A fixed furnace body gasification combustion furnace

A combustion furnace and furnace body technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of no obvious improvement in the combustion efficiency of wet garbage gasification, difficulty in increasing the amount of disposal, high manufacturing cost, etc., to achieve improved gasification Combustion efficiency, size reduction, and ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

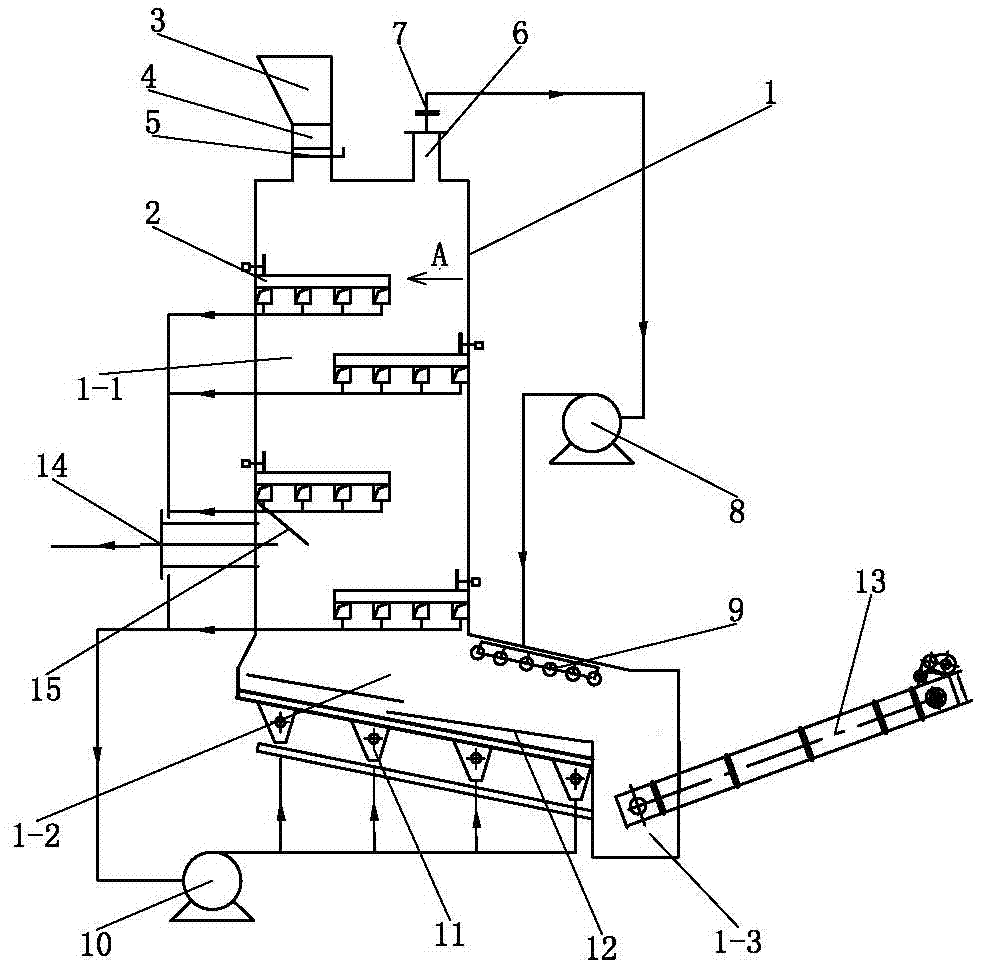

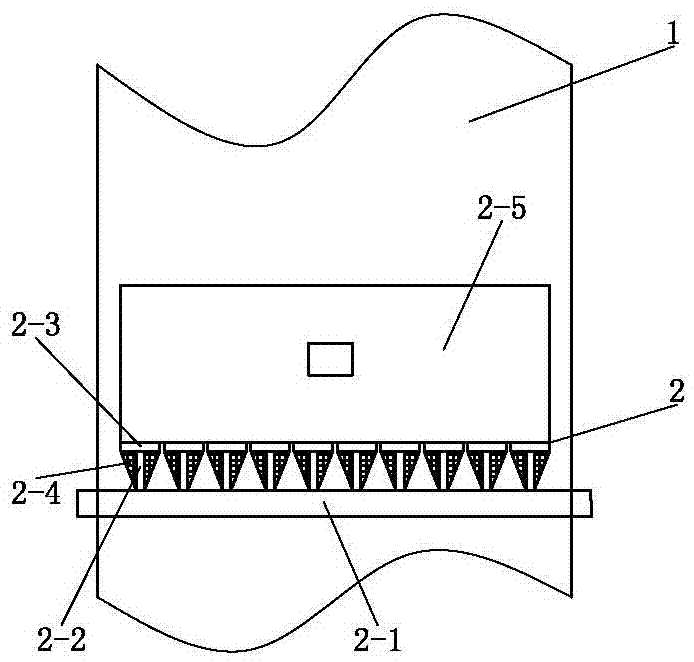

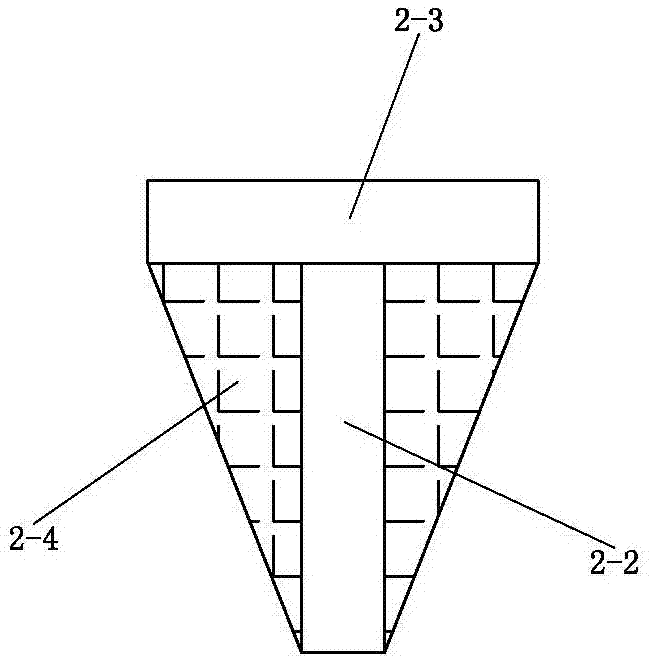

[0071] Such as figure 1 As shown, this embodiment provides a gasification combustion furnace with a fixed furnace body, including a furnace body 1, and at least one interactive charging and burning device for repeatedly discharging materials during the combustion process is provided in the furnace body 1 2.

[0072] This embodiment adopts the technical means that at least one interactive material dumping and burning device is provided in the furnace body to repeatedly dump the material during the burning process, and repeatedly dumps the material during the burning process of the wet garbage, so that the wet garbage The water evaporates easily, making the wet garbage dry quickly, and the dried garbage is easy to burn and gasify. Therefore, the gasification combustion efficiency of the wet garbage can be greatly improved, and at the same time, the size of the grate can be greatly reduced. Furthermore, the space close to the ground occupied by the fixed furnace body gasificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com