Self-energy arc extinguishing chamber for increasing thermal expansion effect

A technology of thermal expansion effect and arc extinguishing chamber, which is applied to high-voltage air circuit breakers, electrical components, electric switches, etc., can solve problems such as unfavorable pressure building and arc blowing, insufficient heating expansion chamber, etc., to improve the breaking success rate and enhance Arc extinguishing ability and effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

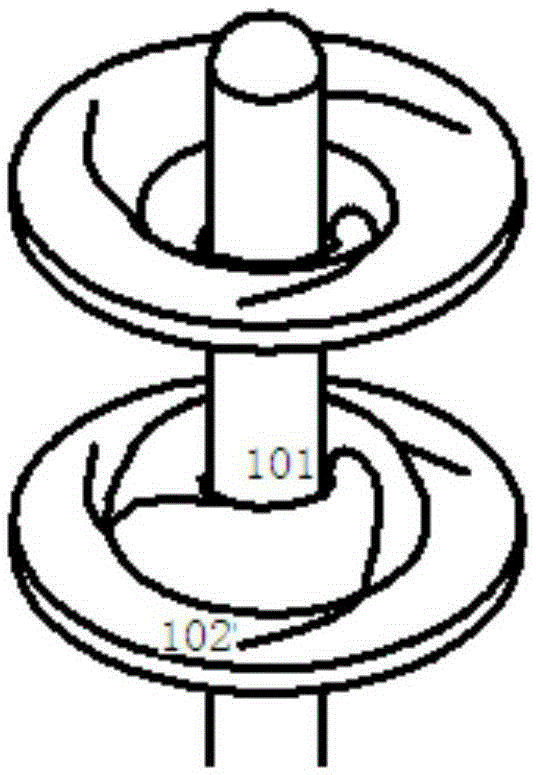

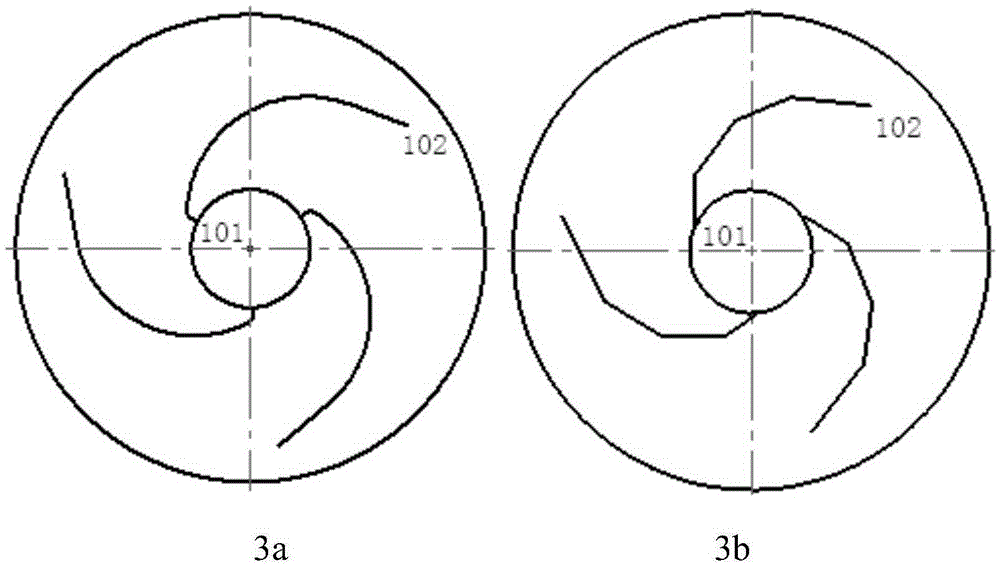

[0022] The invention provides a self-energy arc extinguishing chamber with increased thermal expansion effect. By adding an arc striking ring in the arc extinguishing chamber, the arc striking ring has several linear through grooves along the radial direction. After the arc contact transfers the arc to the arc ring, the arc ring passes current and generates a transverse magnetic field, and the magnetic field guides the arc between the two arc rings to rotate into the expansion chamber to fully heat the expansion chamber. The invention has a simple structure, can effectively improve the heating efficiency, enhance the arc extinguishing ability, and improve the breaking success rate.

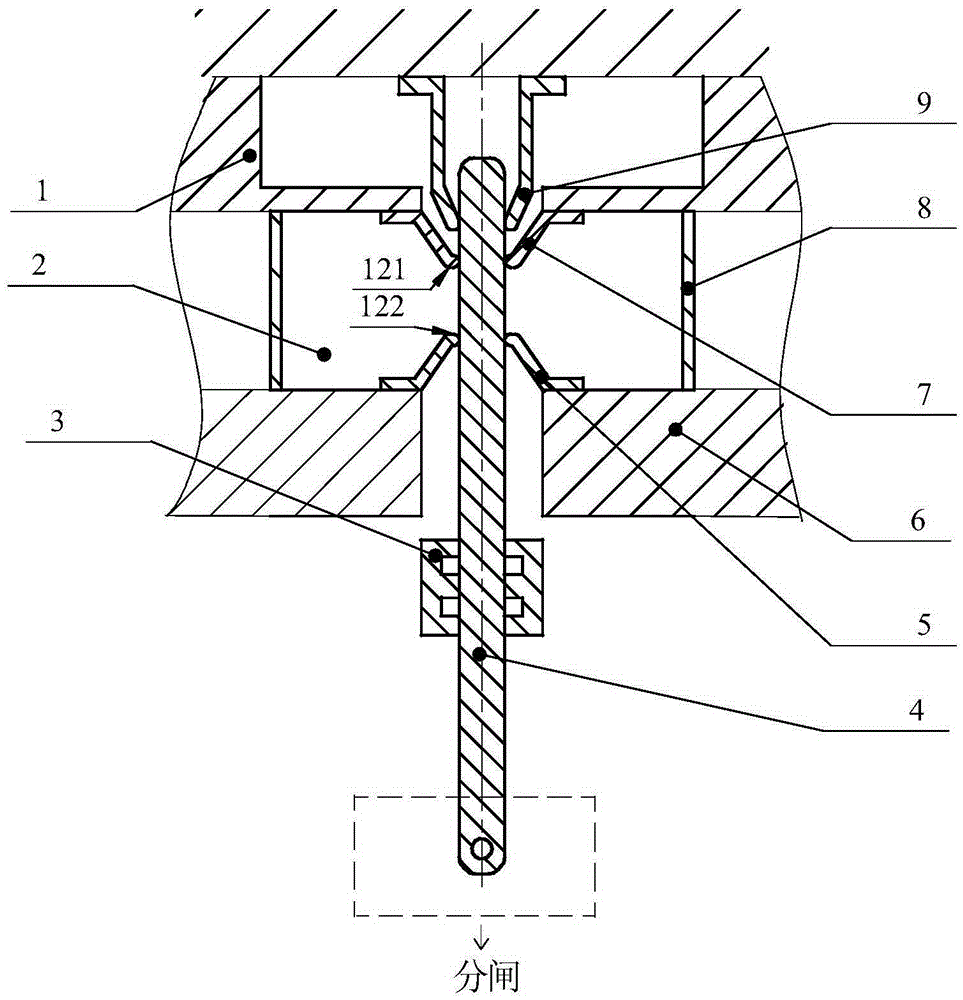

[0023] Such as figure 1 As shown, it includes an insulating cylinder 8 constituting the thermal expansion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com