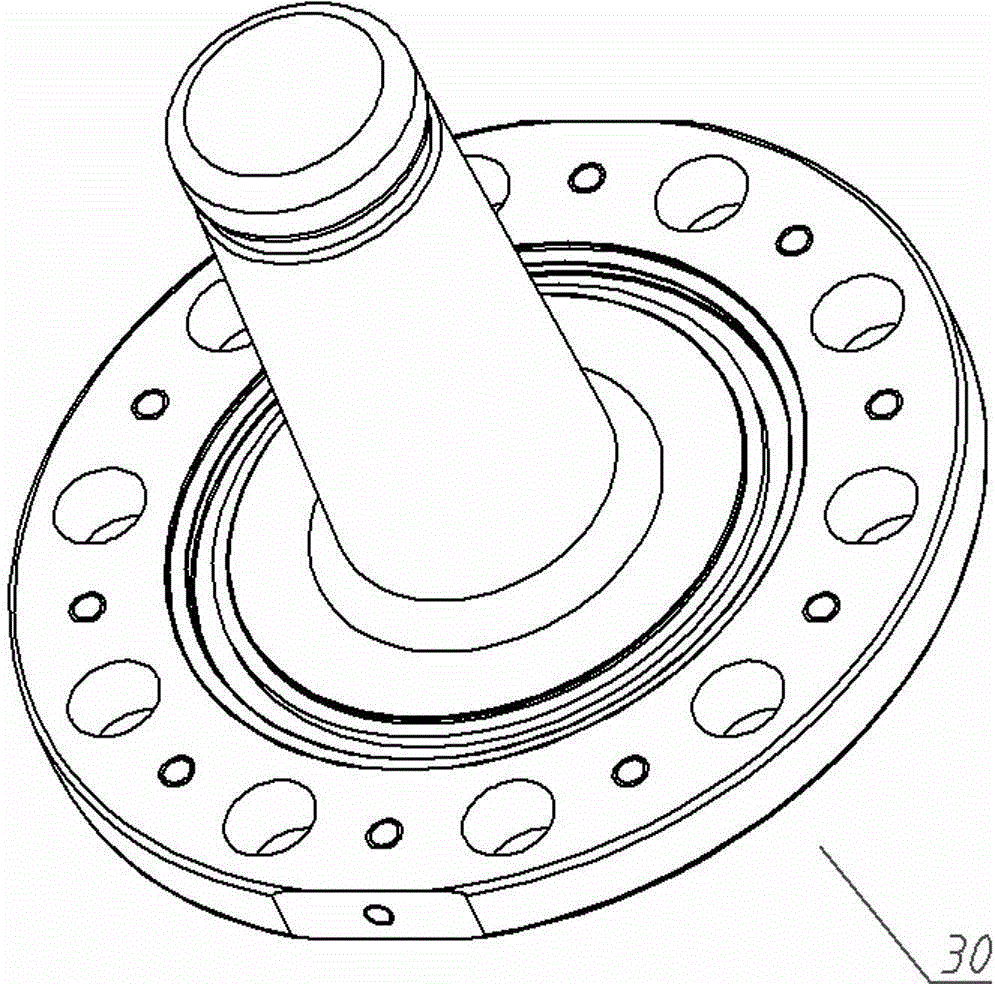

[0023] An embodiment of the two-electrode gas switch of the present invention is Figure 1 to Figure 6 As shown, it is a coaxial backflow two-electrode gas spark switch, which is mainly composed of 5 parts: an upper cover assembly 10, an insulating cylinder 20, a base assembly 30, an insulating pull rod 40 and a conductive column 50 assembly. The upper cover assembly 10 includes a first electrode seat 11 and a first electrode 12 , and the base assembly 30 includes a second electrode seat 31 and a second electrode 32 . The first electrode seat 11 is barrel-shaped with radial side walls, an upward bottom wall and a downward opening, and the second electrode seat 31 is an upside-down T-shape as a whole.

[0024] Both the base assembly 30 and the upper cover assembly 10 are made of 45# steel to ensure the structural strength, and at the same time improve the electric corrosion resistance of the flange joints of the base assembly 30 and the upper cover assembly 10 under high power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com