Spray nozzle for injection molding machine

A technology for injection molding machines and nozzles, which is applied in the field of nozzles for injection molding machines. It can solve the problems of increasing maintenance costs, not being able to add heating rings, and easily generating cold materials, so as to reduce maintenance costs, improve the effect of spraying materials, and prevent cold materials. The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

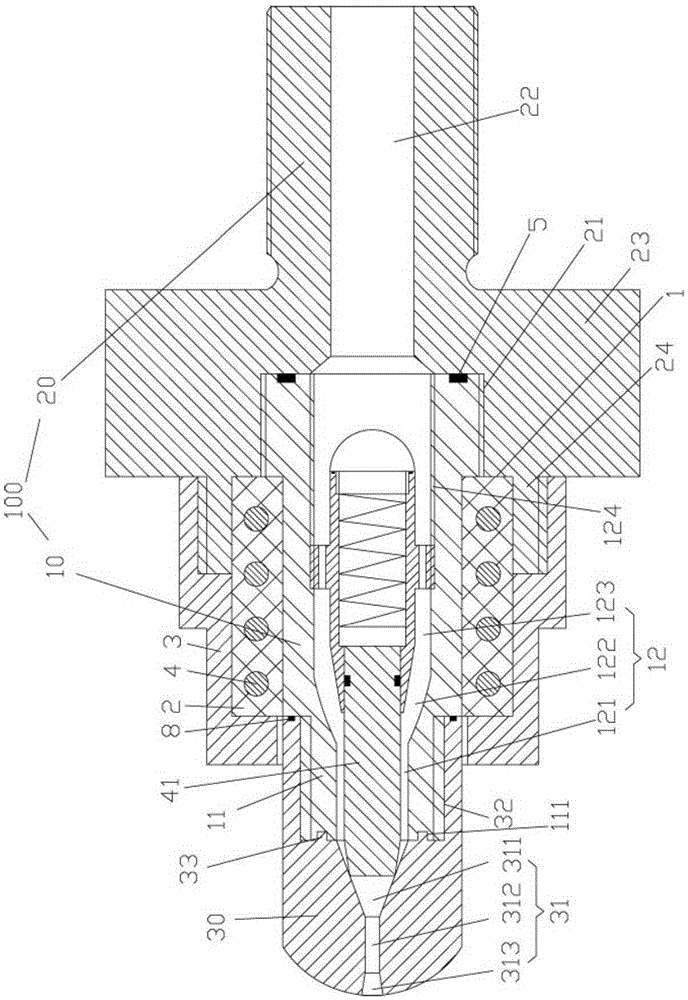

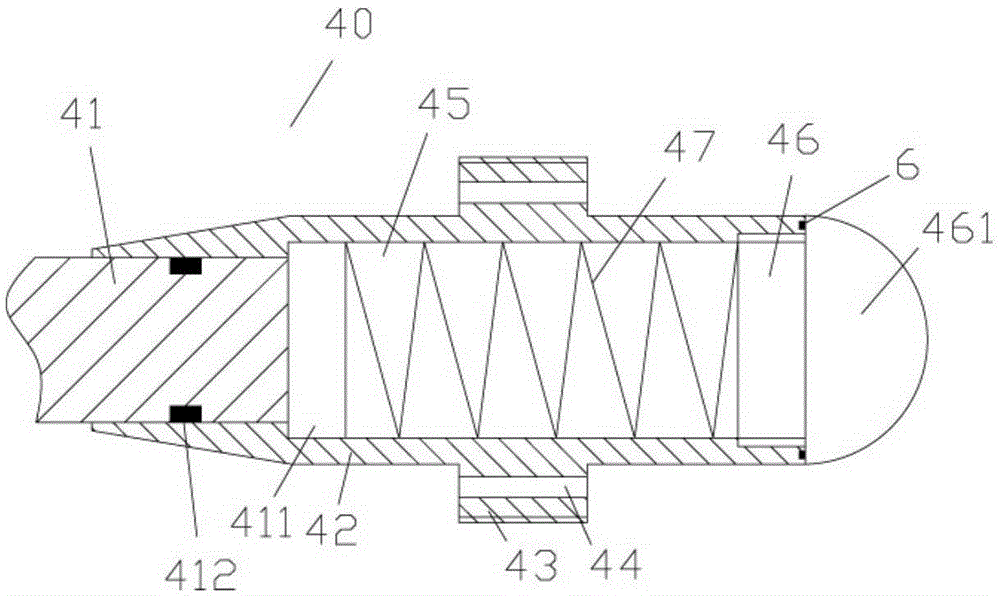

[0018] Examples, see e.g. Figure 1 to Figure 2 As shown, a nozzle for an injection molding machine includes a nozzle body 100. The nozzle body 100 includes a front nozzle body 10 and a rear connecting body 20. The middle part of the front end of the rear connecting body 20 has a threaded hole 21. The rear end of the nozzle body 10 is screwed in the threaded hole 21, the rear end of the rear connecting body 20 has a central through hole 22, the central through hole 22 communicates with the threaded hole 21, and the middle part of the front end surface of the front nozzle body 10 has a The connecting column 11 extending forward, the connecting column 11 is screwed on the nozzle head 30, the middle part of the nozzle head 30 has a nozzle hole 31, and the middle part of the front nozzle body 10 has a flow cavity 12, and the flow cavity 12 includes a front small diameter section 121, The central arc-shaped transition section 122 and the rear large-diameter section 123, the rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com