Wire winding instrument of detection device

A technology of detection device and twisted wire, which is applied in the field of wire twister, can solve the problems of time-consuming and laborious replacement of the detection device box maintenance socket, increase the friction force in the process of plugging and unplugging the socket and plug, and easily damage the detection socket, etc., so as to achieve convenient connection The effect of disconnection, deflection prevention and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

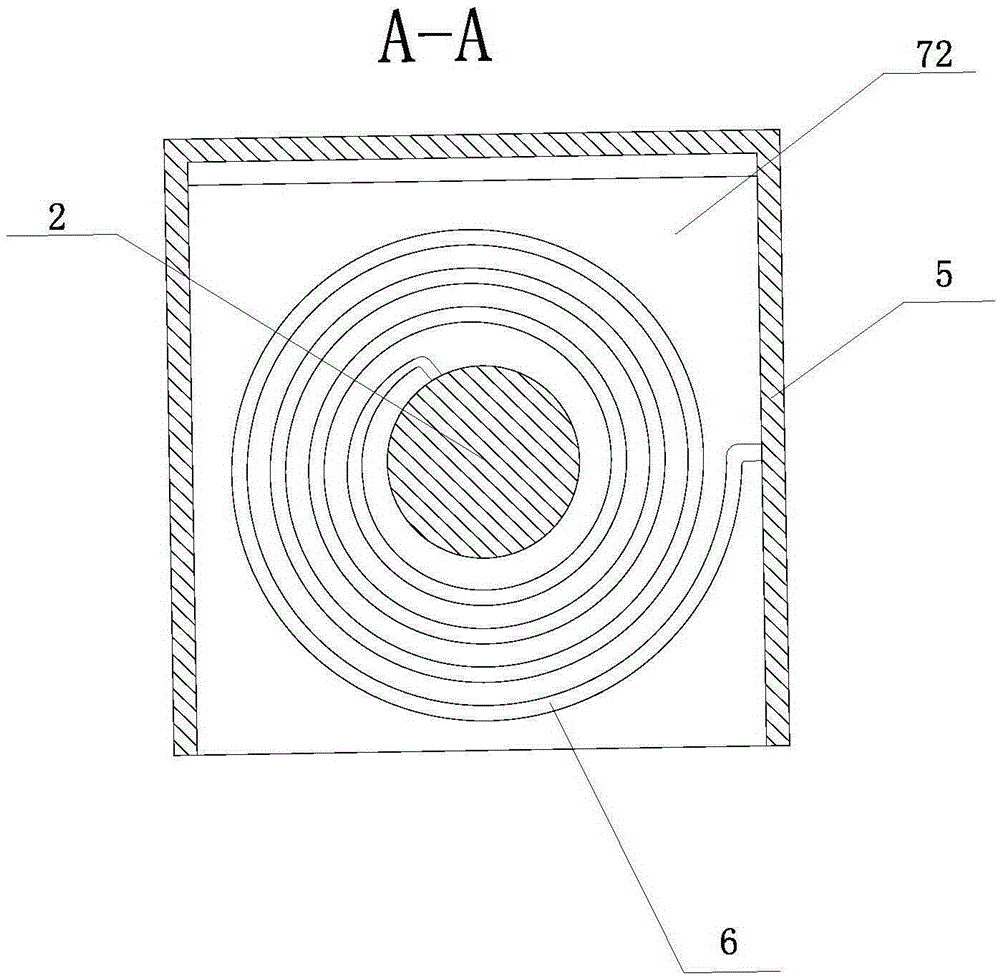

[0032] Such as figure 1 As shown, a wire stranding instrument of a detection device includes a rotating shaft 2 and a rotating shaft fixing frame 5. The two ends of the rotating shaft 2 are installed on the rotating shaft fixing frame 5 through bearings 1. The rotating shaft 2 is located inside the rotating shaft fixing frame 5 and the rotating shaft 2 can be Rotate along its own axis. The stranding instrument also includes a return spring 6 and a limit guide groove 7. Such as figure 2 , image 3 As shown, the return spring 6 extends outward in a spiral shape in the same plane; the rotating shaft 2 passes through the center of the returning spring 6 and is installed on the rotating shaft fixing frame 5 . Such as image 3 , one end of the return spring 6 is connected to the fixed shaft 5, and the other end is connected to the shaft 2. Such as Figure 4, the limit guide groove 7 includes an upper guide plate 71 and a lower guide plate 72, the upper guide plate 71 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com